Catalog excerpts

Product Bulletin Fisherr 4195K Gauge Pressure Indicating Controllers Fisher 4195K gauge pressure indicating controllers show process pressure and set point on an easy‐to‐read process scale. The controllers compare process pressure with an operator‐adjusted set point and delivers a pneumatic signal to a control element so that process pressure changes toward the set point. Controller types are available for proportional‐only, proportional‐plus‐reset, proportional‐plus‐reset‐ plus‐rate, and differential gap for on‐off control. 4195K controllers are used in industries where accurate pressure control and process monitoring are required. Unless otherwise noted, all NACE references are to NACE MR0175-2002. INTERIOR OF A FISHER 4195KBME CONTROLLER W5663‐1 YOKE‐MOUNTED CONTROLLER Notes: 1 An internal cover protects the proportional band adjustment mechanism. In this photograph, the cover has been removed. 2 Controller components are indicated in figure 1.

Open the catalog to page 1

Product Bulletin Specifications Supply Pressure Medium Available Configurations Remote Set Point Pressures Process Sensor Range (Input Signal) Lower and Upper Range Limits: As shown in tables 2 and 5 Maximum Allowable Pressure: As shown in tables 2 and 5 (6 to 30 psig) Construction Materials See table 6 Process Scale Controller Adjustments Standard scale is matched to the range of the sensing element, with exception of receiver controllers. Optional scales available(1). Proportional Band: 5 to 500% of process scale span Reset: Adjustable from 0.01 to more than 74 minutes per repeat (from...

Open the catalog to page 2

Product Bulletin Specifications (continued) Exhaust Capacity(4) 0.2 to 1.0 Bar (3 to 15 Psig) Output: 5.0 m3/hr (186 scfh) 0.4 to 2.0 Bar (6 to 30 Psig) Output: 7.9 m3/hr (295 scfh) Operative Ambient Temperature Limits(2)(6) -40 to 71_C (−40 to 160_F) Designed to NEMA 3 (Weatherproof) and IEC 529 IP54 Specifications Hazardous Area Classification Complies with the requirements of ATEX Group II Category 2 Gas and Dust Controller can be mounted on J actuator, J panel, J wall, or J pipestand Approximate Weight 4.5 kg (10 pounds) NOTE: Specialized instrument terms are defined in ANSI/ISA...

Open the catalog to page 3

Product Bulletin 34.5:4195K July 2014 Features n Easy Maintenance—Simple design allows fast, easy maintenance and minimal spare parts inventory. Construction Features Simplified Relay Maintenance A clean‐out wire provides a fast, easy means of cleaning the relay primary orifice during service. n Easy Adjustment—Adjusting the set point, the zero and span of the process pointer, and switching between direct and reverse action are accomplished quickly and without special tools. Additionally, the set point and proportional band can be adjusted with no interaction between the two adjustments....

Open the catalog to page 4

Product Bulletin Table 2. Process Sensor (Capsular Element) Pressure Ratings CAPSULE MATERIAL CAPSULAR STANDARD RANGES Positive pressure Metric units Compound N09902 Nickel Alloy Positive pressure 0 to 150 mbar 0 to 400 mbar 0 to 0.6 bar 0.2 to 1 bar 0 to 1 bar 0 to 1.4 bar 0 to 1.6 bar 0.4 to 2 bar 0 to 2 bar -150 to 0 mbar -340 to 0 mbar -400 to 0 mbar -0.6 to 0 bar -1 to 0 bar -50 to 100 mbar -175 to 175 mbar -150 to 250 mbar -0.2 to 0.4 bar -0.4 to 0.6 bar -0.6 to 0.8 bar -1 to 0.6 bar -1 to 1 bar 0 to 60 inch wc 0 to 5 psig 0 to 10 psig 3 to 15 psig 0 to 15 psig 0 to 20 psig 6 to 30...

