Catalog excerpts

Product Bulletin Slurry Vee-Ball Valve Fisher™ Slurry Vee‐Ball™ V150S and V300S Rotary Control Valves The Fisher V150S and V300S Slurry Vee‐Ball valve mates with CL150 and CL300 raised-face flanges. Rugged construction, highly wear‐resistant trim materials, and an unrestricted straight through flow path make the design ideal for controlling the most abrasive of slurries. A shaft with a choice of drive connections will allow a variety of power operated actuators and valve positioners or controllers to be used. X0186-1 The design is particularly effective in minimizing erosive damage to the adjoining pipework, thereby providing greater operational safety and service life when compared with other valve types. Features n Fully protective trim—The valve body, shaft, and bearings are fully protected by hard wear‐resistant trim materials. Fisher Slurry Vee‐Ball Control Valve n Long Service Life—The Vee‐Ball design, when used in reverse flow mode, keeps the high velocity down stream of the vena contracta within the flow ring bore at the outlet of the valve. Compared with other styles of valves, the exit flow is essentially parallel with the flow ring wall and a minimum of flow impingement occurs. Combined with a choice of hard wear‐resistant materials, a significantly long life is obtained. Easily replaceable trim parts allow the valve to be overhauled at predetermined intervals and the valve body used again during repeated operational cycles. n Ease of installation—Full flanging on the valve body n Pipeline and flange protection—The throttled flow stream is guided through a specially shaped flow ring to minimize turbulence and impingement on the pipe wall. The valve can be matched to the bore size of the inlet and outlet piping in order to prevent turbulence being generated by the step resulting in scouring erosion of the flange faces, unexpected leakage, and expensive rework. In addition, both the inlet and outlet valve flange faces are protected by a portion of the hard trim. allows the valve body to be easily aligned centrally with the pipe flanges, an essential requirement in avoiding erosion across the flange faces. n Excellent Flow Control—Precise contouring of the V‐notch ball provides a modified equal percentage flow characteristic. When combined with a valve actuator/controller system having minimal lost motion, improved process control c

Open the catalog to page 1

Product Bulletin 51.3:Slurry Vee-Ball December 2019 Features (continued) n Quick and Easy Maintenance—All trim parts are retained without the use of press fits or screw threads exposed to the process fluid. See figure 1. n Structural Integrity—The valve body, complete with flanges, is made from a one‐piece casting. No welding is employed. No O‐ring seals are used. Use of a flanged valve body does not require the use of extra long studs. The shaft seal is made from well‐proven PTFE chevron ring packing with the means for external adjustment. Options n A PSZ (partially stabilized zirconia)...

Open the catalog to page 2

Product Bulletin Slurry Vee-Ball Valve D103154X012 Specifications Valve Sizes J NPS 3, J 4, J 6, J 8, J 10, and J 12 End Connection V150S: CL150 Raised‐face flange V300S: CL300 Raised‐face flange Face to Face Dimension See figure 2 Maximum Inlet Pressure Consistent with pressure‐temperature ratings per ASME B16.34 but do not exceed the material temperature capabilities shown below or the pressure drop limitations Maximum Shut Off Pressure See tables 3 and 4 Shutoff Classification Class I per ANSI/FCI 70‐2 and IEC 60534‐4 (Class II and better not available). A defined initial maximum leak...

Open the catalog to page 3

Product Bulletin Slurry Vee-Ball Valve Table 1. Standard Construction Materials MATERIAL TEMPERATURE CAPABILITY Part Valve Body Carbon Steel ASME SA216 WCC Body Liner High Chrome Iron (HCI) ASTM A532 Class III Type A High Chrome Iron ASTM A532 Class III Type A Ceramic (optional) High Chrome Iron ASTM A532 Class III Type A HCI with Ceramic Insert (optional) Flow Ring Retainer Carbon Steel ASME SA105 Bearing Shroud High Chrome Iron ASTM A532 Class III Type A Drive Shaft Follower Shaft Shaft Pins PTFE V‐ring Packing Box Ring and Follower Retainer Screws and Clips V‐Notch Ball Flow Ring Table...

Open the catalog to page 4

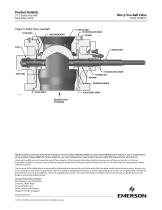

Product Bulletin Slurry Vee-Ball Valve Table 3. V150S and V300S Maximum Allowable Shutoff Pressure Drops (Body Ratings) (Tables for both trim and body limits must be consulted) TEMPERATURE RANGE Table 4. V150S and V300S Maximum Allowable Shutoff Pressure Drops based on Standard Trim. Note: Do not exceed the pressure/temperature rating of the valve or mating flanges TEMPERATURE RANGE Figure 1. Slurry Vee-Ball Cutaway View

Open the catalog to page 5

Product Bulletin Slurry Vee-Ball Valve Table 5. Fisher V150S Dimensions VALVE SIZE 1. Stud length associated with clearance dimension “M” is longer than standard length specified in ASME B16.5. 2. Clearance necessary to remove flange bolts. Figure 2. Slurry Vee-Ball Dimensions (see tables 5 and 6) Table 6. Fisher V300S Dimensions VALVE SIZE 1. Clearance necessary to remove flange bolts.

Open the catalog to page 6

Product Bulletin Slurry Vee-Ball Valve Table 7. Fisher Slurry Vee-Ball Dimensions for Double D Shaft Drive VALVE SIZE FLAT LENGTH FLAT SIZE Figure 3. Fisher Slurry Vee-Ball Dimensions for Double D Shaft Drive (see table 7) W FLAT SIZE 1. This nominal valve shaft diameter is the shaft diameter through the packing box. Use this diameter when selecting Fisher

Open the catalog to page 7

Product Bulletin Slurry Vee-Ball Valve Figure 4. Fisher Slurry Vee-Ball FLOW RING V‐NOTCH BALL FLOW RING RETAINER FOLLOWER SHAFT PLUG DRIVE SHAFT PACKING FOLLOWER PACKING SET BEARING BEARING SHROUD VALVE BODY VALVE BODY LINER REVERSE FLOW STANDARD Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user. Fisher and Vee-Ball are marks owned by one of the companies in the...

Open the catalog to page 8All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages