Website:

FIAM

Website:

FIAM

Group: Fiamgroup

Catalog excerpts

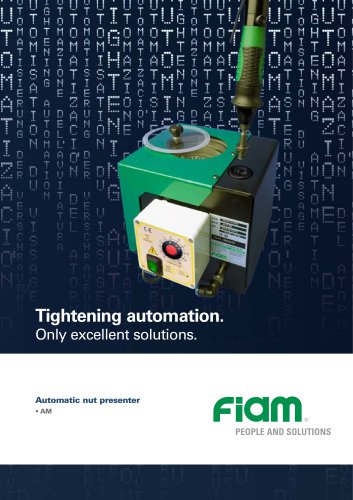

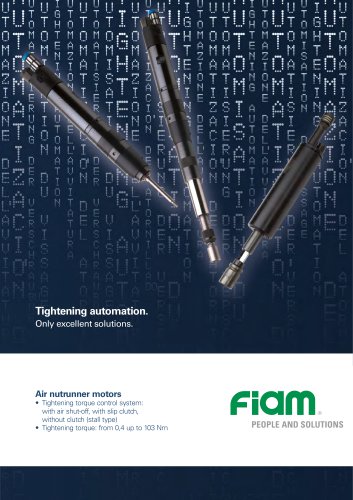

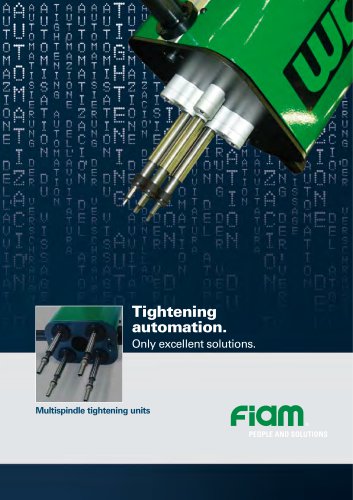

Tightening automation. Only excellent solutions. High-tech automatic tightening solutions

Open the catalog to page 1

Automatic tightening solutions. The best of Fiam for your production. They allow to control, monitor, analyze, diagnose and programme in real-time. They can be integrated perfectly with the network control systems of the production site. They guarantee a very high control of the productive process and consequently of the quality of the assembled products. These are the new Fiam solutions for industrial tightening: a concentrate of innovation and reliability.

Open the catalog to page 2

For any threaded element Semi-automatic solutions: a valuable help for operators Multi-spindle tightening units: they assemble several fasteners simultaneously Brushless DC driven nutrunner motor (with Off Set device) installed on fastening slide and anthropomorphic arm Anthropomorphic robot, versatile and always convertible Electronic axis to ease assembly on different surface Manual use on cartesian arm Pallets automatic line to fasten the screws on thermo-hydraulic collectors

Open the catalog to page 3

Configurations High technology DC driven nutrunner motors with feed and control unit: perfect synergy for high quality assemblies • This wide range of high-tech DC electronic nutrunner motors along with the controller guarantees extreme precision and accuracy of every industrial assembly • Several configurations with different modes of torque control and monitoring to solve any tightening need, even most difficult ones • Suitable for all industrial fields from motor vehicle to aerospace, from electric household appliances to electro-mechanical field. These solutions guarantee allover: high...

Open the catalog to page 4

CP-MAX CP nominal CP-MIN CP-Threshold Different control modalities available: torque control with angle monitoring, angle control with torque monitoring, only torque control. Rotation angle • Feed and control unit

Open the catalog to page 5

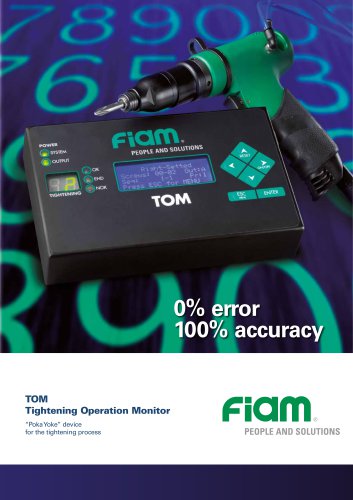

Feed and control unit TCS-B E: the intelligent simplicity TCS-B E (Tightening Control System - Basic - Evolution) are innovative and compact units that include electronic feeding to the motors, programming and control of each stage of tightening cycle. They control both current control and torque/angle nutrunner motors. 5 strategies: it is possible to choose between screw drive-engagement, torque, torque/angle, angle/torque, loosening. 5 programmable modalities, to guarantee reliability and working speed Optical outcomes visualization for an immediate understanding through OK, NOK, RUN leds...