Open the catalog to page 5

Product Bulletin Table 5. Process Sensor (Bourdon Tube) Pressure Ratings and Materials BOURDON TUBES STANDARD MATERIAL Metric units Standard Material 1. Minimum or maximum span or any span in between may be positioned anywhere within the operating range. For example, if a 0 to 2 bar (0 to 30 psig) sensing element is used and the minimum span of 1 bar (15 psig) is set, the process indication can be calibrated to a range of 1 to 0 bar (30 in. Hg to 0 psig), 0 to 1 bar (0 to 15 psig), 1 to 2 bar (15 to 30 psig), 2 to 3 bar (27 to 42 psig) or any value between minimum and maximum values of...

Open the catalog to page 6

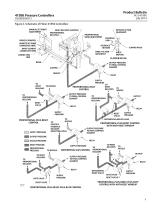

Product Bulletin D200050X012 Figure 1. Controller Construction Details METAL BALL SWITCHING ZONE INDICATOR LOADER KNOB AUTO/MANUAL SWITCH W3679 AUTO/MANUAL STATION SET POINT INDICATOR PROCESS PRESSURE INDICATOR 3 INPUT ELEMENT (BOURDON TUBE) REMOTE SET POINT ASSEMBLY PROPORTIONAL BAND ADJUSTMENT 2 ZERO ADJUSTMENT RELAY POINTER SPAN ADJUSTMENT ADJUSTABLE RELIEF VALVE (ANTI‐RESET WINDUP) SUPPLY PRESSURE GAUGE OUTPUT PRESSURE GAUGE SET POINT SPAN ADJUSTMENT INPUT ELEMENT (CAPSULAR ELEMENT) RESET ADJUSTMENT (PROPORTIONAL‐PLUS‐RESET CONTROLLERS ONLY) RATE ADJUSTMENT RESET ADJUSTMENT FOR...

Open the catalog to page 7

Product Bulletin 34.5:4195K July 2014 Principle of Operation Refer to the schematic diagrams in figures 2, 3, and 4. Refer to table 1 for a complete description of type number suffixes. Proportional‐Only Controllers (4195KA) The input element is connected to the process pointer and to the flapper by connecting links. As the process pressure increases (in a direct‐acting controller), the flapper moves toward the nozzle, restricting flow through the nozzle and increasing nozzle pressure. When this occurs, relay action increases the output pressure (delivery) of the controller. Output pressure...

Open the catalog to page 8

Product Bulletin D200050X012 Figure 2. Schematic of Fisher 4195K Controllers MANUAL SET POINT ADJUSTMENT RESET BELLOWS (VENTED) PROPORTIONAL BELLOWS REVERSE ACTION QUADRANT PROPORTIONAL BAND ADJUSTMENT PROCESS POINTER REMOTE SET POINT CONNECTED HERE FEEDBACK LINK FEEDBACK MOTION INPUT ELEMENT CONNECTED HERE FLAPPER PIVOT DIRECT ACTION QUADRANT CONNECTING LINK INPUT MOTION FLAPPER DETAIL BEAM OUTPUT PRESSURE TO FINAL CONTROL ELEMENT FLAPPER NOZZLE RELAY SUPPLY PRESSURE TO TO NOZZLE RESET BELLOWS PROPORTIONAL‐ONLY CONTROL OUTPUT PRESSURE TO FINAL CONTROL ELEMENT TO PROPORTIONAL BELLOWS RESET...

Open the catalog to page 9

Product Bulletin 34.5:4195K July 2014 controller to respond to the change quickly with high gain, but not long enough for the high gain to cause instability. Then, the low gain provided by the proportional action keeps the system stable. Finally, reset action slowly increases the gain and returns the process pressure toward the set point. Differential Gap (For On‐Off Control) Controllers (4195KS) The operation of differential gap controllers (4195KS) is similar to that of proportional‐only controllers (described above). However, in 4195KS controllers, as the process pressure increases,...

Open the catalog to page 10All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages