Website:

Fives Sugar | Bioenergy

Website:

Fives Sugar | Bioenergy

Group: Fives

Catalog excerpts

Mills refurbishment on site Ovality: clevis forks fail 7 weeks to refurbish your mills* Journal of lower bearings damaged Ovality: trashplate clearance Concrete damaged Typical wear and corrosion of self settings mills *According to the number and type of (conventional or self-setting) mills to be refurbished on completion of surveys and procurement Secure / competitive services Improved performances • Use of tools designed by Fives Cail • Use and training of your own staff by Fives Cail technicians • Safe and timely on-site refurbishment • mprovement of mill efficiency and ease of operation I • erformance enhancement: capacity, extraction, bagasse moisture P Restored reliability • asier mounting / dismounting of bearings: 50 % of time saved E • No premature failure of components during campaign • Use of stainless materials • Long term sealing of the hydraulic jacks • nhanced life span of equipment: restoration of full mechanical E potential for at least 20 more years • mprovement of mechanical availability I After 20 years of service, several factors such as operating wear and tear and corrosion begin to affect the mill tandem. Fives Cail has developed an on-site refurbishment process which restores the performance and reliability of the mills, whether self-setting or conventional, by returning them to an “as new” condition. Simplified maintenance With more than 20 self-setting mill refurbishments since 2000, the spares and services department of Fives Cail has acquired a worldwide reputation in terms of service quality and of results. Driving Progress

Open the catalog to page 1

Mill being refurbished, resurfacing by automatic welding of a headstock Refurbishment of single mill or complete mill tandem Recent customer service at a glance* Kenana Sugar Company M'Bandjock Cameroon Democratic Republic of the Congo 5 mills 810 x 1700 2 mills conventional Ingenio Azucarero Guabirá Procedure in 6 steps from self setting mills Prior technical survey and report • Preferably performed while mill is operating or not 2 Preparation N’Zoia Sugar Company Ltd Metahara Sugar Factory • Mill dismantling • Preparation of base • Headstock preparation, dimensional and non destructive...

Open the catalog to page 2All Fives Sugar | Bioenergy catalogs and technical brochures

-

Cail & Fletcher ZUKA®

4 Pages

-

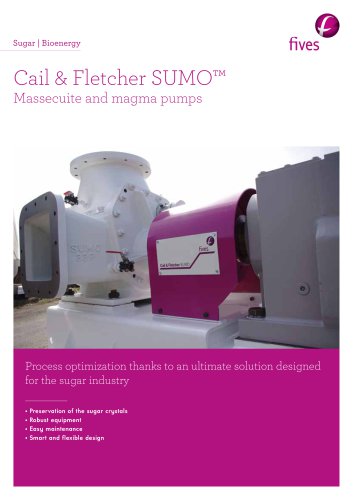

Cail & Fletcher SUMO™

4 Pages

-

Fletcher mill

2 Pages

-

Cail & Fletcher MillMax®

2 Pages

-

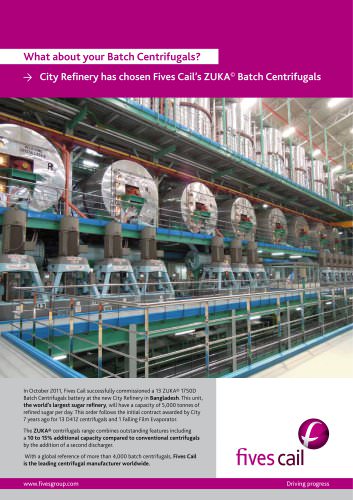

Batch centrifugals ZUKA®

2 Pages

-

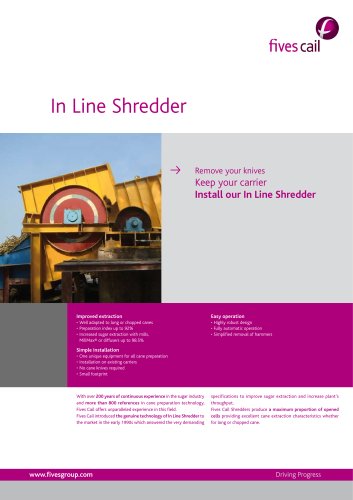

In Line Shredder

2 Pages

-

Evaporators

2 Pages

-

mill rehabilitation program

1 Pages

-

ZUKA © Batch Centrifugals

1 Pages

-

Batch centrifugal ZUKA®

2 Pages

-

Continuous centrifugal

2 Pages

-

Continuous Vacuum Pans

2 Pages

-

Massecuite pump

2 Pages

-

Probe

2 Pages

-

Multitube dryer-cooler

2 Pages

-

Falling Film Evaporators

2 Pages

-

Cane and Bagasse Diffuser

2 Pages

-

MillMax®

2 Pages

-

In-line Shredder

2 Pages