Catalog excerpts

Buyers Guide Process Management

Open the catalog to page 1

Fisher® LP-Gas Equipment Global Technology Leadership Our commitment to providing customers with customized solutions, dependable products, along with uncompromising quality standards and exceptional service is a tradition dating back to our beginnings in 1880, when William Fisher invented the rst regulator. Today, Fisher LP-Gas Equipment is a part of Emerson Process Management’s Regulator Technologies Division, the World Leader in valve and regulator design and manufacturing. Emerson, a $24.4 billion company, invests over $800 million in research and development annually. Being a part of...

Open the catalog to page 2

TaBle of conTenTs REGULATOR APPLICATION MAP . . . . . . . . . . . . . . . . . . . . . . . . . 2 INTERNAL VALVES REGULATOR SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . .6 VALVE SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ACCESSORIES SELECTION GUIDE . . . . . . . . . . . . . . . . . . . . . . .16 RESIDENTIAL REGULATORS TWO-STAGE SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 FIRST-STAGE REGULATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 Types R122H and R622H SECOND-STAGE REGULATORS. . . . ....

Open the catalog to page 3

lP-gas RegulaToRs Application: Regulators R622 SecondStage Introduction The regulator truly is the heart of an LP-Gas installation. It must compensate for variations in tank pressure from 8 to 250 psig / 0.55 to • Corrosion-Resistant and Wear-Resistant Materials • Stainless Steel Inlet Screen • Large Drip-Lip Vent • High Capacity Relief • Easy Installation • Improved Regulation • Built-in Gauge Taps *Features Vary By Model.

Open the catalog to page 4

lP-gas RegulaToRs 17.2 bar and deliver a constant outlet pressure of LP-Gas typically at 11 inches w.c. / 27 mbar to consuming appliances. The regulator must deliver this pressure despite the intermittent use of the appliances. In propane service, NFPA 58 requires Two-Stage regulation on all xed piping systems that serve 14 inches w.c. / 35 mbar appliance systems (normally operated at 11 inches w.c. / 27 mbar pressure). Two-Stage regulation produces a nearly constant pressure to the appliance and can result in a more efcient LP-Gas operation for the dealer resulting in less maintenance and...

Open the catalog to page 5

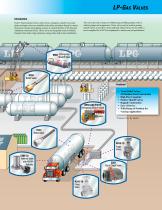

lP-gas ValVes Application: Valves and Relief Valves C477 Jet Bleed Internal™ Valve C484-24 Jet Bleed Internal™ Valve C483-24 with P723 Rotary Actuator N550 with P539A Pneumatic Actuator H722 Relief Valve C407-10 with P731 Internal Valve with Rotary Actuator

Open the catalog to page 6

lP-gas ValVes Introduction The valves provide a means of withdrawing and lling product with or without pumps and compressors. These valves may be used as primary shutoff valves, excess ow valves and back check valves. No one offers a more complete line of LP-Gas Equipment to match your job specication. Fisher® brand internal valves, relief valves, emergency shutoff valves and globe and angle valves are installed in the inlets and outlets (liquid or vapor) of pressure vessels and in piping systems to control the ow of LP-Gas and Anhydrous Ammonia (NH3). These valves are frequently used on...

Open the catalog to page 7

RegulaToRs QuicK selecTion guide MAXIMUM INLET PRESSURE 250 psig / 17.2 bar OUTLET PRESSURE RANGE TYPE NUMBER COMMERCIAL/ INDUSTRIAL HIGH-PRESSURE REGULATORS 7 inches w.c. to 65 psig / 17 mbar to 4.5 bar *See capacity tables in the following sections for expanded rating information. 1. Based on inlet pressure 20 psig / 1.4 bar greater than outlet with 20% droop, unless otherwise noted. 2. Based on 2000 psig / 138 bar inlet pressure setting.

Open the catalog to page 8

RegulaToRs QuicK selecTion guide MAXIMUM INLET PRESSURE 125 psig / 8.6 bar OUTLET PRESSURE RANGE TYPE NUMBER 3.5 inches w.c. to 2 psig / 9 mbar to 0.14 bar 3.5 inches w.c. to 5.5 psig / 9 mbar to 0.38 bar COMMERCIAL/ INDUSTRIAL LOW-PRESSURE REGULATORS 8 inches w.c to 5.5 psig / 20 mbar to 0.38 bar 9 inches w.c. to 16 psig / 22 mbar to 1.1 bar 7 inches w.c. to 5 psig / 18 mbar to 0.35 bar 3 inches w.c. to 5 psig / 7 mbar to 0.35 bar 63.25M BTU per hour/ 712 SCMH 556,000 BTU per hour / 6.2 SCMH(4) *See capacity tables in the following sections for expanded rating information. 1. Based on...

Open the catalog to page 9

RegulaToRs QuicK selecTion guide MAXIMUM INLET PRESSURE OUTLET PRESSURE SETTING/SETPOINTS TYPE NUMBER 10 psig / 0.69 bar +/- 1 psig / 69 mbar nominal outlet setting (non-adjustable) 5 or 10 psig / 0.35 or 0.69 bar standard setpoints FIRST-STAGE REGULATORS 250 psig / 17.2 bar MAXIMUM INLET PRESSURE 10 psig / 0.69 bar STANDARD SETPOINT TYPE NUMBER Type HSRL *See capacity tables in the following sections for expanded rating information. 1. Based on 30 psig / 2.1 bar inlet pressure and 20% droop. 2. Based on 10 psig / 0.69 bar inlet pressure setting. 3. Second-Stage regulators are UL® rated.

Open the catalog to page 10

RegulaToRs QuicK selecTion guide MAXIMUM INLET PRESSURE STANDARD SETPOINT TYPE NUMBER MAXIMUM INLET PRESSURE STANDARD SETPOINT First-Stage: Approximately 10 psig / 0.69 bar (non-adjustable) TYPE NUMBER Second-Stage: 11 inches w.c. / 27 mbar INTEGRAL TWO-STAGE REGULATORS First-Stage: Approximately 10 psig / 0.69 bar (non-adjustable) Second-Stage: 11 inches w.c. / 27 mbar *See capacity tables in the following sections for expanded rating information. 1. Based on 10 psig / 0.69 bar inlet pressure setting and 20% droop. 2. Based on 30 psig / 2.1 bar inlet pressure setting and 2 inches w.c. / 5...

Open the catalog to page 11

RegulaToRs QuicK selecTion guide MAXIMUM INLET PRESSURE STANDARD SETPOINT First-Stage: Approximately 10 psig / 0.69 bar (non-adjustable) TYPE NUMBER INTEGRAL TWO-PSIG REGULATORS First-Stage: Approximately 10 psig / 0.69 bar (non-adjustable) Second-Stage: 2 psi / 0.14 bar MAXIMUM WORKING PRESSURE RELIEF CAPACITY* TYPE NUMBER BACKPRESSURE REGULATORS/ RELIEF VALVES RELIEF PRESSURE SETTING 100 psig / 6.9 bar 20,000 SCFH / 566 SCMH Propane 12,000 SCFH / 340 SCMH Propane *See capacity tables in the following sections for expanded rating information. 3. Based on 30 psig / 2.1 bar inlet pressure...

Open the catalog to page 12All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages