Catalog excerpts

Versatile Mini Tempering Oven Offers Speed, Control, Convenience and Cost Savings. Tempering to Order Food service operations that need to temper moderate quantities of food in a hurry and have limited space, can rely on the Mini Batch Microwave from Ferrite for tempering on demand. The MIP 4 is ideal for batch tempering of frozen meat, fish, poultry, fruit or bakery products in a fast-moving food preparation environment, such as that aboard cruise ships. This unit can temper up to 1,500 pounds (680 kg) of raw, frozen product per hour. It automatically raises the average temperature of frozen product to between 22 and 29 degrees Fahrenheit (-2 degrees to -1 degree Celsius) at the touch of a button. A complete system, the MIP 4 consists of a compact microwave oven and a 75 kilowatt microwave transmitter. Even, Consistent Tempering The MIP 4 provides uniform heating and enables tempering from lower starting temperatures with consistent heating and Ferrite’s unique rotary table. Precise computer control of processing time provides predictable temperature rise - or tempering - and end temperature. Typically, this microwave oven can temper a 55 pound (25 kg) box of beef in 65 seconds. Advanced Technology Decades of diligent research and development, as well as real-life tempering trials for customers in widely varied areas MIP 4 Highlights • Eliminates tempering rooms or racks, saves space and multiple handling sequences and the related mess • Allows predictable ending product temperature • Adds processing flexibility with tempering on demand for better service • Improves quality and yield • Retains flavor and protein compounds for consumers • Improves sanitation and saves labor stripping cartons • Reduces disposal of waste cardboard • Simplifies compliance with government sanitation regulations and guidelines • Reduces potential for airborne contaminants to infect food through the use of shortened tempering process of the food processing industry, have driven the industryleading technology contained in the MIP 4 transmitter. A Mini System The MIP 4 has a 3-foot by 4-foot (.9 meter by 1.3 meter) tempering microwave oven and comes complete with its own 75 kilowatt microwave transmitter. Ferrite’s MIP 4 industrial microwave tempering unit operates at 915 MHz and produces approximately 260,000 BTUs per hour for superior food processing performance. Precise Computer Control The transmitter is controlled by a Programmable Logic Controller (PLC) processor. The PLC operates the control software for the transmitter. The PLC processor enables constant power operation at preset power levels. It also provides a digital display of status information including actual versus set point power, and fault diagnosis. Warranteed For Dependability The MIP 4 Tempering System is warranteed for a period of one year. Both in- and out-of-warranty service support is provided by Ferrite Certified field technicians.

Open the catalog to page 1

Specification Details Electrical Specifications (per transmitter) United States: INPUT LOAD 480 volts, 3 phase, 50 or 60 cycle, 72 amps, 60 KVA 440 volts, 3 phase, 50 or 60 cycle, 80 amps, 60 KVA 0.9 power factor Microwave Isolation The MIP 4 transmitter is electrically isolated from the process oven by an integral microwave circulator that helps provide long megatron tube life. Because of the efficiency of Ferrite’s waveguide power transmission, it is possible to install the transmitter in a remote location. Specifications: 75 kW, 915 MHz Magnetron microwave power source Transmitter...

Open the catalog to page 2All Ferrite Company catalogs and technical brochures

-

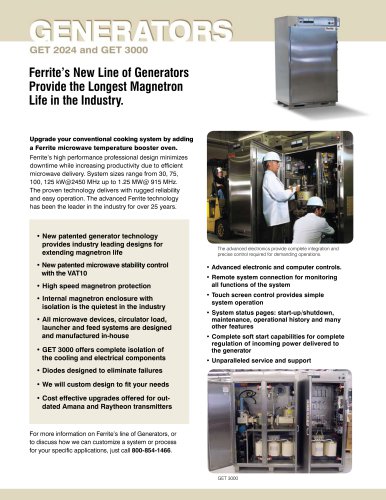

GET 2024

2 Pages

-

MIP 9 Booster oven

1 Pages

-

MIP 12 continuous tempering

2 Pages

-

MIP 10 batch tempering

2 Pages

-

MIP 6 index batch tempering

2 Pages