Catalog excerpts

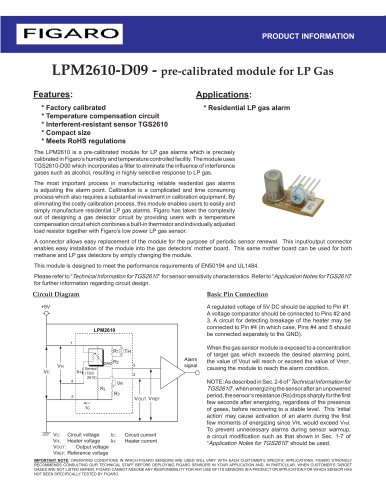

PRODUCT INFORMATION LPM2610-D09 - pre-calibrated module for LP Gas Features: * Factory calibrated * Temperature compensation circuit * Interferent-resistant sensor TGS2610 * Compact size * Meets RoHS regulations The LPM2610 is a pre-calibrated module for LP gas alarms which is precisely calibrated in Figaro’s humidity and temperature controlled facility. The module uses TGS2610-D00 which incorporates a filter to eliminate the influence of interference gases such as alcohol, resulting in highly selective response to LP gas. The most important process in manufacturing reliable resdential gas alarms is adjusting the alarm point. Calibration is a complicated and time consuming process which also requires a substantial investment in calibration equipment. By eliminating the costly calibration process, this module enables users to easily and simply manufacture residential LP gas alarms. Figaro has taken the complexity out of designing a gas detector circuit by providing users with a temperature compensation circuit which combines a built-in thermistor and individually adjusted load resistor together with Figaro’s low power LP gas sensor. A connector allows easy replacement of the module for the purpose of periodic sensor renewal. This input/output connector enables easy installation of the module into the gas detectors’ mother board. This same mother board can be used for both methane and LP gas detectors by simply changing the module. This module is designed to meet the performance requirements of EN50194 and UL1484. Please refer to “Technical Information for TGS2610” for sensor sensitivity characteristics. Refer to “Application Notes for TGS2610” for further information regarding circuit design. Circuit Diagram Basic Pin Connection A regulated voltage of 5V DC should be applied to Pin #1. A voltage comparator should be connected to Pins #2 and 3. A circuit for detecting breakage of the heater may be connected to Pin #4 (in which case, Pins #4 and 5 should be connected separately to the GND). Alarm signal When the gas sensor module is exposed to a concentration of target gas which exceeds the desired alarming point, the value of Vout will reach or exceed the value of VREF, causing the module to reach the alarm condition. VC: Circuit voltage IC: VH: Heater voltage IH: VOUT: Output voltage VREF: Reference voltage Circuit current Heater current NOTE: As described in Sec. 2-6 of “Technical Information for TGS2610”, when energizing the sensor after an unpowered period, the sensor’s resistance (Rs) drops sharply for the first few seconds after energizing, regardless of the presence of gases, before recovering to a stable level. This ‘initial action’ may cause activation of an alarm during the first few moments of energizing since VRL would exceed Vref. To prevent unnecessary alarms during sensor warmup, a circuit modification such as that shown in Sec. 1-7 of “Application Notes for TGS2610” should be used. IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED WILL VARY WITH EACH CUSTOMER’S SPECIFIC APPLICATIONS. FIGARO STRONGLY RECOMMENDS CONSULTING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO SENSORS IN YOUR APPLICATION AND, IN PARTICULAR, WHEN CUSTOMER’S TARGET GASES ARE NOT LISTED HEREIN. FIGARO CANNOT ASSUME ANY RESPONSIBILITY FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR WHICH SENSOR HAS NOT BEEN S

Open the catalog to page 1

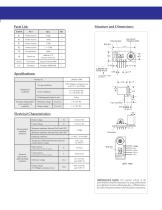

Parts List: Structure and Dimensions: Symbol Electrical Characteristics: Recommended operating conditions IMPORTANT NOTE: The original setting of the potentiometer should be checked prior to usage of the module to verify that it is in the calibrated position. LPM2610 has a blue line on the potentiometer which should be in alignment.

Open the catalog to page 2

Expected performance: under operating conditions at recommended circuit condition under std test conditions Alarming point (%LEL) Expected performance of LP gas detectors using LPM2610 and 9% LEL alarming point NOTE: When using LPM2610, typical alarm tolerances for 9%LEL of methane gas such as those shown in the figure above can be expected. However, in actual usage, alarm thresholds may vary since the threshold is also affected by such factors as the tolerances of test conditions and heat generation inside the gas detection enclosure. As a result, Figaro neither expressly nor impliedly...

