Catalog excerpts

HYDRAULIC FILTRATION F040-DMD series In line medium pressure filters Technical Information Pressure: Max working (acc. to NFPA T 3.10.5.1): F040-DMD0005/8/11: 70 bar (1015 psi) F040-DMD0015/30/45: 40 bar (580 psi) Test (acc. to NFPA T 3.10.5.1): F040-DMD0005/8/11: 140 bar (2030 psi) F040-DMD0015/30/45: 80 bar (1160 psi) Burst (acc. to NFPA T 3.10.5.1): F040-DMD0005/8/11: 210 bar (3000 psi) F040-DMD0015/30/45: 120 bar (1740 psi) Connection Ports: 3/4” – 1 1/4” BSP (other thread options on request) Materials: Head: Bowl: Seal: aluminium alloy aluminium alloy NBR (FKM on request) Filter Media: Microglass fiber Differential collapse pressure: 30 bar (305 psi) (acc. to ISO 2941) The Filtrec elements are tested also according to ISO 2942 and ISO 23181 Working temperature: -25°C +120°C (-13°F +248°F) Fluid compatibility (acc. to ISO 2943): Full with HH-HL-HM-HV (acc. to ISO 6743/4). For use with other fluid applications please contact Filtrec Customer Service (info@filtrec.it).

Open the catalog to page 1

Ordering information Filter assembly no element microglass fiber ß4,5 µm ( ) >1000 microglass fiber ß7 µm ( ) >1000 microglass fiber ß12 µm ( ) >1000 microglass fiber ß18 µm ( ) >1000 microglass fiber ß27 µm ( ) >1000 cellulose ß10 µm ( ) >2 cellulose ß20 µm ( ) >2 C NOMINAL SIZE INDICATOR PORT OPTION NPT option available on request, please check availability with Filtrec Customer Service. INDICATOR PORT OPTION without (on request*) indicator port side with plug *Please contact Filtrec Customer Service TO BE USED WITH NO BY-PASS OPTION ONLY without indicator differential visual 2,7 bar/ 40...

Open the catalog to page 2

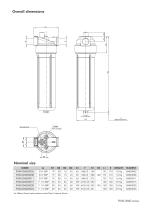

Overall dimensions Indicator port For different thread options please contact Filtrec Customer Service.

Open the catalog to page 3

Pressure Drop diagrams The total Pressure Drop (Dp) value is obtained by adding the Dp values of filter housing and filter element at the given flow rate. This ideally should not exceed 0,5 bar (7 psi) and should never exceed 1/3 of the set value of the by-pass valve. Housing F040-0005-0008-0011 PRESSURE DROP THROUGH THE FILTER HOUSING The Pressure Drop through the filter housing is governed by the port, not the bowl length and the oil viscosity. Flow rate (l/min) PRESSURE DROP THROUGH THE CLEAN FILTER ELEMENT The Pressure Drop through the filter element is related both to the internal...

Open the catalog to page 4

Pressure Drop diagrams The total Pressure Drop (Dp) value is obtained by adding the Dp values of filter housing and filter element at the given flow rate. This ideally should not exceed 0,5 bar (7 psi) and should never exceed 1/3 of the set value of the by-pass valve. Housing F040-0015-0030-0045 PRESSURE DROP THROUGH THE FILTER HOUSING The Pressure Drop through the filter housing is governed by the port, not the bowl length and the oil viscosity. Flow rate (l/min) PRESSURE DROP THROUGH THE CLEAN FILTER ELEMENT The Pressure Drop through the filter element is related both to the internal...

Open the catalog to page 5

Clogging indicator The Pressure Drop (Dp) through the filter increases during the system operation due to the contaminant retained by the filter element. The filter element must be replaced when the indicator shows an alarm and before the Dp reaches the by-pass value setting. N.B. in cold start conditions a false alarm can be caused by higher oil viscosity due to low temperature; the indicator alarm must be considered at normal working temperature only. The differential clogging indicator registers the pressure upstream and downstream the filter element and activates a signal when the...

Open the catalog to page 6

User Tips INDICATOR PORT: Visual Electric SPARE SEAL KIT PART NUMBER NBR FKM F040-DMD0005/8/11 06.021.00127 06.021.00128 F040-DMD0015/30/45 06.021.00129 06.021.00130 FIXING HOLES BY-PASS VALVE IDENTIFICATION LABEL FILTER HEAD BOWL TIGHTENING TORQUE F040-DMD0005/8/11 40 Nm F040-DMD0015/30/45 60 Nm INDICATOR TIGHTENING TORQUE Z30/Z31/Z37/Z38 90 Nm FILTER ELEMENT FILTER BOWL Make sure that the filter is connected in the correct IN-OUT flow direction (shown by an arrow on the filter head). The filter housing should be preferably mounted with the bowl downward; the filter head should be properly...

Open the catalog to page 7

w w w. f i l t r e c . c o m Technical information may change without notice

Open the catalog to page 8All FILTREC S.p.A. catalogs and technical brochures

-

FS-1

4 Pages

-

F100-XD

8 Pages

-

F160-XD

8 Pages

-

F280-D1

8 Pages

-

FD-3

7 Pages

-

FDM-1

8 Pages

-

F420-D1

11 Pages

-

IFBW

12 Pages

-

IFD-RHR

12 Pages

-

IFD-R9

12 Pages

-

IFD-R4

12 Pages

-

IFS-RHR

12 Pages

-

IFS-R9

12 Pages

-

IFS-R4

12 Pages

-

GAS AND AIR

2 Pages

-

PCS

4 Pages

-

PPP

8 Pages

-

PMA

8 Pages

-

PCH

4 Pages

-

PCP

8 Pages

-

PBA

8 Pages

-

BOLL & KIRCH

2 Pages

-

INDICATORS

16 Pages

-

FT

8 Pages

-

FL

4 Pages

-

FB-1

4 Pages

-

FVR-7

8 Pages

-

FS-7

8 Pages

-

FR-8

8 Pages

-

FR-1

12 Pages

-

FCR-7

12 Pages

-

FA-4

8 Pages

-

FA-2

8 Pages

-

FA-1

8 Pages

-

CP-CL SERIES

4 Pages

-

WATER ABSORBENT

4 Pages

-

CORELESS

4 Pages