Catalog excerpts

Product Bulletin Fisherr YD and YS Control Valves Fisher YD and YS three-way cage-guided valves are designed for throttling or flow-switching (on-off) service, and are available in the following constructions: YD (Balanced)–For general converging (flow-mixing) and diverging (flow-splitting) service. Available in standard and high-temperature versions (see figure 1). YS (Unbalanced)–For general converging service. When used in diverging service, recommended for on-off applications only (see figure 1). The Fisher YD and YS product lines are available for a wide range of applications, including sulfide and chloride stress-cracking environments common to the oil and gas production industries. To discuss available constructions, contact your Emerson Process Management sales office and include the applicable codes and standards required for these environments. Economy--Balanced valve plug construction in the YD permits use of smaller, lower-cost actuators. A single one-piece valve accommodates both trim designs and uses Fisher easy-e™ bonnets, gaskets, and packing, thus cutting spare part inventory costs. Application Flexibility--Multipurpose capability results from a valve designed specifically for three-way control. A variety of valve sizes, end connections, port diameters, and trim materials provides design versatility for your control needs. Excellent Sealing Capabilities--The ENVIRO-SEAL™ packing system option is available. This packing system provides excellent sealing, guiding, and loading force transmission. The improved sealing of the ENVIRO-SEAL system can help control emissions to below the EPA (Environmental Protection Agency) limit of 100 ppm (parts per million) from Fisher YD Valve with 667 Actuator valves. The ENVIRO-SEAL packing systems feature PTFE, Graphite ULF, or Duplex packing with live-loading for reduced packing maintenance. Long Trim Life--Hardened trim materials provide excellent wear resistance. Easy Maintenance--Cage-type construction simplifies inspection and removal of parts. Parts Commonality--Packing parts, including packing flange, studs and nuts, and packing kits, are common to the YD, YS, and Fisher easy-e control valves. Valve Plug Stability-- Rugged cage guiding provides high valve plug stability, which reduces vibration and mechanical noise.

Open the catalog to page 1

Product Bulletin Specifications Valve Sizes, Ratings, and End Connections (1,2) Operative Pressure/Temperature Limits(1, 2) Pressure Drop Limit Due to Gasket Loading: See table 1 Shutoff Pressure Drop Limits with Typical Actuators: See tables 6, 7, and 8 Pressures and Temperatures for Trims Only: See figure 7 Temperatures for Body-Trim Combinations: See table 5 Temperatures for All Other Parts: See table 3 Cast Iron Valves Flanged: NPS 1 through 6 CL125 flat-face or 250 raised-face flanges per ASME B16.1 Screwed: NPS 1/2 through 2 consistent with ASME B16.4 Steel and Stainless Steel Valves...

Open the catalog to page 2

Product Bulletin Specifications (continued) Bonnet Styles See table 11 Valve Plug Styles YD: Balanced, metal-seated YS: Unbalanced, metal-seated Construction Materials Rated Travels and Port Diameters Valve Body and Bonnet:J Cast iron (except extension bonnet), J WCC steel, J WC9 chrome moly steel, or J CF8M (316 SST) Trims: See table 2 All Other Parts: See table 3 See table 1 Yoke Boss and Stem Diameters for Actuator Mounting VALVE SIZE, NPS VALVE STEM AND YOKE BOSS DIAMETERS, INCHES Standard Yoke Boss Approximate Shipping Weights Optional Stem Yoke Boss Actuator Sizing Pneumatic: See...

Open the catalog to page 3

Product Bulletin ENVIRO-SEAL Packing System Specifications Applicable Stem Diameters J 9.5 mm (3/8 inches), J 12.7 (1/2), J 19.1 (3/4), andJ 25.4 (1) diameter valve stems Maximum Pressure/Temperature Limits(1) To Meet the EPA Fugitive Emission Standard of 100 PPM(2) For ENVIRO-SEAL PTFE and ENVIRO-SEAL Duplex packing systems: full CL300 up to 232_C (450_F) For ENVIRO-SEAL Graphite ULF packing system: 104 bar (1500 psig) at 316_C (600_F) Construction Materials PTFE Packing Systems Packing Ring and Lower Wiper: PTFE V-ring(3) Male and Female Adaptor Rings: Carbon-filled PTFE V-ring...

Open the catalog to page 4

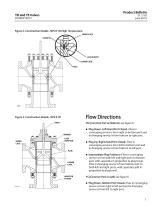

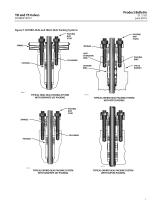

Product Bulletin Figure 2. Construction Details - NPS 8 YD-High Temperature UPPER CAGE GASKETS VALVE BODY LOWER CAGE PLUG Flow Directions Figure 3. Construction Details - NPS 8 YD YD (Common Port on Bottom) see figure 6 Plug Down, Left-Hand Port Closed--Flow in converging service is from right to bottom port and in diverging service is from bottom to right port. Plug Up, Right-Hand Port Closed--Flow in converging service is from left to bottom port and in diverging service is from bottom to left port. Intermediate Plug Positions--Flow in converging service is from both left and right ports...

Open the catalog to page 5

Product Bulletin Plug Up, Right-Hand Port Closed--Flow in converging service is from bottom to left port and in diverging service is from left to bottom port. Intermediate Plug Positions--Flow in converging service is from both bottom and right ports to left port, with capacities in proportion to plug travel. Figure 4. Cutaway of ENVIRO-SEAL Bellows Seal Bonnet and Internal Shroud, Showing Bellows operational life and reliability of these systems also reduce your maintenance costs and downtime. For applications requiring compliance with environmental protection regulations, the unique...

Open the catalog to page 6

Product Bulletin Figure 5. ENVIRO-SEAL and HIGH-SEAL Packing Systems PACKING BOX STUD SPRING PACKING BOX STUDS SPRINGS ANTIEXTRUSION RING PACKING RING FOLLOWER PACKING LANTERN RING VALVE BONNET TYPICAL HIGH-SEAL PACKING SYSTEM WITH GRAPHITE ULF PACKING TYPICAL ENVIRO-SEAL PACKING SYSTEM WITH PTFE PACKING PACKING BOX STUD SPRINGS FOLLOWER PACKING TYPICAL ENVIRO-SEAL PACKING SYSTEM WITH GRAPHITE ULF PACKING TYPICAL ENVIRO-SEAL PACKING SYSTEM WITH DUPLEX PACKING

Open the catalog to page 7

Product Bulletin Table 1. Travel, Port, and Gasket Loading Pressure Drop Information MAXIMUM RATED TRAVEL SEAT RING PORT DIAMETER PRESSURE DROP LIMIT DUE TO GASKET LOADING YS YD(1) 1. For standard YD only. For high temperature YD, consult your Emerson Process Management sales office. 2. NPS 8 only available in YD construction. Table 2. Trim Materials MATERIAL Valve Plug Upper Cage and Lower Cage Upper Cage Retaining Ring (High-Temperature YD Only) Upper Seat Ring (YS Only) and Lower Seat Ring 1. Standard trim for stainless steel valves. Figure 6. Flow Directions

Open the catalog to page 8All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages