Catalog excerpts

By Every Measure, Ferrite’s Revolutionary Polarized Feeds Change the Economic Dynamics of Industrial Microwave Processing. Microwave Energy Distribution Ferrite’s patented polarized feeds increase the quantity and uniformity of microwave fields present in the application cavity. These density and pattern improvements allow users to capitalize on the most beneficial processing aspects of microwave energy, processing speed and product penetration. Fixed in place but with variable launch angles and rotation options, polarized feeds can be finitely tailored to optimize absorption in a given application. Competing microwave feed technologies are less adaptable and have inherent limitations which lead to energy loss, non-uniform patterning and hot/cold spots. Maintenance Polarized feeds also significantly reduce maintenance costs. The technology relies on no moving parts and never needs replacement. Use of polarized feeds on a “typical” industrial microwave installation equates to a replacement part savings of between $5,000 and $15,000 per year when measured against competing technology relying on motorized components. In addition, loss of revenues caused by system down time and maintenance of the feeds is eliminated. Efficiency On average the polar feed technology has a 1% efficiency advantage over other feed technologies, due primarily to the fact it does not require a transition from waveguide to coaxial transmission carriers. This offers users a significant advantage, especially at the power levels typical of industrial applications of between 75kW to 450kW. Over the course of only a single year at these power levels, a 1% increase in efficiency represents a substantial operational savings. Applications Polar Feeds are suitable for use in all applications and can be readily incorporated into existing facilities. While offering all users the common advantage of an efficient, maintenance free and uniform application of microwave energy, customers who seek to dry their products receive perhaps the technology’s most unique characteristic. Due to the spinning nature of the voltage component of the polarized signal, Ferrite’s SPIN-WAVE TM industrial microwave dryers are capable of achieving previously unattainable dewatering efficiencies. For more on this technology please refer to our website at www.ferriteinc.com • No moving parts - Eliminates operating and maintenance costs associated with antennas, covers, and flanges. • Eliminates equipment down time and improves throughput performance. • Eliminates arcing and burning while increasing the uniformity of the microwave field. • Eliminates inventory costs associated with microwave feeds. • Increases throughput and energy efficiency while enhancing product quality. High Power Microwave Systems and Technology. Ferrite Microwave Technologies, LLC 165 Ledge Street, Nashua, NH 03060 toll free: 800-854-1466 tel: 603-881-5234 fax: 603-881-5406 www.ferriteinc.com

Open the catalog to page 1All Ferrite Company catalogs and technical brochures

-

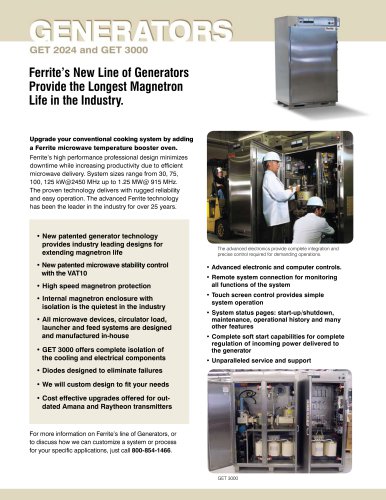

GET 2024

2 Pages

-

MIP 9 Booster oven

1 Pages

-

MIP 12 continuous tempering

2 Pages

-

MIP 10 batch tempering

2 Pages

-

MIP 6 index batch tempering

2 Pages

-

MIP 4 Mini batch tempering

2 Pages