Catalog excerpts

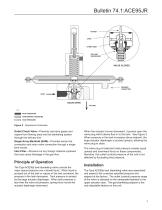

Type ACE95jr Tank Blanketing Valve Features • Stainless Steel Construction Available • Fully Balanced Plug Design Reduces Inlet Pressure Sensitivity • Bubble Tight Shutoff • Vacuum Settings Available Figure 1. Type ACE95jr Tank Blanketing Valve Introduction Type ACE95jr valves are self-contained, fully balanced, and used for accurate pressure control on tank blanketing systems. These valves help control emissions and provide protection against atmospheric contamination. Type ACE95jr valves maintain a positive tank pressure which reduces the possibility of tank wall collapse during pump out operations and prevents a stored product from vaporizing to atmosphere. Tank blanketing is the process of using a gas, usually an inert gas such as nitrogen, to maintain a slightly positive pressure in an enclosed storage tank. Tank blanketing prevents a stored product from vaporizing into the atmosphere, reduces product combustibility, and prevents oxidation or contamination of the product by reducing its exposure to air. Tank blanketing is utilized with various products, including: adhesives, pharmaceuticals, pesticides, fertilizers, fuels, inks, photographic chemicals, and food additives.

Open the catalog to page 1

Bulletin 74.1:ACE95JR Specifications Sizes and End Connection Styles 1/2 NPT 1 x 1/2 NPT 1 NPT NPS 1/2 / DN 15, CL150 RF NPS 1 / DN 25, CL150 RF NPS 1 x 1/2 / DN 25 x 15, CL150 RF NPS 1 / DN 25, Sanitary Flange Maximum Operating Inlet Pressure(1) 200 psig / 13.8 bar Maximum Emergency Outlet (Casing) Pressure(1) 20 psig / 1.4 bar Maximum Operating Control Pressure(1) 1.5 psig / 0.10 bar Control Pressure Ranges(1) See Table 1 Maximum Differential Pressures Up to 200 psig / 13.8 bar Main Valve Flow Characteristic Linear Pressure Registration External Capacities See Table 4 Temperature...

Open the catalog to page 2

O-RING SEAT ROLLING DIAPHRAGM VALVE CLOSED SENSING CONECTION INLET VALVE OPEN TO TANK E0205 INLET PRESSURE ATMOSPHERIC PRESSURE TANK PRESSURE Figure 2. Operational Schematic Outlet Check Valve—Prevents corrosive gases and vapors from flowing back into the blanketing system through the delivery line. Single Array Manifold (SAM)—Provides sense line connection and main valve connection through a single tank nozzle. Inlet Filter—Screens out any foreign material upstream that may cause blockage in the gas flow. Principle of Operation The Type ACE95jr tank blanketing valve controls the vapor...

Open the catalog to page 3

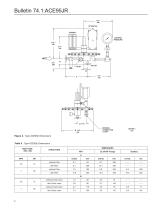

BLANKETING GAS SUPPLY LINE SENSING LINE LINE STRAINER SHUTOFF VALVE TYPE 252 INLET FILTER SHUTOFF VALVE TANK VENT SHUTOFF VALVE EMERGENCY TANK VENT BLANKETING GAS TO TANK BLANKETING GAS/VAPOR SPACE Figure 3. Type ACE95jr Tank Blanketing Valve Installation When installing Type ACE95jr, the sensing line and gasto-tank line must always be above the tank liquid level and should slope down towards the tank without any traps to avoid catching of liquid. Inlet supply line may be installed with a filter and the outlet piping should be full-sized and self draining to the tank and also valves and...

Open the catalog to page 4

Bulletin 74.1:ACE95JR Thermal Equations Capacity Information For tanks up to 840,000 gallons / 3180 m3 capacity: Capacity tables are based on 0.97 specific gravity nitrogen. Nitrogen is the most common blanketing gas. Should you use a different gas, convert the tabular values as follows. For blanketing (pad) gases other than nitrogen, multiply the given nitrogen flow rate by the correction factors in Table 3. For gases of other specific gravities, multiply the given nitrogen flow rate by 0.985, and divide by the square root of the appropriate specific gravity. Equation 1: Qthermal [SCFH...

Open the catalog to page 5

PURGES CONTROL PRESSURE 11.8 / 300 Figure 4. Type ACE95jr Dimensions Table 5. Type ACE95jr Dimensions BODY SIZE, NPS / DN without Filter with Filter without Filter with Filter without Check valve with Check valve without Check valve with Check valve

Open the catalog to page 6

Bulletin 74.1:ACE95JR Ordering Guide Body Size and Connection Styles (Select One) 1/2 NPT 1 x 1/2 NPT 1 NPT NPS 1/2 / DN 15, CL150 RF NPS 1 / DN 25, CL150 RF NPS 1 x 1/2 / DN 25 x 15, CL150 RF NPS 1 / DN 25, Sanitary Flange Actuator/Diaphragm (Select One) Carbon Steel with PTFE Diaphragm Stainless Steel with PTFE Diaphragm Elastomers (Select One) Nitrile (NBR) Fluorocarbon (FKM) Ethylenepropylene (EPDM - FDA) Perfluoroelastomer (FFKM) Accessories (Optional) Inlet Pressure Gauge Control Pressure Gauge Purge Meter (Rotameter) ...

Open the catalog to page 7

Industrial Regulators Emerson Process Management Regulator Technologies, Inc. Emerson Process Management Regulator Technologies, Inc. Emerson Process Management Tescom Corporation Asia-Pacific Singapore 128461, Singapore Tel: +65 6770 8337 Middle East and Africa Dubai, United Arab Emirates Tel: +971 4811 8100 For further information visit www.fisherregulators.com The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC, a business of Emerson Process...

Open the catalog to page 8All FISHER REGULATORS catalogs and technical brochures

-

™ Control Valves and Instruments

16 Pages

-

Run with higher performing,

16 Pages

-

R Series

2 Pages

-

LP-Gas Technologies

118 Pages

-

Industrial Regulators

2 Pages

-

Type 92B Pressure Reducing Valve

16 Pages

-

Type 630R Relief Valve

8 Pages

-

Fisher™ 585C Piston Actuators

16 Pages

-

Type 630 Regulator

16 Pages

-

Fisher™ YD and YS Control Valves

24 Pages

-

easy-e Cryogenic Valves

12 Pages

-

Large ET and ED Valves

20 Pages

-

1305 Series Regulators

4 Pages

-

H200 Series Relief Valves

4 Pages

-

Air Application Map

1 Pages

-

DeltaV Controller Firewall

11 Pages

-

CSI 6500 Overview

12 Pages

-

The Criticality of Cooling

5 Pages

-

Ovation Security Center

4 Pages

-

DeltaV Smart Switches

28 Pages

-

Smartprocess™ Heater

5 Pages

-

FPSO Industry Solution

2 Pages

-

LP-31

96 Pages

-

CS 200 series

2 Pages

-

Regulators Mini Catalog

24 Pages

-

1301F, 1301G

12 Pages

-

MR95 and MR98

2 Pages

-

Fisher® D and DA Valves

12 Pages

-

Fisher® EZ easy-e Control Valve

40 Pages

-

Fisher® YD and YS Control Valves

24 Pages

-

Fisher® HPNS Control Valve

36 Pages

-

Fisher® HP Series Control Valves

28 Pages

-

Fisher® CAV4 Control Valve

28 Pages

-

Fisher® 377 Trip Valve

20 Pages

-

EZR Pressure Reducing Regulator

36 Pages

-

630 Regulator

16 Pages

-

627F Pressure Reducing Regulator

12 Pages

-

ACE97 Pad-Depad Valve

16 Pages

-

310A Pressure Reducing Regulator

16 Pages

-

S200 series

32 Pages

-

R622 series

8 Pages

-

Type HSR Pressure Regulators

20 Pages

-

cs200 series

40 Pages

-

CS400 Series

60 Pages

-

167D Series Switching Valves

8 Pages

Archived catalogs

-

Vapor Pressures of LP-Gas

1 Pages

-

Pipe and Tubing Sizing

1 Pages

-

Average Properties of LP-Gas

1 Pages

-

Pressure Equivalents

1 Pages