Catalog excerpts

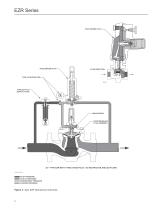

EZR Series Pressure Reducing Regulator Introduction The Type EZR pilot-operated, pressure reducing regulator is designed for natural gas transmission/ distribution systems and industrial/commercial applications. The Type EZR provides smooth, quiet operation, tight shutoff and long life, even in dirty service. Its internally actuated metal plug eliminates disadvantages associated with boot-style regulators and the specially engineered flow path deflects debris, protecting the seat from damage and erosion. The Type EZR is used in conjunction with a 161EB or 161AY Series pilot and Type 112 restrictor or with a PRX Series pilot (with integral restrictor). The Type EZR pressure reducing regulator can be converted to a high pressure relief valve or backpressure regulator by simply changing to a relief piloting system (refer to Bulletin 71.4:EZR). TYPE EZROSX WITH INTEGRAL SLAM-SHUT DEVICE Figure 1. EZR Series Pressure Reducing Regulator An optional inlet strainer prevents large particles from entering the main valve, limiting damage to internal parts. A Type 252 pilot supply filter (optional) can be added to keep pipeline debris from entering the pilot. For underpressure and/or overpressure protection, the Type EZR is available with an integral

Open the catalog to page 1

TRIM PACKAGE TYPE 161EB PILOT MAINTENANCE TYPE EZR PRESSURE REDUCING REGULATOR Figure 2. EZR Series Features and Benefits Tight Shutoff—The EZR Series uses a diaphragm and metal plug, eliminating the disadvantages of bootstyle regulators. When open, the metal plug deflects particles and debris away from the diaphragm. The result is enhanced resistance to particle erosion, which provides excellent shutoff over an extended life. When closed, loading pressure and the main spring push the diaphragm onto the tapered-edged seat on the cage. Debris Protection—The specially engineered flow path,...

Open the catalog to page 2

Long Life—The robust design of the EZR Series with its metal plug and specially engineered flow path allows flow through the regulator without seat impingement. The diaphragm design eliminates the possibility of taking a “set”, a common problem with boot-style regulators. To prevent damage, the diaphragm is fully supported in both the open and closed positions. These features enable the EZR Series components to work longer with less wear and tear. Full Usable Capacity—Fisher™ branded regulators are laboratory tested. 100 percent of the published flow capacity can be used with confidence....

Open the catalog to page 3

Easily Maintained Pilots—The pilots are designed to allow quick and simple in-line trim inspection and parts replacement. Powder Paint Coating—Fisher™ regulators are powder paint coated providing superior impact, abrasion and corrosion resistance. Slam-shut device— Type EZROSX with slamshut device provides either overpressure (OPSO) or overpressure and underpressure (OPSO/UPSO) protection by completely shutting off the flow at the downstream system. Pilot Type Descriptions Type 161AY—Low-pressure pilot with an outlet pressure range from 6 in. w.c. to 7 psig / 15 mbar to 0.48 bar. Pilot...

Open the catalog to page 4

EZR Series Specifications This section lists the specifications for the EZR Series pressure reducing regulator. The set pressure range for a pilot as it comes from the factory appears on the spring case. Other information for an individual main valve appears on the nameplate. Available Configurations Type EZR: Pilot-operated pressure reducing regulator for low to high outlet pressure Type EZROSX: Type EZR with a Type OS2 slamshut device for overpressure (OPSO) or overpressure and underpressure (OPSO/UPSO) protection Main Valve Body Sizes, End Connection Styles and Structural Design...

Open the catalog to page 5

EZR Series Specifications (continued) 161AY Series Pilots (continued) Lever Assembly: Stainless steel Pusher Post: Stainless steel Diaphragm: Nitrile (NBR) or Fluorocarbon (FKM) O-rings: Nitrile (NBR) or Fluorocarbon (FKM) Orifice: Stainless steel Disk Assembly: Nitrile (NBR) or Fluorocarbon (FKM) PRX Series Pilots Body: Steel Trim: Stainless steel Elastomers: Nitrile (NBR) or Fluorocarbon (FKM) Disk Material: Polyurethane (PU) or Fluorocarbon (FKM) Mounting Parts Pilot Mounting Pipe Nipple: Plated steel Tubing and Fittings: Stainless steel Type 112 Restrictor Body: Stainless steel Groove...

Open the catalog to page 6

EZR Series Table 2. Outlet (Control) Pressure Ranges and Typical Proportional Bands (continued) PILOT CONTROL SPRING INFORMATION OUTLET (CONTROL) PRESSURE RANGE Part Number Color Code Wire Diameter Free Length Yellow Green Blue Black Silver Gold Aluminum 1. Proportional band and Accuracy Class include outlet pressure drop plus hysteresis (friction), but do not include lockup. Table 3. Pilot Pressure Ratings MAXIMUM INLET PRESSURE MAXIMUM EMERGENCY OUTLET PRESSURE OR MAXIMUM EMERGENCY SENSE PRESSURE(1) MAXIMUM BLEED (EXHAUST) PRESSURE FOR MONITOR PILOT 1. Maximum pressure to prevent the...

Open the catalog to page 7

FLOW DIRECTION TYPE 252 PILOT SUPPLY FILTER MAIN SPRING DIAPHRAGM AND PLUG ASSEMBLY 3A—TYPE EZR WITH TYPES 161EB PILOT, 112 RESTRICTOR AND 252 FILTER W7438_07/2008 INLET PRESSURE OUTLET PRESSURE ATMOSPHERIC PRESSURE LOADING PRESSURE Figure 3. Type EZR Operational Schematic

Open the catalog to page 8

EZR Series PRX SERIES PILOT TYPE 252 PILOT SUPPLY FILTER MAIN SPRING DIAPHRAGM AND PLUG ASSEMBLY FLOW DIRECTION S - SUPPLY PORT B - BLEED PORT L - LOADING PORT A - SENSING PORT 3B—TYPE EZR WITH PRX SERIES PILOT AND TYPE 252 FILTER SCHEMATIC INLET PRESSURE OUTLET PRESSURE ATMOSPHERIC PRESSURE LOADING PRESSURE Figure 3. Type EZR Operational Schematic (continued) Principle of Operation As long as the outlet (control) pressure is above the outlet pressure setting, the pilot valve plug or disk remains closed (Figure 3). Force from the main spring, in addition to inlet pressure bleeding through...

Open the catalog to page 9

EZR Series ELASTOMER/FABRIC MATERIAL CODE THICKNESS YEAR OF MANUFACTURE CODE RADIAL LOCATION TO LOCATE IMPRINT CODE Table 5. Diaphragm Imprint Codes THICKNESS DIAPHRAGM MATERIAL 17E88 - Fluorocarbon (FKM) (high aromatic hydrocarbon content resistance) 17E97 - Nitrile (NBR) (high-pressure and/or erosion resistance) LOCATE INK CODE BETWEEN RADII MATERIAL INK CODE DOME IDENTIFICATION THICKNESS INK CODE (USE ONE LOCATION ONLY) MANUFACTURER CODE Figure 4. Diaphragm Markings Monitoring Systems Monitoring regulation is overpressure protection by containment, therefore, there is no relief valve to...

Open the catalog to page 10All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages