Catalog excerpts

COMPOSITE PLATE SYSTEM FIBRO GMBH Geschäftsbereich Normalien LÄPPLE AUTOMOTIVE FIBRO LÄPPLE TECHNOLOGY

Open the catalog to page 1

COMPOSITE PLATE SYSTEM GENERAL The connection of gas compression springs in one or more systems offers the user the option to monitor the gas pressure of the gas compression springs outside the tool, adjusting them as required, filling them and discharging them. The advantages of the composite system lie in the ease of maintenance, safety and quality improvement of the gas pressure spring application in the tool. Composite plate system Composite plate systems are advantageously used where, due to minimal space conditions, there is no option to connect the gas compression springs via tubing...

Open the catalog to page 3

COMPOSITE PLATE SYSTEM DESIGN INSTRUCTIONS The following figures show the most important general design instructions and minimum dimensions to be observed. Your FIBRO specialist staff will provide you with further information. correct Blind bore holes are to be avoided as otherwise impurities can settle or chip-free cleaning after plate production is made more difficult. The minimum distance to the deep-hole bore must not be less than 5 mm. General design instructions During manufacturing, attention must be paid to the parallelism of the plate. It is therefore machine-ground to achieve the...

Open the catalog to page 4

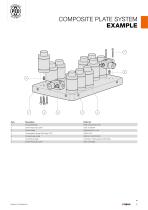

COMPOSITE PLATE SYSTEM EXAMPLE Composite plate Socket head cap screw Control fitting Compression Spring Set Screw G1/8 Connecting nipple mounted in spring base/control fitting Socket head cap screw

Open the catalog to page 5

COMPOSITE PLATE SYSTEM 2480.93.1□. – GAS SPRING, STANDARD, FOR COMPOSITE PANEL, FLAT SEAL Connection geometry Gas springs Order No. for composite plate connection Sealing surface * Number of gas spring mounting holes

Open the catalog to page 6

COMPOSITE PLATE SYSTEM 2480.93.1□. – GAS SPRING, STANDARD, FOR COMPOSITE PANEL, FLAT SEAL m (n*) Flex Guide View/Design gas spring with flat seal Technical information Pressure medium: Nitrogen Working temperature: Max. recommended extensions per minute: Ordering Code (example): Temperature related force increase: Spring force in daN at 150 bar/+20°C Order No. Initial spring force at full stroke (s) / * Number of gas spring mounting holes

Open the catalog to page 7

COMPOSITE PLATE SYSTEM 2480.94.1□. – GAS SPRING, STANDARD, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE Connection geometry Sealing surface Gas springs Order No. for composite plate connection * Number of gas spring mounting holes

Open the catalog to page 8

COMPOSITE PLATE SYSTEM 2480.94.1□. – GAS SPRING, STANDARD, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE V>max Flex Guide View/Design X - gas spring Technical information Working temperature: Temperature related force increase: Max. recommended extensions per minute: Pressure medium: Nitrogen e øb X Ordering Code (example): Spring force in daN at 150 bar/+20°C Order No. Initial spring force full stroke (s) / * Number of gas spring mounting holes

Open the catalog to page 9

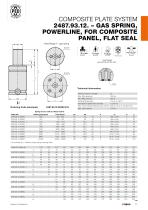

COMPOSITE PLATE SYSTEM 2487.93.12. – GAS SPRING, POWERLINE, FOR COMPOSITE PANEL, FLAT SEAL Connection geometry Gas springs Order No. for composite plate connection Sealing surface * Number of gas spring mounting holes

Open the catalog to page 10

COMPOSITE PLATE SYSTEM 2487.93.12. – GAS SPRING, POWERLINE, FOR COMPOSITE PANEL, FLAT SEAL View/Design X - gas spring Flex Guide View/Design gas spring with flat seal Technical information Pressure medium: Nitrogen Max. filling pressure: Min. filling pressure: Working temperature: Temperature related force increase: Max. recommended extensions per minute: Max. piston speed: X Ordering Code (example): m M6 x 6 tief M6 x 8 tief M8 x 6 tief M8 x 6 tief M8 x 6 tief M8 x 6 tief M8 x 12 tief M10 x 12 tief M10 x 13 tief M12 x 16 tief full stroke (s) / * Number of gas spring mounting holes s l...

Open the catalog to page 11

COMPOSITE PLATE SYSTEM 2487.94.12. – GAS SPRING, POWERLINE, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE Connection geometry * Number of gas spring mounting holes Sealing surface Gas springs Order No. for composite plate connection

Open the catalog to page 12

COMPOSITE PLATE SYSTEM 2487.94.12. – GAS SPRING, POWERLINE, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE V>max Flex Guide Technical information Pressure medium: Nitrogen Max. filling pressure: Min. filling pressure: Working temperature: Temperature related force increase: Max. recommended extensions per minute: Max. piston speed: e øb X Ordering Code (example): Spring force in daN at 150 bar/+20°C Order No. 2487.94.12.04200. 2487.94.12.06600. 2487.94.12.09500. 2487.94.12.20000. 1) at m M8 x 12 tief M10 x 12 tief M10 x 13 tief M12 x 16 tief full stroke (s) / * Number of gas spring mounting...

Open the catalog to page 13

COMPOSITE PLATE SYSTEM 2488.93.13. – GAS SPRING, HEAVY DUTY, FOR COMPOSITE PANEL, FLAT SEAL Connection geometry 0 d 1 -0,2 Gas springs Order No. for composite plate connection Sealing surface * Number of gas spring mounting holes

Open the catalog to page 14

COMPOSITE PLATE SYSTEM 2488.93.13. – GAS SPRING, HEAVY DUTY, FOR COMPOSITE PANEL, FLAT SEAL A Flex Guide View/Design gas spring with flat seal Technical information Pressure medium: Nitrogen Working temperature: Temperature related force increase: Max. recommended extensions per minute: ca. 15 up to 100 (at 20°C) Ordering Code (example): Spring force in daN bei 150 bar/+20°C Order No. Initial spring force full stroke (s) / * Number of gas spring mounting holes

Open the catalog to page 15

COMPOSITE PLATE SYSTEM 2488.94.13. – GAS SPRING, HEAVY DUTY, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE Connection geometry Gas springs Order No. for composite plate connection 2488.94.13.02400. * Number of gas spring mounting holes Sealing surface

Open the catalog to page 16

COMPOSITE PLATE SYSTEM 2488.94.13. – GAS SPRING, HEAVY DUTY, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE A Flex Guide Working temperature: Temperature related force increase: Max. recommended extensions per minute: Pressure medium: Nitrogen Ordering Code (example): Spring force in daN at 150 bar/+20°C Order No. Initial spring force full stroke (s) / * Number of gas spring mounting holes

Open the catalog to page 17

COMPOSITE PLATE SYSTEM 2490.94.14. – GAS SPRING, COMPACT, FOR COMPOSITE PANEL, WITH CONNECTING NIPPLE Connection geometry Gas springs Order No. for composite plate connection * Number of gas spring mounting holes Sealing surface Sealing surface Gas springs Order No. for composite plate connection * Number of gas spring mounting holes

Open the catalog to page 18All FIBRO GmbH catalogs and technical brochures

-

Flex Cam Unit

88 Pages

-

RECIRCULATING BALL BUSHES

12 Pages

-

THE CLEVER OPTION PILLAR CAM

2 Pages

-

AERIAL CAM UNIT 2016.27.

38 Pages

-

Standard parts

1355 Pages

-

Guide Elements

330 Pages

-

GROUND PRECISION COMPONENTS

247 Pages

-

NUOVI PRODOTTI NELL´AREA CURSORI

197 Pages

-

Composite Plate System

32 Pages

-

Catalog PDF (Peripherie)

63 Pages

-

Catalog PDF (Elastomer)

33 Pages

-

Catalog PDF (Fibrochemie)

21 Pages

-

Standard Parts SYNOPSIS

32 Pages

Archived catalogs

-

Electro-mechanical transporters

12 Pages

-

Pneumatic transporters

4 Pages

-

BOLT LOCK SYSTEM

16 Pages

-

Spacer for die release

4 Pages

-

Projection Planning Manual

64 Pages

-

Standard Parts SYNOPSIS

16 Pages

-

ROTARY TABLES

7 Pages

-

Spring Plungers

4 Pages

-

2490.14. Compact gas springs

6 Pages

-

In-Die Tapping Units (FTU)

12 Pages