Catalog excerpts

Product Bulletin Fisher™ 546NS Electro‐Pneumatic Transducer The Fisher 546NS transducer receives a direct‐current input signal and use a torque motor, nozzle‐flapper, and pneumatic relay to convert the signal to a proportional pneumatic output signal. Nozzle pressure, which operates the relay, is also piped to the torque motor feedback bellows. This provides a comparison between input signal and nozzle pressure and reduces errors in nozzle pressure. The transducer can be mounted on a pneumatic diaphragm control valve actuator to provide accurate operation of the valve. The integrated high‐capacity pneumatic relay eliminates the need for additional boosters or relays for operation of control valves. The transducer also can be used to provide stable operation when its output signal is transmitted to small terminal volume chambers such as control bellows in pneumatic valve positioners. Features n Vibration Resistance—High natural frequency of torque motor moving parts results in negligible vibration influence. Meets typical seismic requirements for nuclear service when a qualified seismic mounting bracket is used. n Easy Adjustment—Screwdriver adjustments for span and zero are conveniently located and have arrows indicating rotation to increase settings (as shown in figure 1). Fisher 546NS Transducer Mounted on 657 Pneumatic Diaphragm Actuator W2115 n Field‐Reversible Action—No additional parts required to reverse action. n Simple Relay Removal—Integrated pneumatic relay is mounted outside case and can be removed without disturbing electrical or pressure connections or im

Open the catalog to page 1

Product Bulletin Specifications Available Configuration Performance(4) Actuator Loading Time: see figure 3 Electro‐pneumatic signal transducer with explosion‐proof case and cover, with EPDM elastomers for use in elevated temperature and radiation environments Reference Accuracy(5): ±0.75% of output signal span Independent Linearity: ±0.50% of output signal span Open Loop Gain: 26 The 546NS can be ordered J with or J without a Fisher 67 series filter regulator. The 51 mm (2 inch) supply pressure gauge mounted on the regulator may be J 0 to 30 psig or J 0 to 60 psig range Frequency Response:...

Open the catalog to page 2

Product Bulletin Specifications (continued) Relay Diaphragm: EPDM/NomexR. Relay Valve Plug and Seat Ring: Brass Construction Materials Case and Cover: Aluminum O‐Rings: EPDM Flame Arrestors: Stainless steel Supporting Bracket/Torsion Member: Stainless steel Magnets: Alloy steel Nozzle: Stainless steel Feedback Bellows: Brass Relay Body: Aluminum Relay Restriction: Aluminum/Stainless steel Mounting Mounting parts are available for J control valve actuator mounting, J pipestand (2 inch nominal) mounting, J surface mounting, J seismic control valve actuator mounting, or J wall mounting...

Open the catalog to page 3

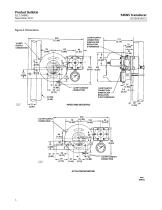

Product Bulletin Figure 2. Transducer Schematic SPAN ADJUSTMENT (MAGNETIC SHUNT) FEEDBACK BELLOWS ZERO ADJUSTMENT PERMANENT MAGNET POLE PIECES ARMATURE COIL NOZZLE ARMATURE TORSION ROD EXHAUST OUTPUT PRESSURE CENTER SPACER ASSEMBLY NOZZLE PRESSURE SUPPLY PRESSURE EXHAUST PRESSURE FIXED RESTRICTION VALVE PLUG Valve Stroking Time Figure 3. Output‐Time Relationships Figure 3 shows relative times for loading and exhausting an actuator. Exhausting times are nominally 25 percent of the loading times. Stroking time depends upon the size of the actuator,travel, relay characteristics and the...

Open the catalog to page 4

Product Bulletin Nuclear‐Service Applications The 546NS transducer is designed for nuclear power applications. The 546NS construction includes materials that provide superior performance in elevated temperature and radiation environments. The O‐rings are EPDM (ethylene propylene) and the diaphragms are EPDM/Nomex. EPDM demonstrates superior temperature capability and shelf life over nitrile. (Use a clean, dry, oil‐free air supply with instruments containing EPDM components. EPDM is subject to degradation when exposed to petroleum‐based lubricants.) The Nomex diaphragm fabric demonstrates...

Open the catalog to page 5

Product Bulletin Figure 4. Dimensions 1/4 NPT SUPPLY CONNECTION WHEN FILTER REGULATOR IS FURNISHED 1/4 NPT SUPPLY CONNECTION WHEN FILTER REGULATOR IS NOT FURNISHED PIPESTAND MOUNTING ACTUATOR MOUNTING mm (INCH)

Open the catalog to page 6

Product Bulletin Table 1. Electromagnetic Immunity Performance Port Basic Standard Test Level Electrostatic discharge (ESD) Radiated EM field Burst (fast transients) I/O signal/control Rated power frequency magnetic field 1 kV (line to ground only, each) Specification limit = ±1% of span 1. A=No degradation during testing. B = Temporary degradation during testing, but is self‐recovering. For Declaration of Conformity available in multiple languages: Table 2. Hazardous Area Classifications—CSA (Canada) Certification Body Certification Obtained Explosion-proof Class I, Division 1, Group C,D...

Open the catalog to page 7

Product Bulletin 62.1:546NS November 2017 Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user. Fisher is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of...

Open the catalog to page 8All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages