Catalog excerpts

APPLICATION: Fill, Check Weigh, Cap Filling Equipment The 100% check weighing capabilty is an additional feature that can be added to the automatic Monobloc Fill/Finish Packaging system. This filling machine includes the following capabilities: • Feeding the containers from a bulk unscrambler • Tare weighing each empty container • Filling the containers utilizing peristaltic pump technology • Gross weighing each filled container and calculating the net weight of the liquid • Applying push-on caps to the containers • Applying labels to the containers • Rejecting improperly filled and assembled containers • Transferring the filled/capped/labeled containers into the carton loading system • Real-time onscreen reporting • Automatic data collection to Excel, SQL database, etc. Challenge The challenge for this application was to properly weigh and 100% verify the fill volume in an unstable container while providing a production rate of 50cpm. Solution Filamatic’s solution was to secure the container in a turret pocket which supports the container throughout the filling, capping, and labeling processes. During the tare and gross weighing processes, the turret disengages from the container, leaving the container untouched as its weight is determined. This process allows for faster weight calculations and higher production rates. Industry - Diagnostic Container -Microtube/Microvial Speed - 50 cpm Metering System - Peristaltic Pump Combination - 2 container sizes/styles, push cap, label, carton Check Weighing 100% Verification - a final check of the product with the data and statistics to prove it The check weigh system incorporates two weigh cells beneath the turret indexing assembly. One weigh cell weighs the empty container and the other weighs the filled container. The empty containers are indexed onto the first weigh cell, and the actuated turret assembly disengages from the container. While the container remains free from contact with the turret, its tare weight is determined. The container is then filled and indexed to the second weigh cell where its gross weight is determined. The net weight is then calculated, recorded, and compared to the pre-programed range. Any container with a fill weight outside the range is collected by the reject system. FilamaƟc • A Division of NaƟonal Instrument, LLC. • 4119 Fordleigh Road • BalƟmore, MD 21215 1.866.258.1914 • info@lamaƟc.com • www.lamaƟc.com

Open the catalog to page 1All Filamatic catalogs and technical brochures

-

DFS Filler Flow Meter

2 Pages

-

MONOBLOC

4 Pages

-

Automatic Synchromat

2 Pages

-

FUS - FKS FILLING UNITS

2 Pages

-

Piston Filling Units

2 Pages

-

Unscrambler

1 Pages

-

Model IFC-15*

4 Pages

-

DFS Digifil? Filling Systems

2 Pages

-

Line Integration

2 Pages

-

FSV Piston Filling Unit

1 Pages

-

FUS Piston Filling Unit

1 Pages

-

KYU Piston Filling Unit

1 Pages

-

Cubitainer

5 Pages

-

CE-MNB-2000

4 Pages

-

Belt Wheel Capper

2 Pages

-

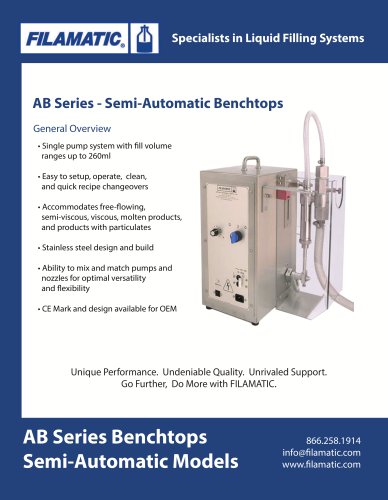

AB Series

2 Pages

-

Monobloc Family Brochure

2 Pages

-

Service Agreement

1 Pages

-

Servo Chuck Capper

2 Pages

-

Accumulators

1 Pages

-

DFS Flow Meter Filler

2 Pages

-

H-CE Molten Filler

2 Pages

-

DFS Lobe Pump Filler

2 Pages

-

DFS Piston Pump Filler

2 Pages

-

Filamatic Synchromat

2 Pages

-

Monobloc Fill/Finish System

2 Pages

Archived catalogs

-

Nozzles

2 Pages

-

In Line Family Brochure

2 Pages

-

Benchtop Family Brochure

2 Pages

-

Automatic Level Filler

2 Pages