Catalog excerpts

INTEGRA® 86 Automatic drum filler Reliable and well tested. The automatic drum filler INTEGRA® 86 is working with 6 stations, thus increasing the efficiency even more. The work processes are continuously monitored. For example, nominal torques for containers and closures are automatically checked. Also possible errors such as missing bunghole seals or wedged plugs are detected by the automatic drum filler. BENEFITS Automatic and monitored opening, closing and sealing, even with leakage test and over-pressure bunging Torque evaluation during bunging Touch panel Components in stainless steel and acid protection design available Protective cabin with lock gates available Filling of 50 l to 230 l ISO drums with optional accessories Variety of essential accessories TECHNICAL DATA Below-surface 86.1-0-P0 de-bunging/ filling de-bunging/ filling bunging Working cycle positioning/ de-bunging / filling bunging /sealing A HAVER & BOECKER Company

Open the catalog to page 1

INTEGRA® 86 Automatic drum filler 10 Configuration example Oberflächenbehandlung surface treatment Schweissnahtvorbereitung / edge preparation: ISO 9692 Allgemeintoleranz für Schweißkonstr.: General weldment tolerances: DIN EN ISO 13920-AE Schnittgüte für Brennteile / cut quality for cutting parts ISO 9013 - 1A Verantwortl. Abt. / Resp.dept. Technische Referenz / Technical reference Dokumentenart / Docum ent type Titel / Title TECHNICAL DATA ATEX design Electrical design Weighing range External control 2x dry contacts or 4-20 mA signal for controlling an on-site pump or a pilot valve for...

Open the catalog to page 2All Feige Filling catalogs and technical brochures

-

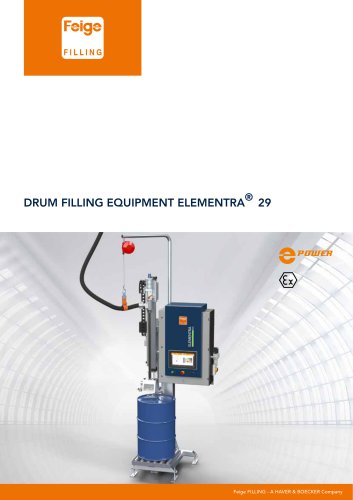

ELEMENTRA® 29

3 Pages

-

INTEGRA® 84

2 Pages

-

Imagebroschuere

24 Pages

-

Our Product range

2 Pages

-

Time to chain

3 Pages

-

CAN FILLING

20 Pages

-

PAIL FILLING

20 Pages

-

PALLET FILLING

20 Pages

-

DRUM FILLING

20 Pages

Archived catalogs

-

Sommer-Feige Brsochüre

4 Pages