Website:

Feintool Technologie AG

Website:

Feintool Technologie AG

Group: Feintool

Catalog excerpts

deciding difference

Open the catalog to page 1

Precision components ... ... for compact clutches and transmissions ... ... for dynamic and economical vehicles

Open the catalog to page 2

future Feintool is a technology company specializing in the development of f ineblanking systems and the high volume production of sophisticated fineblanked and formed components. The group attributes its leading p osition to its globally unique expertise and to the close partnerships it maintains with its customers. Feintool has focused its innovation efforts on customer needs for over 50 years. Some 2,000 dedicated employees are committed to this principle, consistently developing products that break new ground and push the technology envelope.

Open the catalog to page 3

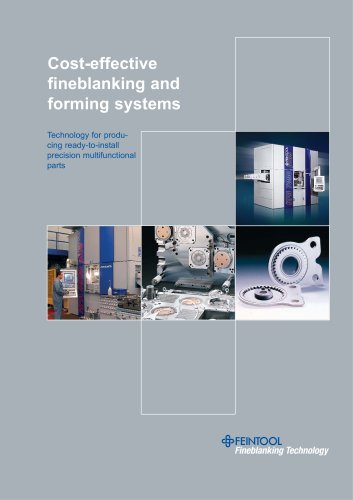

Fineblanking and cold forming are processes that are synonymous with cost-effectiveness, precision and quality. This makes them particularly suitable for demanding automotive engineering applications. Fineblanking: Clip for diesel engine injectors Orbital forming: Differential bevel gear Cold forming: Clutch plate carrier housing with internal spline

Open the catalog to page 4

Sophisticated component geometries are the hallmark of Feintool technology. Gener ating high-integrity, clean-sheared surfaces in a single operation is the outstanding quality characteristic that sets fineblanking apart from all other stamping and blanking processes. The benefits: component precision and flatness, making costly finishing unnecessary. All it takes to produce a precision component is a fineblanking press and a tool. Parts are ready to install: blanked, formed, deburred. For example, clips made of high-strength steel that make diesel engine injectors work. They are produced...

Open the catalog to page 5

A question of More complex, faster, more efficient – Feintool develops fineblanking presses and tools for the cost-effective manufacturing of precision c omponents. At the focal point: the servo drive. Seatbelt tongues: The tool fineblanks, bends and deburrs in a single process High uptimes: Feintool systems produce at competitive unit costs Integrated removal system: Components exit the tool undamaged

Open the catalog to page 6

f technology Increased output, process stability. The bottom line: enhanced system uptimes producing cost-effective, high-quality components. Zerodefect parts ejected from the tool by the removal system is the benchmark to which both the press operators and the press design engineers aspire. Feintool is consistently developing advanced technologies for its fineblanking and forming systems. A typical example is the servo drive for our mechanical and hydraulic fineblanking presses. Tool life is extended as the servo drive allows the technology cycle to be precisely regulated down to split...

Open the catalog to page 7

Components produced by Feintool are developed jointly with the customer. Innovative components that are more complex, lighter but at the same time more economical. Components that allow customers to successfully implement their own innovations. Comfort: Gear component for seat adjuster Drivetrain: Disc carrier for clutches and transmissions Safety: Components for airbag systems Up to 200 parts per vehicle are manufactured with Feintool systems

Open the catalog to page 8

Feintool utilizes the fineblanking, cold forming and orbital forming processes to produce parts. Economical and efficient quality. Because the functional surfaces are smooth and free of cracks. Because tools combine multiple steps and generate complex geometries. Also because forming systems with secondary operations such as CNC machining or laser welding can constitute complete process chains. Feintool production processes are challenging. They demand the in-depth technological expertise needed to design parts and build tools in such a way that volume production of precision components at...

Open the catalog to page 9

A feeling of Feintool cultivates close partnerships with its customers. From c omponent design to spare parts management, the entire value-added chain of fineblanking and forming is covered. Service hotline: On-call round the clock Together with the customer: Developing parts and tools Quality management: Forward-looking in planning and during roduction p

Open the catalog to page 10

security Feintool takes responsibility for ensuring that customer investments pay off. Partnerships begin with the initial inquiry. It is enough to know the subsequent function of a component in order to find the appropriate solution, not just in terms of parts design but also in the resulting definition of tool, press and peripherals. Whichever configuration ultimately becomes reality depends on a single factor: customer benefit. Or in other words, process stable, highly efficient com ponent production. Quality assured. Even though all efforts invariably emphasize the technical outcome,...

Open the catalog to page 11

Questioning, researching, progressing – the response to market challenges lies in innovation. Prototyping: Early testing Engineering: Cross-team know-how Research: New protective coatings

Open the catalog to page 12

Every innovation begins with communication. With people discussing, taking what has already been achieved as a basis to ask new questions. At Feintool the results are reflected by more than a hundred tools being created each year, adding to a knowledge database in which more than 10,000 solutions are stored. Interdisciplinary engineering teamwork aims at identifying the best possible outcome for each task through the interplay of component design, material selection and tool concepts. Simulations instead of expensive trial-anderror loops and prototyping under production conditions reveal...

Open the catalog to page 13

Strong indivi Innovation requires know-how – Feintool employees develop and enhance sustainable professional and personal skills. Training: Learning at a high level Experience: Ensuring quality Exchange: Mutual cultural enrichment

Open the catalog to page 14

iduals Feintool apprentices are regularly among the best in their class. Those high standards of the dual training system, as found in S witzerland and Germany, are similarly applied by Feintool at each of its plants around the world. Feintool knows that an exceptionally well-trained young workforce can carry its highly specialized know-how into the future. Coupled with education and sound training, Feintool continues to cultivate a culture of extensive knowledge, even after the end of the qualification period, helping the next generation grow into self-confident individuals. years of...

Open the catalog to page 15All Feintool Technologie AG catalogs and technical brochures

-

System Parts Europe

16 Pages

-

System Parts Japan

16 Pages

-

System Parts China

12 Pages

-

Cold forming brochure

12 Pages

-

Fineblanking technology

20 Pages