Catalog excerpts

Splash-proof Terminal HEPA Filter Type GTS Overview The Splash-proofed Terminal HEPA Filter GTS is designed and tested to extract a ‘Minipleat -Media Pack,’ available in different heights, with a new application technology of ‘Hot melt spacers’ to get the lowest pressure drop results. FEATURES • Special Splash proofed stainless steel screen • Efficiencies of 98% up to 99.99995% (@ 0.3 μm) • High quality fibre glass paper • Lowest initial pressure drop • Adjustable airflow by means of a damper Finedust - HEPA / ULPA FILT-AIR LTD. Fine Dust Filter Final Filter for Fan Filter Units Final Filter for Clean Rooms Final Filter for Channel Installation Highly Active Filter Surface - Low Pressure Drop Final Filter for Grid Systems

Open the catalog to page 1

FEATURES: • Anodized rigid aluminium frame • High quality standard due to Quality Assurance System • Tested by laser particle counting system • Highly economical through high final pressure drop • For use in clean rooms up to class 1 Design The housing is made from anodized extruded aluminium profile with two galvanized angles in each corner to create a rigid, straight frame. The alu-zinc hood, with an attached collar, is tide glued on top of the filter. The damper and the aerosol / pressure drop checking inlet is placed in a special middle bridge and is adjustable from downstream. The...

Open the catalog to page 2

APPLICABLE STANDARDS: Testing with European standard BS EN 779 (Particulate air filters for general ventilation). This standard is based on Ashrae 52.76 (Gravimetric and Dust-Spot Procedures for Testing Air Cleaning Devices Used in General Ventilation for Removing Particulate Matter 1992). XY - Scan Testing Device The XY-scan testing device is able to perform automated filter leak testing of high efficiency air filters using automatic particle counters and a motorized scan table. While the particle counter probe passes over the filter face, the computer compares the counted particles with...

Open the catalog to page 3

Dimensional Drawing

Open the catalog to page 4

addition, for DOP efficiency testing (of installed filters), an aerosol entry is provided to allow for easy channelling of the test aerosol to the upstream side of the filter media. Both are covered with a sealed screw to prevent any leaks. Finedust - HEPA / ULPA Version A of the damper system is a combination of an in-room adjustable damper with an aerosol inlet for efficient checking of the installed filter. This feature allows for easy adjustment of the airflow (filter velocity) during checking with a velocity meter from the clean room side. In

Open the catalog to page 5

Technical Data Filter Data Rated face velocity Media pack Initial pressure drop @ rated airflow Filter class as per EN 1822 Initial efficiency @ rated airflow Test with MPPS (integral) Test with aerosol Ø 0.3 μm Filter class as per DIN 24184 Recommended final pressure drop Flammability classification to DIN 53438 Max. relative humidity Filter Sizes Filter Size Rated Airflow

Open the catalog to page 6

Initial Pressure Drop for ‘Minipleat-Media Pack’ in 47 mm Height p [Pa] 225 Initial Pressure Drop for ‘Minipleat-Media Pack’ in 56 mm Height Finedust - HEPA / ULPA

Open the catalog to page 7

Order Numbers Order no. Damper & Collar Screen Material Exp. Steel / Powder Coated Other dimensions available upon request Specifications are subject to change without prior notice HEPA & ULPA Filters for Industrial Clean Rooms FILT AIR Ltd. specializes in the use of advanced technologies to implement a purified air supply for high-tech industry clean rooms, the microelectronics business sectors, and pharmaceutical industries. FILT AIR Ltd. has a broad range of client groups, such as hospitals, industrial plants, commercial buildings, and companies requiring clean air inside gas turbines....

Open the catalog to page 8All FILT AIR catalogs and technical brochures

-

Bipolar Ionization

2 Pages

-

Filt Air’s

8 Pages

-

Safe Change Housing Type H0

4 Pages

-

GH – High Temperature Filter

2 Pages

-

Gas Absorption Filters CP

4 Pages

-

GRV Conical Filters

4 Pages

-

Cylindrical Filter GR0

4 Pages

-

HT Terminal Filters

8 Pages

-

Panel Filter GP

8 Pages

-

Compact Filter GV8 (H10-H14)

4 Pages

-

Compact Filter GW

8 Pages

-

Compact Filter GV8 (F6 – F9)

4 Pages

-

Compact Carbon Filter CV8

4 Pages

-

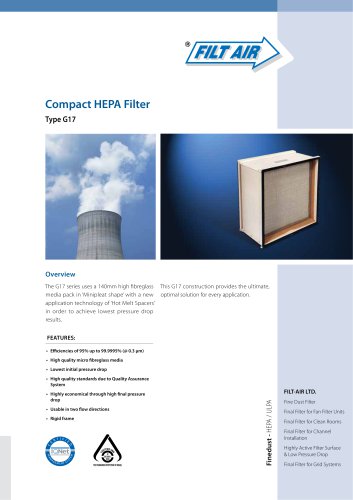

Compact HEPA Filter Type G17

4 Pages

-

Type G09

4 Pages

-

Type CV8 full plastic frame

4 Pages

-

Finedust Filter Type G90

4 Pages

-

GT Terminal Filters

8 Pages

-

GRV Conical Finedust Filters

4 Pages

-

Finedust Filter G90

4 Pages

-

Bag Filter G80

2 Pages

-

Compact filter G7

8 Pages

-

Type GRO

4 Pages

-

Type HT

6 Pages

-

Type GP

8 Pages

-

Type GW

6 Pages

-

Type GVA

4 Pages