Catalog excerpts

Ferrite Batch Processor Tempers 300 Pounds of Meat, Fish, or Bakery Product in Four Minutes. Customized Batch Tempering Set up precise batch tempering of frozen meat, fish, poultry, fruit or bakery products in just minutes with Ferrite’s Batch Processor Microwave Oven MIP 10. This tempering unit is ideal for portion-control plants, ground beef and poultry operations, sausage kitchens, bakeries and frozen prepared-food manufacturing. During a single shift, it automatically and precisely raises the temperature of up to 4,000 pounds (1,816 kg) of frozen product to 28 degrees Fahrenheit (-2 degrees Celcius). Uniform Product Heating As a leader in industrial microwave oven development, Ferrite offers the widest variety of cooking and tempering microwave ovens on the market. The MIP 10 provides uniform heating resulting in consistent, efficient tempering from lower starting temperatures. Precision Control Precise computer control of processing time provides predictable temperature rise, or tempering, and product end temperature. Typically, this microwave oven tempers a load of about 300 pounds (136 kg) in four minutes (see chart on back for examples). MIP 10 Highlights • Adds processing flexibility with tempering on demand • Allows predictable ending product temperature rise for consistent, quality production • Eliminates tempering rooms or racks, saves space and multiple handling sequences • Improves quality and yield • Improves sanitation and saves labor stripping cartons • Retains flavor and protein compounds for consumers • Simplifies compliance with government sanitation temperature control regulations and guidelines A Complete System The basic system consists of a 50-inch by 42-inch (1.3 meter by 1.1 meter) microwave oven, one Ferrite GET 2024 75 kilowatt microwave transmitter and a loading table on convenient rollers. The oven size permits a uniform loading procedure for the simultaneous processing of one 10-inch high (254 millimeter) tier of containers from a 40-inch by 48-inch (1.02 meter by 1.22 meter) pallet. Ferrite Keeps Your Facility Clean Tempering food with the Ferrite microwave oven retains protein and flavor compounds for tastier, fresher products. With the MIP 10 installed, tempering rooms and the resulting drip or liquid runs that are common in the food processing industry are eliminated. Warranteed For Dependability The MIP 10 is covered by a full one-year warranty. Both in- and out-of-warranty service support is provided by Ferrite Certified field technicians.

Open the catalog to page 1

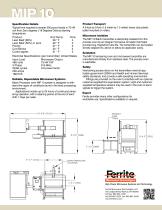

Specification Details Typical time required to temper 300 pound loads in 75 kW unit from Zero degrees (-18 Degrees Celcius) starting temperature. Product: End Temp: Time: Lean Beef (85%) 26 ° F 4 Lean Beef (50%) or pork 22 ° F 2 Poultry 27 ° F 5 Cod Blocks 22 ° F 3 Cored apples 21 ° F 3 Electrical Specifications (per transmitter) United States: Input Load Microwave Output 480 volts 75 kW CW 3 Phase 915 MHz 50/60 cycles 0.9 power factor 200 amps 166 KVA Reliable, Dependable Microwave Systems Batch Processor oven MIP 10 system is designed to withstand the rigors of conditions found in the...

Open the catalog to page 2All Ferrite Company catalogs and technical brochures

-

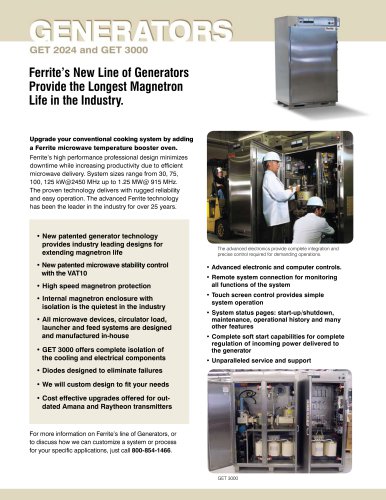

GET 2024

2 Pages

-

MIP 9 Booster oven

1 Pages

-

MIP 12 continuous tempering

2 Pages

-

MIP 6 index batch tempering

2 Pages

-

MIP 4 Mini batch tempering

2 Pages