Catalog excerpts

Project Profile 1-on-1 Transfer Handling Taconite Pellets Industry Great Lakes Taconite Port Application 1-on-1 transfer with 72” wide belts and a 41’ vertical drop Material Taconite (iron ore) Pellets Objective • Eliminate unloading stoppage due to emergency chute patchwork • Improve housekeeping and safety by reducing material spillage • Reduce dust generation Transfer Detail The transfer handles 10,000 tph of pellets from a Great Lakes ship unloading operation for feed to a stacking conveyor. Challenge The old chute system at a Great Lakes taconite port had been in place for many years and was a patchwork of steel that covered numerous points where material wore through the shell. Taconite pellets are highly abrasive and the maintenance on the old chute was excessive. Frequently, these repairs resulted in costly delays in ship unloading operations due to emergency patchwork that required stopping the line. Tasman Warajay Solution Flexco designed and fabricated a 1-on-1 chute that included removable hard rock liners to handle the abrasive wear of the taconite pellet. This system has been in operation for several shipping seasons with minimal maintenance required on the liners. The material flow path produces efficient material handling with little spillage of the pellets, along with minimal dust generation. Additionally, there was a high volume of pellets spilled on the ground. This caused a severe safety hazard since the pellets are spheres and pose a fall hazard to personnel walking on them. Because of this, the facility had excessive housekeeping costs to ensure the area around the chute was kept in a suitable condition. operation, and allows the facility to get ships unloaded without costly interruptions for chute repair. The unscheduled stoppages due to emergency patchwork have ended and the facility is spending minimal time maintaining the chute and cleaning up spilled material. This provides for efficient and cost effective 401 Remington Boulevard, Suite A • Bolingbrook, IL 60440 U.S.A. Tel: 1-815-609-7025 • Fax: 1-815-609-0566 ©2012 Flexible Steel Lacing Company. 03-12. For PDF: W011 www.flexco.com www.flexco.com

Open the catalog to page 1All FLEXCO catalogs and technical brochures

-

DRX™ Dynamic Bed Series

2 Pages

-

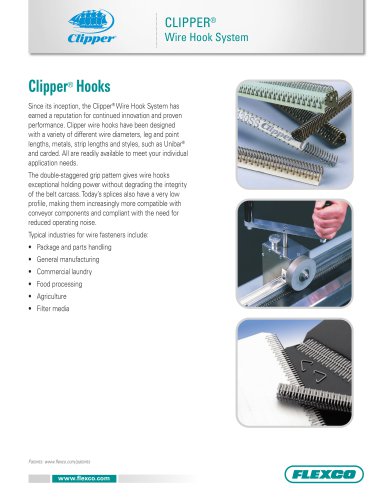

CLIPPER® Wire Hook System

12 Pages

-

CFC Secondary Cleaner

2 Pages

-

BELT-DRIVEN BRUSH CLEANER

2 Pages

-

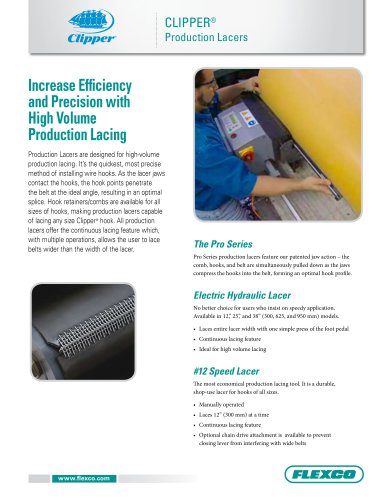

CLIPPER®

2 Pages

-

NOVITOOL®

2 Pages

-

SUPER-SCREW®

8 Pages

-

PT Smart™

2 Pages

-

TUG™ HD® Belt Clamps

2 Pages

-

Bolt Hinged Fastener System

4 Pages

-

MOTORIZED BRUSH CLEANER

2 Pages

-

Flexco SR Rivet Hinged

4 Pages

-

HV2 Precleaner with V-Tips

2 Pages

-

FGP Food Grade Precleaner

2 Pages

-

EZIB Flexco Impact Beds

2 Pages

-

electric belt cutter

2 Pages

-

DRX? 3000 Dynamic Beds

2 Pages

-

clipper® G Series Lacing

2 Pages

-

Chevron Belt Cleaner

2 Pages

-

Belt Conveyor Products Guide

24 Pages

-

BCP Overview

28 Pages

-

Belt Positioner Literature

2 Pages

-

MMP

2 Pages

-

H - Types

2 Pages

-

EZP-LS

2 Pages

-

Belt cleats

2 Pages

-

FSK Belt Skiver

2 Pages

-

SmartClamp? Belt Clamps

2 Pages

-

Far-Pul® HD® Belt Clamps

2 Pages

-

PT Smart? Tracking Insights

2 Pages

-

EZP1 Precleaner

2 Pages

-

Flexco Light Duty Products

8 Pages

-

CFMTS

9 Pages

Archived catalogs

-

2022 BELT CONVEYOR PRODUCTS

32 Pages

-

2015 BELT CONVEYOR PRODUCTS

17 Pages

-

X1642

4 Pages

-

X2088

2 Pages

-

X1893

2 Pages

-

X1207

2 Pages

-

Flexco Product Handbook

100 Pages

-

Belt Conveyor Products Handbook

103 Pages