Catalog excerpts

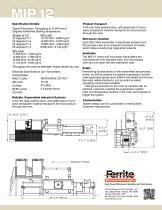

Ferrite Continuous Tempering Takes Frozen Products from Zero to 28 Degrees in Minutes, Not Days! Precision Tempering Control from Ferrite Greatly reduce tempering time for frozen meat, fish, poultry, fruit or bakery products from days to minutes with Ferrite’s MIP 12 Continuous Tempering Tunnel System. Temper up to 17,000 pounds (7,700 kg) of zero degree Fahrenheit (-18 degrees Celsius) product per hour. Continuous tempering enables precise control of product temperature for further processing, such as slicing, dicing, forming, and molding. MIP 12 Highlights • Adds flexibility to processing by allowing tempering on demand • Allows predictable product ending temperature • Eliminates the need for tempering rooms or racks, saves space and multiple handling sequences • Improves quality and yield • Allows remote system troubleshooting by Ferrite service technicians via modem access to PLC controls • Industry proven, user-friendly Ferrite system software and Allen-Bradley controls A Modular Tempering System The basic system consists of a single 4-foot by 4-foot by 8-foot long tunnel (1.2 meters by 1.2 meters by 2.5 meters with up to four dependable 75 kilowatt transmitters. Product temperature control is maintained with simple belt speed or transmitter power adjustments. Additional transmitters, up to a total of four, can be added to the unit to significantly increase production output. Simplify the Tempering Process The MIP 12 simplifies the food tempering process. It eliminates tempering rooms and racks, along with the resulting sanitation issues and brings precision to your food processing procedures. Microwave tempering gives control over the production process and helps plan both input and output on a daily, weekly or monthly basis. Product quality and yield are improved and drip loss is minimized. Flavor and protein compounds remain in the product and are passed along to the consumer. Controlled temperature rise and predictable end temperature ensures processing flexibility.

Open the catalog to page 1

Specification Details Typical Production Throughput at 75 kW from 0 Degrees Fahrenheit Starting Temperature. Throughput amounts are estimates. Actual results may vary. Electrical Specifications (per Transmitter): United States: INPUT LOAD MICROWAVE OUTPUT 50/60 cycles 0.9 power factor Reliable, Dependable Industrial Systems A 20-inch wide positive drive, articulated belt of micro- wave transparent material transports the food product Product Transport A 20-inch wide positive drive, articulated belt of micro- wave transparent material transports the food product Microwave Isolation Each GET...

Open the catalog to page 2All Ferrite Company catalogs and technical brochures

-

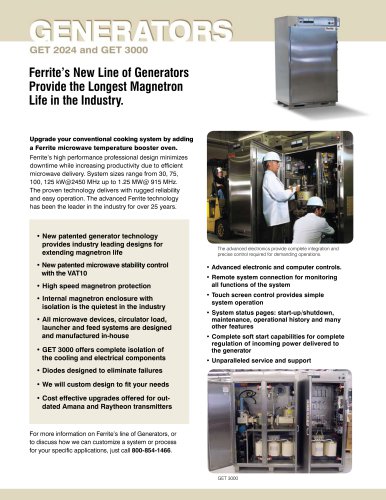

GET 2024

2 Pages

-

MIP 9 Booster oven

1 Pages

-

MIP 10 batch tempering

2 Pages

-

MIP 6 index batch tempering

2 Pages

-

MIP 4 Mini batch tempering

2 Pages