Open the catalog to page 3All Figaro Engineering Inc. catalogs and technical brochures

-

TGS2600

2 Pages

-

TGS2603

2 Pages

-

TGS2602

2 Pages

-

TGS 2630

2 Pages

-

TGS2620

2 Pages

-

TGS2611-E00

2 Pages

-

TGS2611-C00

2 Pages

-

TGS2610-C00

2 Pages

-

TGS2610-D00

2 Pages

-

TGS2612

2 Pages

-

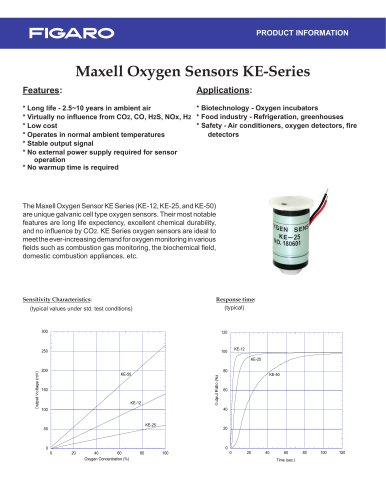

KE-12

2 Pages

-

KE-25

2 Pages

-

KE-25F3

2 Pages

-

KE-50

2 Pages

-

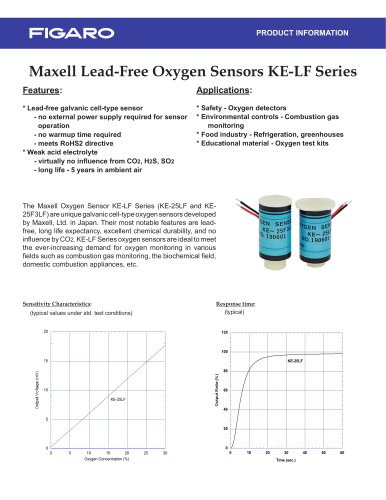

KE-25LF

2 Pages

-

KE-25F3LF

2 Pages

-

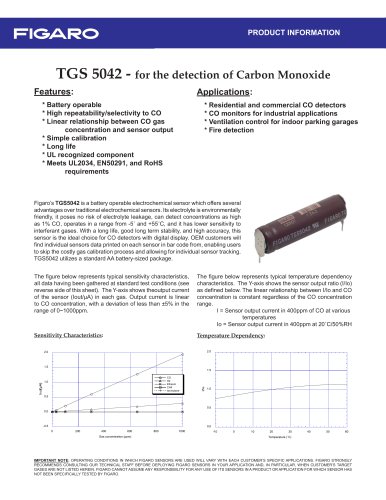

TGS5042

2 Pages

-

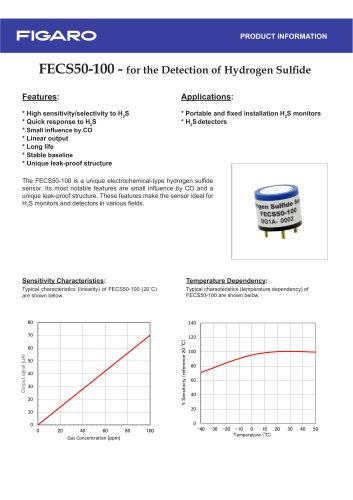

FECS50-100

2 Pages

-

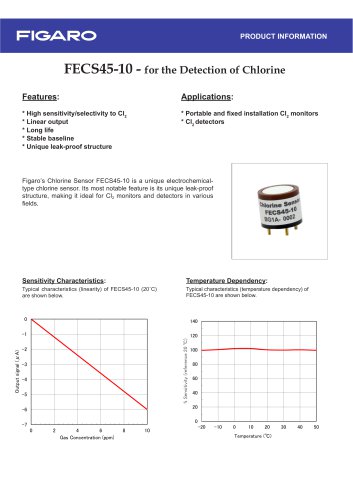

FECS45-10

2 Pages

-

FECS44-5000

2 Pages

