Catalog excerpts

Multipulse - Medium Capacity Positive Displacement Flowmeters The Multipulse range of positive displacement flowmeters offer a high level of accuracy and repeatability. These precision meters are used for flowrate measurement in flow monitoring and control applications and for totalising in dispensing and batching. Multipulse meters are suitable for use with a wide range of clean liquids including viscous lubricants, chemicals, food bases and non-conductive low viscosity solvents either pumped or gravity fed. F E ATU R E S / B E N E F I TS • • • • • • Flows: 0.2~350 litres/min ( 0.05~90 US gal/min ) Sizes: 15, 25, 40 & 50mm ( 1/2”, 1”, 11/2” & 2” ) connections* High accuracy & repeatability, direct reading flowmeter No requirement for flow conditioning ( straight pipe runs etc ) Intrinsically safe & explosionproof models available Quadrature pulse output option & bi-directional flow * see also Micropulse & Maxipulse data sheets for other size meters & flow ranges M E T E R S E L E C TI O N Meters are selected based on flow range, pressure, temperature, material compatibility and functionality. • Aluminum Multipulse meters are ideal for petroleum products including oils and grease, fuels and fuel oils. Stainless steel meters are suited for chemicals, water based products and the food, cosmetic and pharmaceutical industries. Multipulse meters are available as blind meters with pulse output or with integral or remote totalisers, flow rate displays or preset batch controllers. Pulse meter outputs can be interfaced to most electronic displays or instrumentation. A P P L I C ATI O N S I N C LU D E chemicals, additives, resins, acids, alcohols, essences, edible oils, flavourings, food bases, perfumes, adhesives, emulsions, insecticide, paints, inks, oils, fuels, grease, solvents, lubricants. TRIMEC INDUSTRIES 1/19 Northumberland Road, Caringbah NSW 2229 PO Box 2444 Taren Point NSW 2229 Sydney Australia Ph: +61 2 9540 4433 Fax: +61 2 9525 9411 email: sales@trimecind.

Open the catalog to page 1

Body material Piston material Model prefix: ** Within nominal spans of MP015 (0.17~1.7, 1.7~5 & 5~10 litres/min ) # Maximum thermal shock 10°C (50°F) / min. applies to the reed switch Ertalyte - std. in alum. MP meters - 120°C (250°F) max. PEEK - std. in SS MP meters - 150°C (300°F) max.) CFT - 120°C max. (250°F) Special - eg. 200°C (400°F) Partition material Ceramic (for abrasive liquids) 316 Stainless Steel (standard) O-ring material Viton (standard) -15~+200°C (-5~+400°F) Ethylene Propylene Rubber -150°C (300°F) max. Teflon encapsulated viton -150°C (300°F) max. Buna-N (Nitrile)...

Open the catalog to page 2All Filton Process Control Engineering catalogs and technical brochures

-

Turbopulse Industrial Series

4 Pages

-

SERIES 1200

4 Pages

-

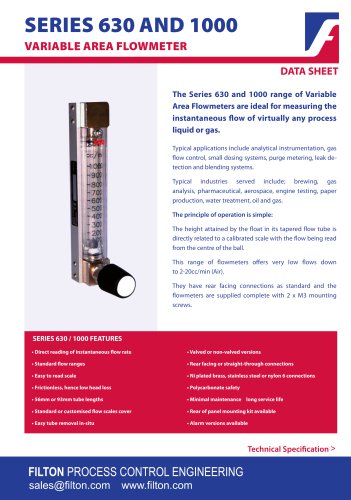

SERIES 630 AND 1000

2 Pages