Open the catalog to page 6

TCS-B Programmer TCS-B Programmer is the software supplied with the unit and allows a lot of advantages: Simple, intuitive connections and programming • Simple, intuitive installation on a PC with the standard equipment supplied (RS232 cable) • System configuration through the quick guide, document “step by step” to immediately start the system • System calibration: the motors connected to this unit are on display; it is sufficient to select the motor connected and all parameters are automatically set • OFF LINE programming: it is possible to create, modify and save the tightening programs...

Open the catalog to page 7

Layout TOUCH PANEL PROFIBUS/ PROFINET/ MODBUS TCP-IP LIGHT COLUMN WITH ALARM PC ETHERNET SOCKET PROGRAM SELECTOR TCS-B E FEED AND CONTROL UNIT

Open the catalog to page 8

Accessories upon request INTERFACE UNIT TCA The Interface unit (Tightening Control Adapter) is available in 2 versions: • TCA-PN Interface Unit for Profinet e Modbus TCP-IP TCA-PB Interface Unit for Profibus. Both units work with the TCS-B E, are entirely designed and manufactured by Fiam and allow to interface and to control digital I/Os and export all output data directly through the PROFINET / MODBUS TCP-IP and PROFIBUS comunication protocol. The TCA-PB model has an additional gateway for Profibus protocol. From the PLC Master, through communication protocols TCA is able: • To export...

Open the catalog to page 9

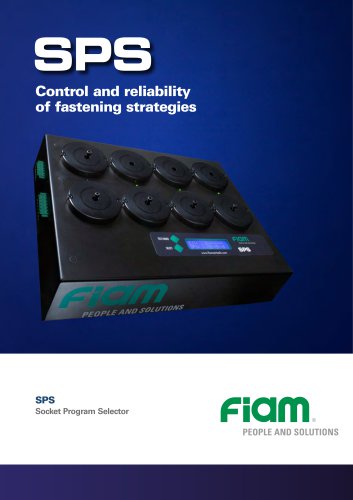

PROGRAM EXPANSION TCS-B E units can be activated to further 4 tightening programs (for a max of 8 programs). It is sufficient to buy the activation code that will be supplied separately. Cod. 686200904 Program Expansion Tightening programs

Open the catalog to page 10

Technical features Feed and control unit TCS-B E 9,5÷10,6 Results to be stored OK /NOT OK cycles Torque/angle/time values General statistics Weight (Kg) Dimensions (mm) Output tension driver motor (dc link) Max power Display (lines/columns) Graphic display Programming keypad Display torque/time curve Italian – English French German Spanish Automatic nutrunner configuration Led (OK NOK RUN) Number of Motors to manage (channels) Feed and control unit TCS-B E BASIC FUNCTIONS Programs number Strategies number OK NOT OK results Error Tightening sequence programming Program instructions ADVANCED...

Open the catalog to page 11

High technology DC driven nutrunner Brushless solutions for every need High technology DC driven nutrunner motors (brushless) don’t need maintenance and thanks to absence of coal dust eliminate pollution in the working area Built-in resolver/encoder: they guarantee an elevated resolution in the angle measurement and therefore it assures an excellent tightening process control Motor appropriate selection and accurate programming (angle, torque, time etc...) reduce the need of post process controls with remarkable production benefits Compact design, reduced dimensions and weights: ideal with...

Open the catalog to page 12

TORQUE AND ANGLE CONTROL Equipped with an electronic transducer to read the torque applied to the screw; while the angle is read directly by appropriate sensors.

Open the catalog to page 13

Current control Legend 15 = Power of the motor/10 • MC = Nutrunner motor • B = Electronic brushless • 05 = Maximum torque in Nm • C = Current control • 1 = Output with square drive without axial compensator • 2 = Output with square drive with axial compensator Legend Reversibility: All models are suitable for tightening and untightening operation • Noise level has been measured in accordance with ISO 3744 and ISO 15744 standards (inf. to 72 dBA). • Accessory drive: male square drive in accordance with ISO 1174-1. • The code number must be used when ordering. Standard equipment (supplied...

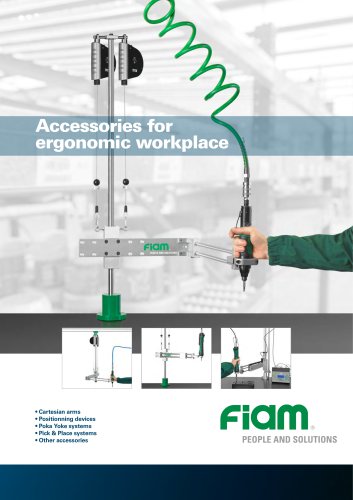

Open the catalog to page 14All FIAM catalogs and technical brochures

-

General catalog of Fiam solutions

160 Pages

-

General catalog of Fiam solutions

188 Pages

-

Automatic screw presenters

16 Pages

-

Automatic nut presenters

4 Pages

-

Air nutrunner motors

24 Pages

-

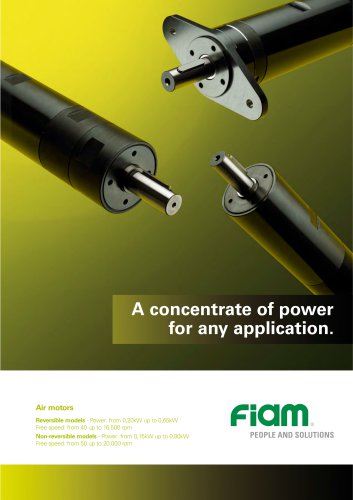

Air motors

50 Pages

-

Penna pneumatica

2 Pages

-

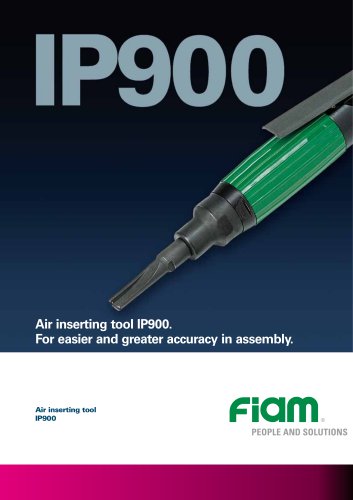

Air inserting tool IP900

4 Pages

-

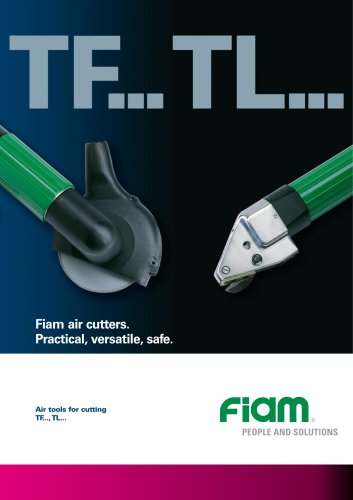

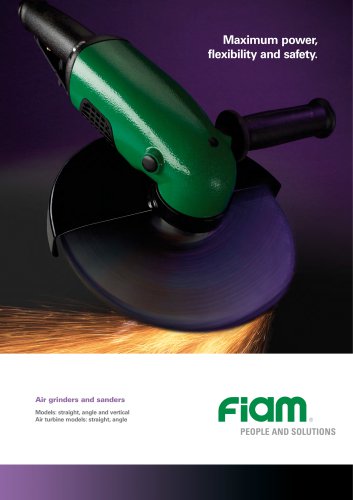

Air grinders and sanders

16 Pages

-

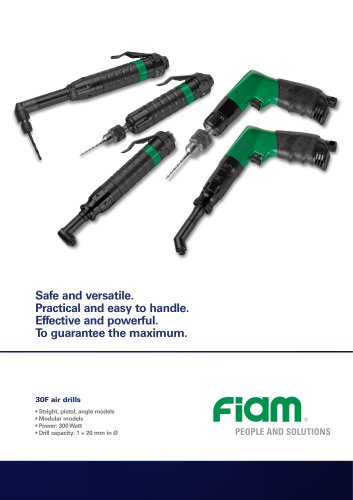

