Catalog excerpts

Y696VR Series Vacuum Regulator Introduction The Y696VR Series are direct-operated vacuum regulators used where a decrease in vacuum (increase in absolute pressure) must be limited, such as between a tank and vacuum source to control vacuum in the tank. The Type Y696VR has internal pressure registration. The Type Y696VRM has a control line connection port and blocked throat for external pressure registration. Features • Precision Control of Low Pressure Settings— Large diaphragm areas provide more accurate control at low pressure settings. • Installation Adaptability—Four-position vent mounting and 360° adjustability of the union nut connection permit flexibility in vent positioning and installation in awkward positions or limited spaces. • Corrosion Resistance—Constructions are available in a variety of materials for compatibility with corrosive process gases. Principle of Operation A vacuum regulator maintains a constant vacuum at the regulator inlet. A decrease in vacuum (increase in absolute pressure) below the setpoint registers on the diaphragm and opens the disk. This allows the pressure from the higher vacuum source to pass through the regulator and restore the vacuum to its original setting. On the Type Y696VR, the controlled pressure registers directly into the diaphragm casing. The Type Y696VRM has a control line connecting the diaphragm casing to the vacuum being controlled and an O-ring stem seal blocking the throat allowing for registration only through the control line connection. Figure 1. Type Y696VR Vacuum Regulator Installation The versatility of the Y696VR Series devices permits a wide variety of installations. The body may be mounted in any position (360° rotation possible) relative to the spring and diaphragm cases just by loosening the union nut and rotating the diaphragm case. Spring case can be rotated to fit the application required. Any mounting position provides excellent performance. When exposed to the weather, spring case port should be protected by an optional umbrella vent or pointed downward to allow drainage. When indoors, pipe this port outside if used in hazardous gas service. Downstream piping will vary with the installation. To obtain the calculated characteristics, piping should be the same size as the outlet and straight for the fi

Open the catalog to page 1

Y696VR Series Specifications Body Sizes and End Connection Styles(1) See Table 1 Maximum Allowable Emergency Inlet (Casing) Pressure(2) ±15 psig (±1,03 bar) Maximum Allowable Pressure without Internal Parts Damage(2) ±8 psig (±0,55 bar) Material Temperature Capabilities(2) Nitrile (NBR): -40° to 180°F (-40° to 82°C) Fluorocarbon (FKM): 40° to 300°F (4° to 149°C) Ethyleneproplyene (EPR): -20° to 200°F (-29° to 93°C) Perfluoroelastomer (FFKM): 0° to 300°F (-18° to 149°C) Silicone (VMQ): -40° to 400°F (-40° to 204°C) Construction Materials Body: Cast iron, WCC steel (NACE), CF8M Stainless...

Open the catalog to page 2

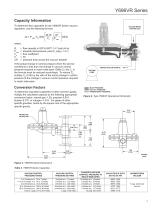

Y696VR Series Capacity Information To determine flow capacities for the Y696VR Series vacuum regulators, use the following formula: VACUUM BEING controlled = flow capacity in scfh (60°F, 14.7 psia) of air = absolute inlet pressure, psia (P1 psig + 14.7) = flow coefficient = 35 = pressure drop across the vacuum breaker If the actual change in control pressure (from the service conditions) is less than the change in vacuum control pressure required to reach wide-open (Table 2), the Cg in the formula must be reduced accordingly. To reduce Cg, multiply Cg (515) by the ratio of the actual...

Open the catalog to page 3

Y696VR Series Ordering Information When ordering, specify: Application 1. Composition and specific gravity of gas (including chemical analysis if possible) 2. Temperature range 3. Inlet pressures (maximum, minimum, nominal) 4. Pressure drops 5. Desired pressure setting or range 6. Flow rates (minimum, maximum, normal) 7. Piping size(s) Figure 4. Spring Case Port Location Refer to the Specifications section and to each referenced table; specify the desired selection whenever there is a choice to be made. Be sure to specify spring case port location from Figure 4....

Open the catalog to page 4All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages