Catalog excerpts

INTRODUCTION AND TABLE OF CONTENTS ENGINEERING DAIMLER, VOLVO, VOLKSWAGEN GROUP DAIMLER, VOLVO, VOLKSWAGEN GROUP 2016.208. AERIAL CAM ECO LINE CUSTOMER-SPECIFIC SERVICES APPENDIX EMERGENCY SITUATION / CONTACTS

Open the catalog to page 2

FIBRO – PARTNER FOR YOUR PRODUCTION FIBRO – an internationally successful company. As a market leader in Standard Parts and Rotary Indexing Tables, FIBRO provides products and solutions to ensure your production keeps moving. So what is the secret of the FIBRO success? Products developed in-house, tailor-made for the market with uncompromising quality. But good products are not enough on their own. FIBRO combines excellent products, the know-how and service competence of an internationally focused company, matched to the actual needs of customers - wherever they are. Hassmersheim plant...

Open the catalog to page 3

FIBRO is customer-focused – world-wide. A well-developed network of sales and service points and strategic partners ensure that help is always at hand. This ensures technical advance, world-wide experience in applications and rapid availability of products. Facts and figures on FIBRO: - founded 1958 - approximately 770 staff m - ore than 70 representatives and service stations world-wide b - ranches in France, USA, India, Switzerland, Singapore, Korea and China - ISO 9001:2000 Quality Assurance Precision parts manufacturing Rotary tables FIBRO - The worldwide pioneer in the field of rotary...

Open the catalog to page 4

IREPRESENTACIONES ■ PRZEDSTAWICIELSTWA ■ ZASTOUPENI ■ MUMESSILLER ■

Open the catalog to page 6

Experience and expertise you can rely on FIBRO Quality Assurance

Open the catalog to page 9

Experience and expertise you can rely on FIBRO Quality Assurance FIBRO is renowned for its quality world-wide. This high quality is achieved through our dedication and commitment to Quality Assurance. FIBRO testing starts on the raw material and continues right through production to the completed product. The test facilities themselves are also subject to stringent continuous testing. Only by setting itself such stringent standards can a company support its customers long term in safety, cost-effectiveness and quality. Tests during production Precision shape and contour testing equipment is...

Open the catalog to page 10

FIBRO offers a comprehensive cam unit portfolio for various requirements. The FIBRO - Cam unit configurator on our Internet site will assist you with the selection of the matching cam unit for your application. The configuration of your cam unit is done in four steps: 2. Cam unit type 3. Width of working surface (min.) 4. Height of working surface (min.) After this, an initial hitlist with max. 10 matches will be displayed. Further restrictions can be used to narrow down the selection list: 5. Cam unit working stroke (min.) 6. Cam unit working force (min.) Link to the cam unit...

Open the catalog to page 11

Order number Subject to alterations FIBRO 11

Open the catalog to page 12

OEM Order number Width [mm] Aerial/ Page Volkswagen Group with corporate brands Processing status: 17.08.2016 Are you missing an OEM in this listing? Ask us for the latest release list or check our website http://www.fibro.de/de/normalien/produktgruppen/k-schieber.html. 12 ! FIBRO Subject to alterations

Open the catalog to page 13

Order number Aerial cam unit 2016.207.

Open the catalog to page 14

14 ! FIBRO Subject to alterations

Open the catalog to page 15

INTRODUCTION AND TABLE OF CONTENTS DAIMLER, VOLVO, VOLKSWAGEN GROUP DAIMLER, VOLVO, VOLKSWAGEN GROUP CUSTOMER-SPECIFIC SERVICES EMERGENCY SITUATION / CONTACTS

Open the catalog to page 18

DESIGN, CONSTRUCTION

Open the catalog to page 19

ENGINEERING The FIBRO cam unit program offers matching system solutions for the widest range of applications. From the use in progressive punching tools with the smallest dimensions up to the demanding use in large tools. From the use in tools with small piece numbers up to premium applications in the manufacture of bodywork parts with the highest requirements in terms of precision, lifetime and process force transmission, our cam unit program offers the matching solution to your application. The fault-free operation is guaranteed by FIBRO over the guaranteed, nominal lifetime. The design...

