Catalog excerpts

COMPETENCE IN DRUM FILLING FEIGE FILLING – A MEMBER OF THE HAVER® GROUP

Open the catalog to page 1

HIGHEST EFFICIENCY IN DRUM FILLING Feige Filling GmbH is a traditional German medium-sized company in Bad Oldesloe. Founded in Hamburg in 1972, the company has developed into the market as technology leader in the eld of lling technology by its innovative strength and open-mindedness. Feige Filling stands for gravimetric lling equipment for lling of liquid and pasty products with calibrated accuracy. We have the suitable lling technology to meet your challenge Let us help you ll your drums Whenever drums need to be lled, the use of lling equipment is ine- The modular assembly system of the...

Open the catalog to page 2

FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 3

SAFETY - ACCURACY - FLEXIBILITY Repeatable accuracy as well as the highest degree of safety during product lling are fundamental requirements which have to be met by lling equipment meeting the highest quality standards Filling - safely Measuring with calibrated accuracy With the Feige lling valve, you ll your liquid and viscous products with The FEIGE weigh scale terminal is the a proportional or multi-stage dosing heart of the equipment. Measuring system. The lling valve is dimensi- the dosed lling volumes with calibra- oned in accordance with your requi- ted accuracy is carried out with...

Open the catalog to page 4

Safety Functions The filling valves are equipped with important safety functions such as: Closing / opening with compressed air Closing with spring force Relieved of product pressure Leakage monitoring of the sealing space Fill level check Minimum dead space 255 Product files, expandable Protocol of weighing results and statistics Alphanumeric entry through prompting Storage of operation data Label printer protocol printer Measuring device Load cell Mass flow meter FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 5

CONCENTRATED KNOW-HOW IN INTRALOGISTICS If you are planning a seamless overall concept of lling equipment with end packaging, palletising, conveying and marking technology, talking with the specialists of FEIGE FILLING will certainly be of assistance Turnkey complete solutions In the eld of lling, FEIGE FILLING Innovative factory and system design (FEIGE FACTORY DESIGN) will project your complete turnkey equipment for the solution of com- You would like to look at your new plex logistic tasks. The equipment re- equipment long before it is imple- quired by the most different industrial...

Open the catalog to page 6

FROM FIRST IDEA TO COMPLETION FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 7

FLEXIBLE SOLUTIONS FOR YOUR REQUIREMENTS You decide on the degree of automation. From the Feige modular assembly system you compile your semi-automatic drum lling system according to your individual requirements for the calibrated lling of drums. Accelerate your lling processes Individual container and pallet lling The three product lines of FEIGE The individual containers are positi- FILLING for semi-automatic drum oned below the lling valve, automa- lling offer you all the functions of tically lled with calibrated accuracy gravimetric llers, ranging from the and manually closed....

Open the catalog to page 8

SEMI-AUTOMATIC FILLING EQUIPMENT SLIM LINE JUST FILL Cost-effective ller Designed in well-proven FEIGE quality and accuracy Simple installation – easy use DRUM FILLER TYPE 9 With non-driven roller conveyor COMPACT LINE PLUG & FILL Pre-con gurated / pre-assembled compact lling station Stainless steel load cells / 255 product parameter sets Conveyors with up to three motors DRUM FILLING STATION TYPE 19 With driven roller conveyor for drum in-feed and out-feed ADVANCED LINE COMPLEX CONFIGURATION Large conveying systems for empty and lled containers Filling products or environment require...

Open the catalog to page 9

INCREASED INDIVIDUALISATION DUE TO SYSTEM EXTENSION your FEIGE FILLING system in accordance with your per- formance and product charac- offered by the versatile additi- onal modules. Increased Productivity ■ Drum holding device ■ Roller conveyor on weigh scale ■ Roller conveyor in the in-feed and out-feed area Simplified Handling ■ Fine fill via product file ■ Man. bunging and sealing station

Open the catalog to page 10

High Flexibility ■ Level controlled ascent ■ Filling valve principle and geometry ■ Base Height Adjustment ■ Product hose suspension Utmost Process Reliability ■ Reduced fill start Nitrogen blanketing ■ Overpressure bunging station Bunghole extraction ■ Pressure surges reduction FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 11

AUTOMATICALLY ACHIEVING HIGH-PERFORMANCE FILLING You want to start the automatic lling of your drums immediately subsequent to installation? The fully automatic drum llers and automatic units of the “Compact Line“ and “Advanced Line“ will satisfy this wish Automatically neatly lled Versatile options For fully automatic drum lling, you The Advanced Line is characterised can choose from two lines of drum by a multitude of functions which leave nothing to be desired. For the central exhaust of lling With the most simple design of the gases, designs with closed cabins Compact Line you ll...

Open the catalog to page 12

AUTOMATIC DRUM FILLERS COMPACT LINE AUTOMATIC DRUM FILLING MACHINE TYPE 31 Automatic orientation PLUG & FILL Pre-con gurated / pre-assembled compact lling machines Operated via touch screen AUTOMATIC DRUM FILLING MACHINE TYPE 32 Automatic de-bunging ADVANCED LINE COMPLEX CONFIGURATION Large conveying systems for empty and lled containers Operated via touch screen Filling products or environment require special features AUTOMATIC DRUM FILLING MACHINE TYPE 33 Automatic de-bunging and bunging AUTOMATIC DRUM FILLER TYPE 81/84/86 Automatic de-bunging, bunging and cap sealing Output up to 120...

Open the catalog to page 13

QUALITY AND PROCESS CONTROL The right „turn“ The high standards required by occu- The sealing cap as original plug is pational health, safety and environ- an important factor and a quality The correct and secure bunging of mental protection require a correct drums is one of the most important and reliable closing of the containers. Torque monitoring of the screw caps topics when it comes to automatic To be able to meet the correspon- The metal sealing cap is automati- lling. The FEIGE torque monitoring ding requirements, closing with cally fed to the system as concluding unit checks the...

Open the catalog to page 14All Feige Filling catalogs and technical brochures

-

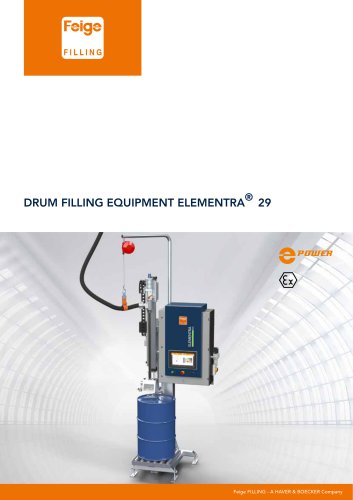

ELEMENTRA® 29

3 Pages

-

INTEGRA® 86

2 Pages

-

INTEGRA® 84

2 Pages

-

Imagebroschuere

24 Pages

-

Our Product range

2 Pages

-

Time to chain

3 Pages

-

CAN FILLING

20 Pages

-

PAIL FILLING

20 Pages

-

PALLET FILLING

20 Pages

Archived catalogs

-

Sommer-Feige Brsochüre

4 Pages