Catalog excerpts

APPLICATION: Pre-Sterilized Containers Filling Equipment Pre-sterilized containers can be filled with the automatic Monobloc Fill/Finish Packaging system while keeping the containers sterile throught the process. The primary functions for this machine include: • Removing the screw thread caps from the incoming containers • Filling the containers utilizing peristaltic pump technology • Reapplying the screw thread caps onto the containers The containers are carried in groups of three, through the cap removing, multi-step filling, cap replacing, and cap tightening functions. The completed containers are then pushed from the linear indexing system onto the discharge conveyor. Challenge A challenge for this application was moving the cap along with the container so that it can be recapped on the original container after the filling process was completed. Solution A three pocket cap boat moves parallel to the three indexed containers along the filling proceess. This simple cap boat conveyor transfer system provides a cost effective and simple way to move the caps from the cap removal chucks to the cap prestart chucks, providing the container with its original cap. Industry - Biotech Container -Nalgene Bottles Speed - 60 cpm Metering System - Peristaltic Pump Combination - 4 precapped container sizes/styles Uncapping, Filling, & Recapping Pre-Sterilzed Containers Eliminating the need for washing/sterlizing at the beginning of the filling process Using the pre-sterilized and capped containers and Filamatic's Monobloc Fill/Finish packaging system, eliminates the need for washing/sterilizing at the beginning of the filling process. The bottles are kept sterile since the caps remain on the bottle until it enters the controlled HEPA-filtered environment or clean room. The pre-capped, sterile containers are brought to the filling suite and fed into the filling and capping machine. Filamatic’s linear and turret based Monobloc index the containers to an uncapping station where uncapped and then filled. The cap is then replaced and secured onto the container. FilamaƟc • A Division of NaƟonal Instrument, LLC. • 4119 Fordleigh Road • BalƟmore, MD 21215 1.866.258.1914 • info@lamaƟc.com • www.lamaƟc.com

Open the catalog to page 1All Filamatic catalogs and technical brochures

-

DFS Filler Flow Meter

2 Pages

-

MONOBLOC

4 Pages

-

Automatic Synchromat

2 Pages

-

FUS - FKS FILLING UNITS

2 Pages

-

Piston Filling Units

2 Pages

-

Unscrambler

1 Pages

-

Model IFC-15*

4 Pages

-

DFS Digifil? Filling Systems

2 Pages

-

Line Integration

2 Pages

-

FSV Piston Filling Unit

1 Pages

-

FUS Piston Filling Unit

1 Pages

-

KYU Piston Filling Unit

1 Pages

-

Cubitainer

5 Pages

-

CE-MNB-2000

4 Pages

-

Belt Wheel Capper

2 Pages

-

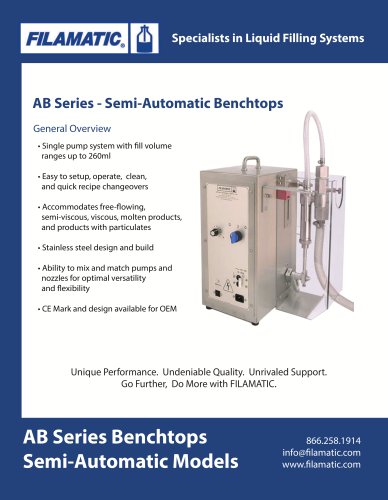

AB Series

2 Pages

-

Monobloc Family Brochure

2 Pages

-

Service Agreement

1 Pages

-

Servo Chuck Capper

2 Pages

-

Accumulators

1 Pages

-

DFS Flow Meter Filler

2 Pages

-

H-CE Molten Filler

2 Pages

-

DFS Lobe Pump Filler

2 Pages

-

DFS Piston Pump Filler

2 Pages

-

Filamatic Synchromat

2 Pages

-

Monobloc Fill/Finish System

2 Pages

Archived catalogs

-

Nozzles

2 Pages

-

In Line Family Brochure

2 Pages

-

Benchtop Family Brochure

2 Pages

-

Automatic Level Filler

2 Pages