Website:

Fives Sugar | Bioenergy

Website:

Fives Sugar | Bioenergy

Group: Fives

Catalog excerpts

Fletcher short retention time clarifier Boost your clarification process Pay back your installation in the shortest time Convert your conventional clarifier Sugar losses reduction up to 65%* * Compared to conventional technologies Exceptional performance Safe operation • Short retention time • Uniform juice residence time throughout • Higher throughput • Mud density increased • Sucrose losses significantly reduced • Reduction of turbidity • No purity drop detectable • Robust design • Proven technology, many references worldwide • Simple trayless design • Collection and mud discharge fully automatic • echanical and electrical protection thanks to inverter control M of drive motor The most cost effective solution • Low operating requirements • Very low lime and flocculant quantities required For more than 200 years, Fives Cail and Fives Fletcher have been leaders worldwide, supplying the sugar and bioenergy industries with a range of equipments dedicated to sugar cane, beet and refineries. In 1972, Fives Fletcher launched his first short retention time clarifier. Since then, over 50 Fletcher short retention time clarifiers have been installed worldwide.. Fives Cail / Fives Fletcher offer • ocal or on-site manufacturing at the factory L (fast and inexpensive delivery) • imple conversion of multi-tray clarifiers to Fletcher trayless S design (operation and performance improved) • ossibility of keeping the existing control system (we can upgrade P existing systems) Our new generation of clarifiers combines now Fives Fletcher technology and Fives Cail expertise. With significantly reduced sugar losses and without loss of purity, the Fletcher short retention time clarifier is now an equipment of excellence in terms of clarification of juice. Driving progress

Open the catalog to page 1

Clarifier - Ø 10.4 m - DOMINICAN REPUBLIC Fletcher SRT clarifier features Trayless design • mproved mud settling I • asy liquidation and clarified juice removal E • mall footprint S • oundation or supports in structural steel or reinforced F contrete 2 to 4 juice tangential inlets • educed juice inlet velocity R • esigned for extremely low level of turbulence D • mproved distribution of incoming juice I Scope of supply • larifier and flash tank designs C • anufacturing M • rive unit D • loc pack unit F • pecifications for piping, instrumentation S and control system • ud pump M • ptional...

Open the catalog to page 2All Fives Sugar | Bioenergy catalogs and technical brochures

-

Cail & Fletcher ZUKA®

4 Pages

-

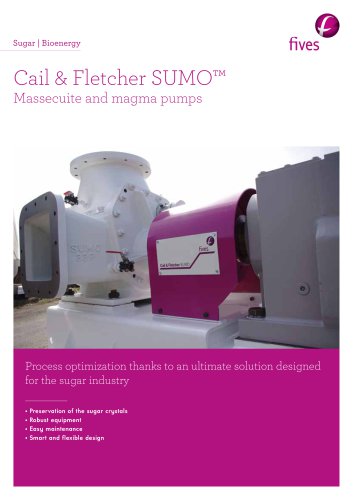

Cail & Fletcher SUMO™

4 Pages

-

Fletcher mill

2 Pages

-

Cail & Fletcher MillMax®

2 Pages

-

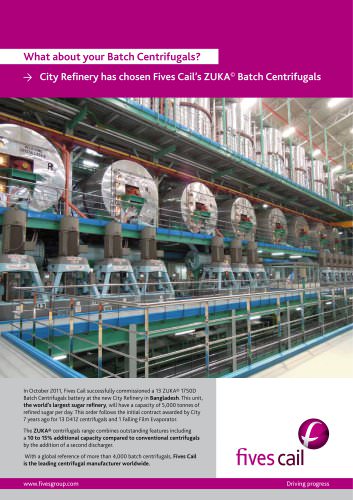

Batch centrifugals ZUKA®

2 Pages

-

Mills refurbishment

2 Pages

-

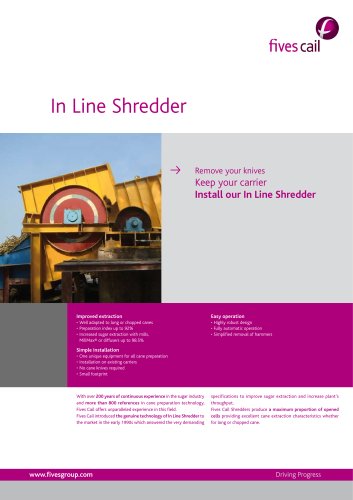

In Line Shredder

2 Pages

-

Evaporators

2 Pages

-

mill rehabilitation program

1 Pages

-

ZUKA © Batch Centrifugals

1 Pages

-

Batch centrifugal ZUKA®

2 Pages

-

Continuous centrifugal

2 Pages

-

Continuous Vacuum Pans

2 Pages

-

Massecuite pump

2 Pages

-

Probe

2 Pages

-

Multitube dryer-cooler

2 Pages

-

Falling Film Evaporators

2 Pages

-

Cane and Bagasse Diffuser

2 Pages

-

MillMax®

2 Pages

-

In-line Shredder

2 Pages