Catalog excerpts

Individually fills combination packages ■CubitSjuer1 a s Trademark oi U* Hsdynn C<iriwr*tt5i--, flafoinora. Maraud

Open the catalog to page 1

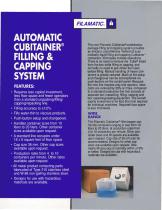

* Requires less capital investment, less floor space and fewer operators than a standard unpacking/filling/ capping/repacking line. • Fills water-thin to viscous products. • Push-button setup and changeover. - Handles container sizes from 10 liters to 20 liters. Other container sizes available upon request. * A standard line occupies under 18x8 square feet of floor space. ■ Cap size 38 rnm. Other cap sizes available upon request. * Production rates from 4 to 10 containers per minute. Other rates available upon request. ■ All metal product contacting parts fabricated of Type 316 stainless...

Open the catalog to page 2

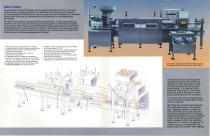

The pre-boxed Cubitainer is placed on the infeed of the Filamatic conveyor. The neck of the container is positioned between the neck locate rails. The conveyor transports the boxed container to the filling area, where sensors check for the presence of a container. Sensors also make sure that containers have not backed up from the capping area The neck of the container is grasped with a horizontal locator. A filling nozzie descends into the mouth of the container, and the liquid is discharged at a moderate rate of speed. If the container has not been pre-inflated during the boxing process,...

Open the catalog to page 3

The filler handles container sizes from 10 to 20 liters, at production rates from 4 to 10 containers At the capping area, a gripper mechanism centers the neck of the bottle, then a pick and place mechanism presents, places The Filamatic filling/capping system is easy to use, even by inexperienced personnel. The operator simply feeds the Cubitainer® units onto the conveyor infeed, and positions the neck of the plastic container in the guide rails. The pre-boxed containers are filled and capped automatically, then are discharged directly into the case sealing machine of your choice. Most...

Open the catalog to page 4

(S:de view horn nl«d and of conveyor) Production Rate: Container Range: Fill Accuracy: Metal Product Contacting Paris: 4 to 10 containers per minute. (Other rates to order.) 10 liter to 20 liter (Other sizes to order.) 38 mm (Other sizes to order.) Type 316 stainless steel and W-88 non-galling stainless steel All dimensions shown are for reference only. Other configurations to order. l34do iivi uom disctiafce wdol cwivtjw) Free Testing Service We will be happy to test run your product to determine the Filamatic model best suited for your needs. There is no cost or obligation for this...

Open the catalog to page 5All Filamatic catalogs and technical brochures

-

DFS Filler Flow Meter

2 Pages

-

MONOBLOC

4 Pages

-

Automatic Synchromat

2 Pages

-

FUS - FKS FILLING UNITS

2 Pages

-

Piston Filling Units

2 Pages

-

Unscrambler

1 Pages

-

Model IFC-15*

4 Pages

-

DFS Digifil? Filling Systems

2 Pages

-

Line Integration

2 Pages

-

FSV Piston Filling Unit

1 Pages

-

FUS Piston Filling Unit

1 Pages

-

KYU Piston Filling Unit

1 Pages

-

CE-MNB-2000

4 Pages

-

Belt Wheel Capper

2 Pages

-

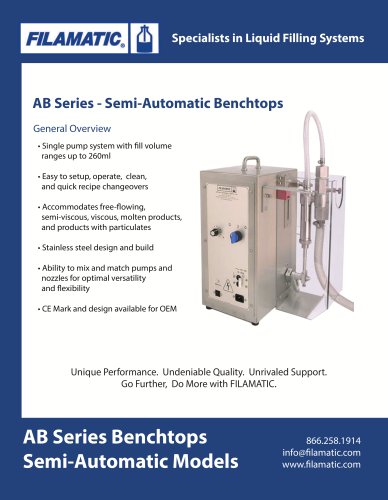

AB Series

2 Pages

-

Monobloc Family Brochure

2 Pages

-

Service Agreement

1 Pages

-

Servo Chuck Capper

2 Pages

-

Accumulators

1 Pages

-

DFS Flow Meter Filler

2 Pages

-

H-CE Molten Filler

2 Pages

-

DFS Lobe Pump Filler

2 Pages

-

DFS Piston Pump Filler

2 Pages

-

Filamatic Synchromat

2 Pages

-

Monobloc Fill/Finish System

2 Pages

Archived catalogs

-

Nozzles

2 Pages

-

In Line Family Brochure

2 Pages

-

Benchtop Family Brochure

2 Pages

-

Automatic Level Filler

2 Pages