Website:

FISHER REGULATORS

Website:

FISHER REGULATORS

Group: Emerson Process Management

Catalog excerpts

Type 92B Pressure Reducing Valve • Extended Diaphragm Service Life • Two-Path Control • Elevated Actuator • Resilient Seats • Bellows Stem Guide • Double Post Stem Guide W8264 • Standard ANSI Face-to-Face Life

Open the catalog to page 1

Type 92B Introduction The Type 92B Pressure Reducing Valve is the standard steam valve for industry. The Type 92B is designed to provide decades of continuous service. It can withstand dirty operating environments while providing accurate and stable pressure control. The Type 92B is applied as a main Pressure Reducing Valve in industrial process heating applications such as heat exchangers, evaporators, digesters and reactors. Commercial applications include Pressure Reducing Valves for meter runs found in district energy systems, hot water heat exchangers, absorption chillers and boiler...

Open the catalog to page 2

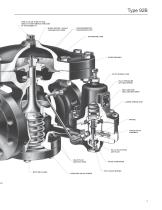

Type 92B PIPE PLUG OR TUBE FITTING DIRECTLY OVER ORIFICE FOR EASE OF ACCESSIBILITY BLEED ORIFICE - EASILY CLEANED WITH WIRE DIAPHRAGMS AND DIAPHRAGM PLATE DIAPHRAGM CASE GUIDE BUSHING PILOT SPRING CASE PILOT PRESSURE SETTING SPRING BELLOWS AND BELLOWS RETAINER LOWER SPRING SEAT CHECK VALVE ASSEMBLY PILOT VALVE STEM AND PLUG VALVE PLUG AND SEAT RING BOTTOM FLANGE VALVE STEM GUIDE PILOT VALVE SPRING REDUCING VALVE SPRING

Open the catalog to page 3

Type 92B Specifications This section lists the specifications for the Type 92B Pressure Reducing Valve. The following information is stamped on the nameplate of Type 92B: Type Number, Maximum Outlet Pressure, Maximum Inlet Pressure and Maximum Temperature. Available Configurations Pilot-operated globe-style pressure reducing valve with post guiding and flow-to-close valve plug action. Body Sizes and End Connection Styles See Table 1 Body Ratings and Maximum Inlet Pressures(1) See Table 3 Minimum Differential Pressures Required for Full Stroke(1) psig / 1.4 bar with Stainless steel spring;...

Open the catalog to page 4

Type 92B Table 1. Body Sizes and End Connection Styles END CONNECTION STYLES Cast iron Body NPT Steel and Stainless steel Body 1. Available in steel bodies only. Table 2. Outlet Pressure Ranges PILOT TYPE OUTLET PRESSURE SPRING WIRE DIAMETER SPRING FREE LENGTH PART NUMBER COLOR CODE Yellow Green Black Yellow Green Black Unpainted Unpainted High Temperature Table 3. Maximum Inlet Pressures and Temperatures BODY MATERIAL MAXIMUM INLET PRESSURE MAXIMUM TEMPERATURE Cast iron Stainless steel 1. 450°F / 232°C with standard seat ring, 600°F / 316°C with seal weld option. Table 4. Minimum...

Open the catalog to page 5

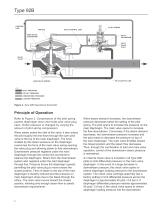

Type 92B CONTROL LINE PILOT CONTROL LINE MAIN VALVE DIAPHRAGM PILOT SPRING PILOT DIAPHRAGM PILOT VALVE PLUG VALVE PLUG MAIN VALVE SPRING PILOT SUPPLY LINE INLET PRESSURE OUTLET PRESSURE ATMOSPHERIC PRESSURE LOADING PRESSURE Figure 3. Type 92B Operational Schematic Principle of Operation Refer to Figure 3. Compression of the pilot spring pushes diaphragm down and holds pilot valve plug open. Outlet pressure is changed by varying the amount of pilot spring compression. When steam enters the inlet of the valve, it also enters the pilot supply line and flows through the open pilot valve to the...