30F-Air drills

10 Pages

-

Air drills

24 Pages

-

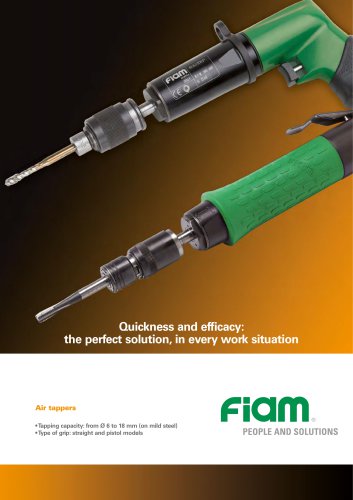

Air tappers

16 Pages

-

Aerospace Solutions

42 Pages

-

Torque readers

8 Pages

-

Cordless screwdrivers

4 Pages

-

Oil pulse wrenches IHE

4 Pages

-

Air screwdrivers CDE

4 Pages

-

Air angle nutrunners

22 Pages

-

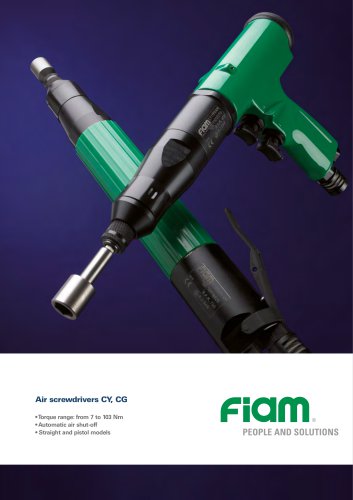

Air screwdrivers CY, CG

4 Pages

-

26C Air screwdrivers

20 Pages

-

15C Air screwdrivers

20 Pages

-

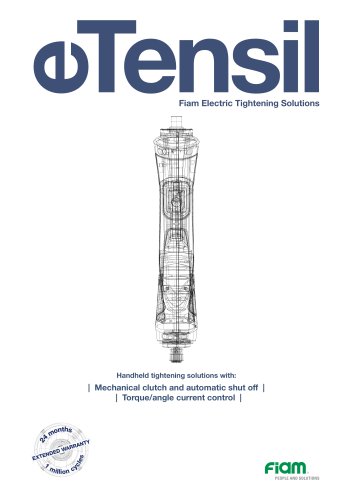

eTensil for manual use

42 Pages

-

Torque readers

8 Pages

-

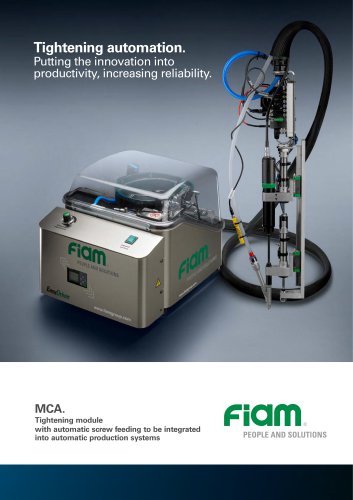

Auto feed tightening module MCA

40 Pages

-

Air motors

50 Pages

-

Tightening automation

16 Pages

-

Air angle nutrunners

22 Pages

-

Aerospace Solutions

42 Pages

-

Drills-30F

10 Pages

-

Air grinders and sanders

16 Pages

-

26C Air screwdrivers

20 Pages

-

15C Air screwdrivers

20 Pages

-

AM-Automatic nut presenter

4 Pages

-

Cordless screwdrivers

4 Pages

-

Air screwdrivers CDE

4 Pages

-

Air nutrunner motors 40 Nm

24 Pages

-

Air drills

24 Pages

-

Air tappers

16 Pages

-

Air screwdrivers 15C

16 Pages

-

Oil pulse wrenches IHE

4 Pages

-

Air marking pen

2 Pages

-

Air inserting tool IP900

4 Pages