-

FECS44-1000

2 Pages

-

FECS44-200

2 Pages

-

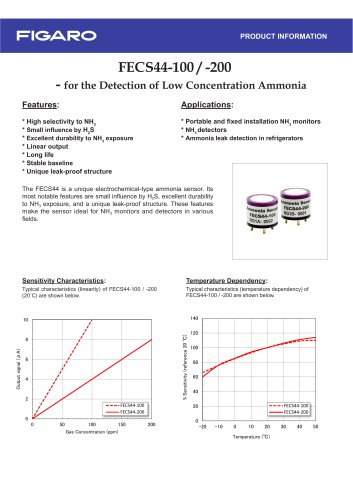

FECS44-100

2 Pages

-

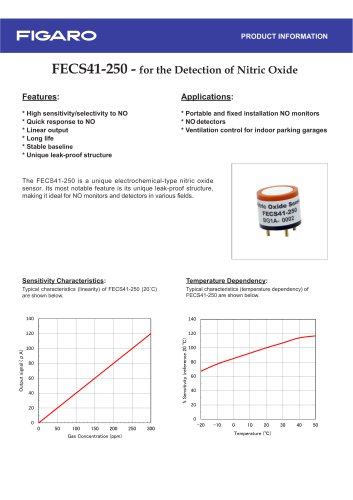

FECS41-250

2 Pages

-

FECS40-1000

2 Pages

-

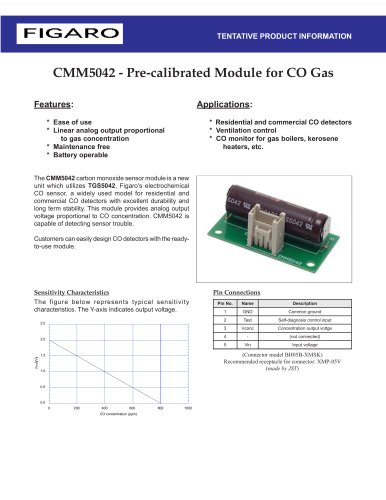

CMM5042

2 Pages

-

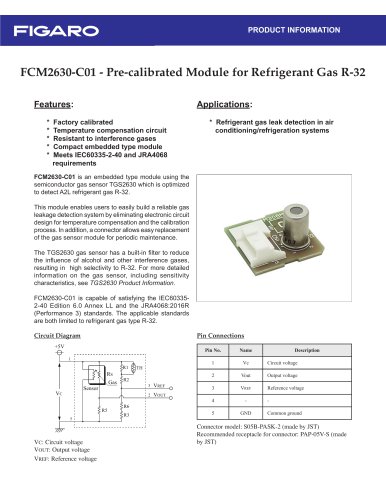

FCM2630-C01

2 Pages

-

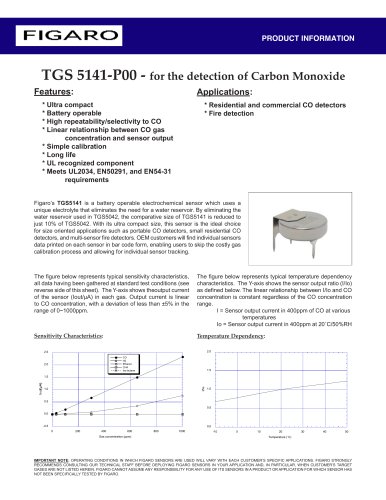

TGS5141-P00

2 Pages

-

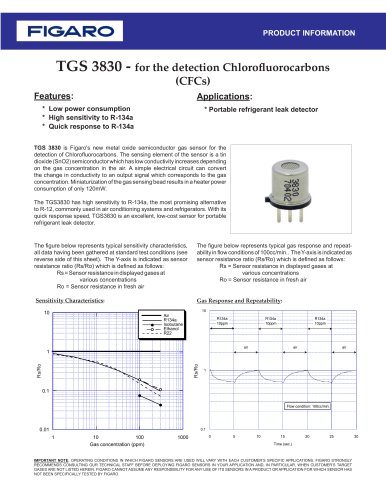

TGS3830

2 Pages

-

TGS8100

2 Pages

-

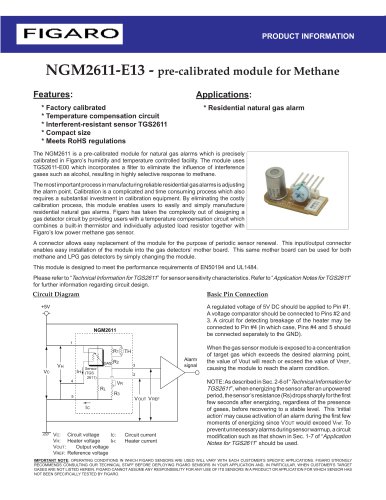

NGM2611-E13

3 Pages

-

FECS42-20

2 Pages

-

FECS43-20

2 Pages

-

CGM6812-B00

2 Pages

-

TGS6810-D00

2 Pages

-

FCM2630-E00

2 Pages

-

TGS6812-D00

2 Pages

-

TGS3870

2 Pages

-

SK-25F

2 Pages