Open the catalog to page 6

Type 92B TYPE 92B PILOT (B) TYPE 92B MAIN VALVE TYPE 92B MAIN VALVE TYPE 6492HM SAFETY OVERRIDE PILOT (A) INLET PRESSURE OUTLET PRESSURE ATMOSPHERIC PRESSURE LOADING PRESSURE INTERMEDIATE PRESSURE Figure 4. Safety Override System Schematic system, thereby preventing a high differential across the diaphragm which might otherwise cause diaphragm damage. The check valve closes and normal operation resumes when the differential pressure across the diaphragm is reduced to the proper level. Safety Override System Refer to Figure 4. Once placed in operation, the upstream Type 92B pilot (B) senses...

Open the catalog to page 7

Type 92B Installation Installation of the Type 92B is dependent on the application. As a minimum, a typical steam pressure reducing station must include a 3-valve bypass, inlet drip leg, inlet strainer (and steam separator if required) and relief valve per ASME Section VIII code. A safety override pressure reducing station can be installed in the event a relief valve is not practical as per ASME B16.122.14 standards, subject to local codes and regulations. Positioning and Mounting The Type 92B regulators are intended to be installed with their diaphragm case above the pipeline so that...

Open the catalog to page 8

Type 92B BLOCK VALVE INITIAL PRESSURE GAUGE REDUCED PRESSURE GAUGE SENSING LINE BLOCK VALVE BLOCK VALVE TYPE 92B TYPE 92B SINGLE-STAGE INSTALLATION REDUCED PRESSURE GAUGE BLOCK VALVE BLOCK VALVE INITIAL PRESSURE GAUGE SENSING LINE BLOCK VALVE REDUCED PRESSURE GAUGE BLOCK VALVE SENSING LINE BLOCK VALVE TRAP TYPE 92B SINGLE-STAGE PARALLEL INSTALLATION BLOCK VALVE INITIAL PRESSURE GAUGE BLOCK VALVE BLOCK VALVE STRAINER TRAP REDUCED PRESSURE GAUGE INTERMEDIATE PRESSURE GAUGE SENSING LINE SENSING LINE BLOCK VALVE BLOCK VALVE TRAP TYPE 92B TWO-STAGE INSTALLATION Figure 5. Type 92B Typical...

Open the catalog to page 9

Type 92B TYPE 92B MAIN VALVE TYPE 6492HM SAFETY OVERRIDE PILOT TYPE 92B MAIN VALVE TYPE 92B MAIN VALVE TYPE 92B MAIN VALVE TYPE 92B PILOT TYPE 6492HM SAFETY OVERRIDE PILOT SIDE VIEW Figure 6. Safety Override System Installation Example: Example Calculation: RELIEF VALVE SET: 15 psig / 1.0 bar FULL OPEN: 25 psig / 1.7 bar RELIEF VALVE Determine the maximum valve flow capacity at wide-open failure. CSP1 1 + 0.00065 Tsh where: Q = Steam flow rate, lb/hr P1 = Absolute inlet pressure, psia (P1 gauge + 14.7) Cs = Wide-open gas sizing coefficient, see Table 5 C1 = Flow coefficient, see...

Open the catalog to page 10

Type 92B Table 5. Main Valve Coefficients FLOW COEFFICIENTS BODY SIZE Regulating Coefficients Wide-Open Coefficients Table 6. Capacities(1) INLET PRESSURE OUTLET PRESSURE CAPACITIES IN lb/h / kg/h OF SATURATED STEAM (BASED ON 10 PERCENT DROOP) Body Size NPS 1 / DN 25 1. Printed capacities are for the Type 92B with electropneumatic loading system.

Open the catalog to page 11

Type 92B Table 6. Capacities(1) (continued) INLET PRESSURE OUTLET PRESSURE CAPACITIES IN lb/h / kg/h OF SATURATED STEAM (BASED ON 10 PERCENT DROOP) Body Size NPS 1 / DN 25 1. Printed capacities are for the Type 92B with electropneumatic loading system. Table 7. Approximate Weights BODY MATERIAL APPROXIMATE WEIGHTS WITH HIGH-PRESSURE PILOT(1) BODY SIZE Steel or Stainless steel Cast iron

Open the catalog to page 12All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages