Catalog excerpts

The new solution to vibration isolation problems Increase productivity and reduce downtime with Marsh Mellow fabric & rubber springs. Long life, simple mounting, fast replacement time, and virtually maintenancefree operation boost machine availability for greater productivity. Marsh Mellow springs cannot break, trap particles, corrode, or bottom-out. Each spring features a bias-ply fabric wrap for dependability and uniform performance. The variable rate/ constant frequency of the spring allows each spring size to accommodate a wide load range and perform consis- tently, whatever the load. Tough, quiet Marsh Mellow springs are a great new solution to those same old isolation problems. Replace old-fashioned metal springs with fabric and rubber springs for longlasting, low-cost isolation performance. Specify Marsh Mellow springs by Firestone.

Open the catalog to page 1

Firestone Marsh Mellow spring Selection Guide Marsh Mellow spring Maximum Allowable Stroke @ 800 1200 CPM in/mm UNLOADED SIZE Outside Diameter in/mm 15⁄8 Natural Frequency CPM/Hz Compressed Height in/mm Maximum LoadIng lbs/kN MAXIMUM LOADING Natural Frequency CPM/Hz Compressed Height in/mm Minimum Loading lbs/kN Free Height in/mm 13⁄4 Inside Diameter in/mm MINIMUM LOADING

Open the catalog to page 2

Advantages with Marsh Mellow springs ® Constant Vibration isolation with Changing Loads The variable spring rate allows for a nearly constant natural frequency with changing loads. This results in consistent vibration isolation with variable loading. High Load Carrying Capacity Due to the Marsh Mellow® spring’s greater deflection capabilities and load carrying influences of the fabric reinforcement, it can carry a greater load when compared to an all rubber part of the same modulus and dimensions. Excellent Vibration Isolation Low natural frequencies provide excellent isolation of forced...

Open the catalog to page 3

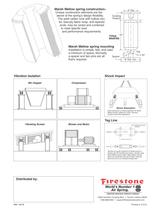

Marsh Mellow spring construction– Unique construction elements are the secret of the spring’s design flexibility. The solid rubber core with hollow center, bias-ply fabric wrap, and tapered ends, may be varied and combined to meet specific load and performance requirements. Marsh Mellow spring mounting Installation is simple, fast, and uses 1” Dia. a minimum of space. Normally, 1/4” x 45° 1 1 /2 ” a spacer and two pins are all Spacer 8” Dia. min. that’s required. Vibration Isolation Bin Hopper Shock Impact Compressor Shock Absorption Shock absorption is a natural application for Marsh...

Open the catalog to page 4All Firestone Industrial catalogs and technical brochures

-

Date Codes Sheet

2 Pages

-

Corporate Brochure

2 Pages

-

Air Spring Maintenance

4 Pages

-

DR Series Flyer DRS_A4

2 Pages

-

Airstroke Airmount brochure

12 Pages

-

Airide Design Guide Design Guide

84 Pages

-

Airail Springs Design Guide Rail

52 Pages

-

Aftermarket LoadShare

28 Pages

-

Aftermarket BUS_014

50 Pages

-

Aftermarket Catalog Mexico MXCAT

251 Pages

-

Airstroke Airmount brochure ASAM

12 Pages

-

Marshmellow Brochure

60 Pages

-

Airstroke/Airmount Brochure

12 Pages