Catalog excerpts

ADAPTAFIL™ Semi-Automatic Benchtop FAQ Sheet Filamatic A Division of National Instrument, LLC 4119 Fordleigh Road Baltimore, MD 21215 Why did Filamatic make the AdaptaFil™ Semi-Automatic Benchtop? We asked our customers, past and present, what frustrated them the most about their current Benchtop machines. We listened to their responses and our Engineering team set out to design the ―ideal‖ Benchtop. They incorporated several features typically only found on fully automated machines and found a way to provide four interchangeable pumps on the same base. This saves the customers time, money, and space. The end result is the most versatile Semi-Automatic Benchtop in the industry. What are the benefits to having four different interchangeable pumps on one base and what products can each pump fill? The number one benefit is the ultimate flexibility provided in regard to products, fill ranges, and fill rates. Having four interchangeable pumps available for one base also eliminates the need to buy a new machine for every pump—all with just a quick tool-less changeover. The four interchangeable pumps are Peristaltic, Gear, Lobe, and Piston. The products they can fill are: Your Specialist in Liquid Filling Equipment and Integrated Systems Peristaltic – free flowing (water like products) Gear – free flowing, semi-viscous, viscous, and product with medium particulates Lobe –free flowing, semi-viscous, viscous, and product with large particulates Piston –free flowing, semi-viscous, viscous, product with small particulates and precise fills Why is it called a Benchtop? Benchtop, also called Tabletops, are named for their size. They are meant to fit on a table or small space and are ideal for upstart companies, R & D departments, small production runs, and budget conscious projects. Can you automate the AdaptaFil™ and are they expandable? The AdaptaFil™ can be automated and has a modular design with built-in controls for multiple units. If your production changes, the AdaptaFil™ is prepared to accommodate your needs. Contact Us: 1.866.258.1914 info@filamatic.com www.filamatic.com Human-Machine Interface. It’s an intuitive touch screen that provides you with the same capabilities as our automatic filling machines. You have the ability to create, save, and copy 100+ recipes by name, print, and transfer data. How big is the AdaptaFil™ and where is it manufactured? Our smallest and most compact liquid filling machine, the AdaptaFil™ dimensions are 16.6 in x 12 in. Filamatic is a privately held, family-owned operation located in Baltimore, MD. All of our machines are designed and manufactured in the U.S.A. How long has Filamatic been in business and what industries do they serve? Filamatic has been manufacturing liquid filling equipment for over 50 years. Servicing the pharmaceutical, biotech, diagnostic, healthcare, specialty chemical and food industries, we provide a wide range of equipment that can be customized to suit your unique application and/or budget. Each unit is specially manufactured to provide increased throughput and faster changeover while reducing downtime and increasing overa

Open the catalog to page 1All Filamatic catalogs and technical brochures

-

DFS Filler Flow Meter

2 Pages

-

MONOBLOC

4 Pages

-

Automatic Synchromat

2 Pages

-

FUS - FKS FILLING UNITS

2 Pages

-

Piston Filling Units

2 Pages

-

Unscrambler

1 Pages

-

Model IFC-15*

4 Pages

-

DFS Digifil? Filling Systems

2 Pages

-

Line Integration

2 Pages

-

FSV Piston Filling Unit

1 Pages

-

FUS Piston Filling Unit

1 Pages

-

KYU Piston Filling Unit

1 Pages

-

Cubitainer

5 Pages

-

CE-MNB-2000

4 Pages

-

Belt Wheel Capper

2 Pages

-

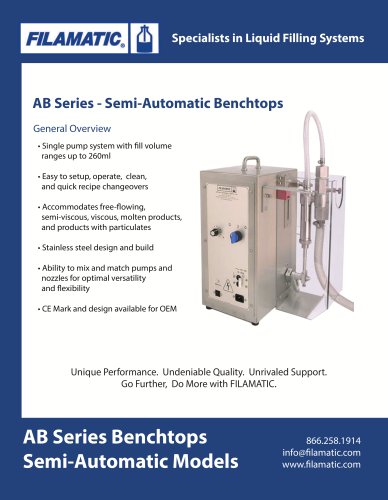

AB Series

2 Pages

-

Monobloc Family Brochure

2 Pages

-

Service Agreement

1 Pages

-

Servo Chuck Capper

2 Pages

-

Accumulators

1 Pages

-

DFS Flow Meter Filler

2 Pages

-

H-CE Molten Filler

2 Pages

-

DFS Lobe Pump Filler

2 Pages

-

DFS Piston Pump Filler

2 Pages

-

Filamatic Synchromat

2 Pages

-

Monobloc Fill/Finish System

2 Pages

Archived catalogs

-

Nozzles

2 Pages

-

In Line Family Brochure

2 Pages

-

Benchtop Family Brochure

2 Pages

-

Automatic Level Filler

2 Pages