Open the catalog to page 20

ENGINEERING DEFINITION OF TERMS Cam unit mounted in the upper die: Lifts with upper die during the course of the press cycle. Cam unit mounted in the lower die: Remains seating on the lower die during the course of the press cycle. Installed state, Depicted 100 mm in front of bottom dead center

Open the catalog to page 21

Cutting work Width Centre of the force of the stripper Centre of working force Centre of force Centre of mass n Diagonal dimension Force Stripper force Operating force Horizontal force n Force for punching Return force Retraction force Spring force Cutting force Vertical force n Working force Installation height Distance reference point / support top Height shoulder n Height of the working surface Cutting contour Cutting length Length contour element n Length Distance reference point / stop top Clamping surface top Distance reference point / stop bottom Clamping surface bottom Distance...

Open the catalog to page 23

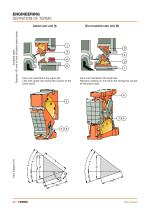

ENGINEERING DESIGN TOOL CONNECTION The size of the maximum force transferable by the cam unit is significantly influenced by the type of installation chosen. A technically correct selection of the installation type must be considered analogue to the cam unit design. The working force can be transmitted via the shoulder of the cam base on FIBRO cam units, alternatively via concealed fitting wedges on the cam base support. The shouldered installation allows maximum load values to be transferred, while a compact mounting space can be realized by installing via the concealed seating wedges. The...

Open the catalog to page 24

ENGINEERING DESIGN TOOL CONNECTION 2. Shouldering via cast shoulder in the upper area of the cam base, lower area exposed Figure 2: Cam base shouldered at top 3. Shouldering via inserted feather key between cam base and die casting in the upper area of the cam base, lower area exposed Figure 3: Cam base shouldered at top with key

Open the catalog to page 25

ENGINEERING DESIGN TOOL CONNECTION Force transmission via feather key In the case of lower requirements on the transmission of force, the cam unit can be installed in the tool by means of bracing via the key so that it is optimised to the installation space. For the mechanical machining of the feather key groove, in this case a distance from the groove geometry to the possible interference geometries in the die cast of at least 140 mm must be observed in order to avoid a collision of the milling spindle. Figure 4: Milling spindle clearance FIBRO cam units must be fitted with head cap screws...

Open the catalog to page 26All FIBRO GmbH catalogs and technical brochures

-

Flex Cam Unit

88 Pages

-

RECIRCULATING BALL BUSHES

12 Pages

-

THE CLEVER OPTION PILLAR CAM

2 Pages

-

AERIAL CAM UNIT 2016.27.

38 Pages

-

Standard parts

1355 Pages

-

Guide Elements

330 Pages

-

GROUND PRECISION COMPONENTS

247 Pages

-

NUOVI PRODOTTI NELL´AREA CURSORI

197 Pages

-

COMPOSITE PLATE SYSTEM

32 Pages

-

Composite Plate System

32 Pages

-

Catalog PDF (Peripherie)

63 Pages

-

Catalog PDF (Elastomer)

33 Pages

-

Catalog PDF (Fibrochemie)

21 Pages

-

Standard Parts SYNOPSIS

32 Pages

Archived catalogs

-

Electro-mechanical transporters

12 Pages

-

Pneumatic transporters

4 Pages

-

BOLT LOCK SYSTEM

16 Pages

-

Spacer for die release

4 Pages

-

Projection Planning Manual

64 Pages

-

Standard Parts SYNOPSIS

16 Pages

-

ROTARY TABLES

7 Pages

-

Spring Plungers

4 Pages

-

2490.14. Compact gas springs

6 Pages

-

In-Die Tapping Units (FTU)

12 Pages