Website:

Feige Filling

Website:

Feige Filling

Group: HAVER & BOECKER

Catalog excerpts

FEIGE FILLING – A MEMBER OF THE HAVER® GROUP

Open the catalog to page 1

HIGHEST EFFICIENCY IN CAN FILLING FEIGE Filling GmbH is a traditional German medium-sized company in Bad Oldesloe. Founded in Hamburg in 1972, the company has developed into the market and technology leader in the eld of lling technology by its innovative strength and open-mindedness. FEIGE Filling stands for gravimetric lling equipment for the lling of liquid and pasty products with calibrated accuracy. We have the suitable lling technology to meet your challenge Let us help you ll your cans Whenever cans need to be lled, the use of lling equipment is inevitable. The modular assembly...

Open the catalog to page 2

FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 3

SAFETY - ACCURACY - FLEXIBILITY Reproducible accuracy as well as a high degree of safety during product lling are fundamental requirements which have to be met by lling equipment that satises the highest quality standards. Filling - always with an eye on safety Measuring with calibrated accuracy With the FEIGE Filling lling valve, The FEIGE Filling weigh scale ter- you ll your liquid and viscous pro- minal is the heart of the equipment. ducts with a proportional or multi- Measuring the dosed lling volumes stage dosing system. The lling valve with calibrated accuracy is carried is...

Open the catalog to page 4

Safety Functions The filling valves are equipped with important safety functions such as: Closing / opening with compressed air Closing with spring force Relieved of product pressure Leakage monitoring of the sealing space Fill level check With minimum dead space 255 product files, expandable Protocol of weighing results and statistics Alphanumeric entry through prompting Storage of operation data Label printer Protocol printer Measuring device Load cell Mass flow meter FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 5

CONCENTRATED KNOW-HOW IN INTRALOGISTICS If you are planning a seamless overall concept of lling equipment with end packaging, palletising, conveying and marking technology, talking with the specialists of FEIGE Filling will certainly be of assistance. Turnkey complete solutions In the eld of lling, FEIGE Filling will Innovative factory and system design (FEIGE FACTORY DESIGN) project your complete turnkey equipYou would like to look at your new logistic tasks. The equipment requi- equipment long before it is imple- red by different industrial sectors for mented in your production hall?...

Open the catalog to page 6

FROM THE FIRST IDEA TO COMPLETION FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 7

VERSATILE SOLUTIONS FOR YOUR REQUIREMENTS You decide on the degree of automation. Compile your semi-automatic can lling system according to your individual requirements for the calibrated lling of cans for foaming, combustible or uncritical products from the FEIGE Filling modular system. Accelerate your lling processes Can lling and further options The individual containers are positi- The three can lling product lines of oned below the lling valve, automa- FEIGE Filling offer you all the func- tically lled with calibrated accuracy tions of a gravimetric ller, ranging and manually closed....

Open the catalog to page 8

SEMI-AUTOMATIC CAN FILLING SYSTEMS SLIM LINE JUST FILL CAN FILLER TYPE 4 ■ Designed in well-proven FEIGE quality and accuracy ■ Simple installation - easy use COMPACT LINE PLUG & FILL CAN FILLING STATION TYPE 14 ■ Pre-configured / pre-assembled compact filling station ■ Stainless steel load cells / 255 product parameter sets ■ Conveyors with up to three motors ADVANCED LINE COMPLEX CONFIGURATION CAN FILLING EQUIPMENT TYPE 24 ■ Large conveying systems for empty and filled containers ■ Filling products or environment require special features FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 9

MODULAR SYSTEM EXTENSIONS Ever more demanding just-in-time deliveries involve a high coordination effort and cost pressure for any company. This is why, starting from a sturdy basic design, the FEIGE Filling equipment offers you a large choice of system offer the best solution to your grow along with your custo- want to start and we will be ready to adapt the extensions Increased Productivity ■ Roller conveyor on scale ■ Roller conveyor in the in-feed Simplified Handling ■ Fine fill via product file ■ Product hose suspension ■ Manual capping station

Open the catalog to page 10

SEMI-AUTOMATIC CAN FILLING TECHNOLOGY High Flexibility ■ Level controlled ascent ■ Filling valve principle and geometry ■ Base height adjustment Utmost Reliability ■ Reduced fill start ■ Pressure surges reduction FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 11

HIGHLY INTEGRATED POWERFUL AUTOMATIC CAN You want a maximum in performance and availability? And at the same time, you want an automatic can lling system that is open to integrate your individual ideas of transport systems and storage technology? Then FEIGE Filling is the right address for you. Versatile options The Advanced Line is characterised compact can lling systems can be by a multitude of functions which selected from two different product leave nothing to be desired. The lines. These automatic systems are integrated push-bar chain conveyor, equipped with specic characteristics...

Open the catalog to page 12

FULLY AUTOMATIC CAN FILLING TECHNOLOGY COMPACT LINE PLUG & FILL Pre-congured / pre-assembled compact lling machines Operated via touch screen AUTOMATIC CAN FILLING MACHINE TYPE 64 De-capping and dust cap removal Pre- and nal lling and capping ADVANCED LINE COMPLEX CONFIGURATION Large conveying systems for empty and lled containers Operated via touch screen Filling products or environment require special features AUTOMATIC CAN FILLER TYPE 600 Automatic opening , pre- and nal lling and capping Up to 4 lling units FEIGE FILLING - A MEMBER OF THE HAVER® GROUP

Open the catalog to page 13

HIGH QUALITY AND RELIABILITY Closing cans with a reliable process Accurate feed of caps Torque monitoring of the screw caps Before the cans are closed with screw The high standards required by caps or plugs, it is necessary to feed The correct and secure bunging occupational health and safety and them separately to the bunging head. environmental protection require a A tool which contributes to a further important topics when it comes to correct closing of the containers. The automation of the process is also automatic lling. The FEIGE torque FEIGE Filling capper supports you available for...

Open the catalog to page 14All Feige Filling catalogs and technical brochures

-

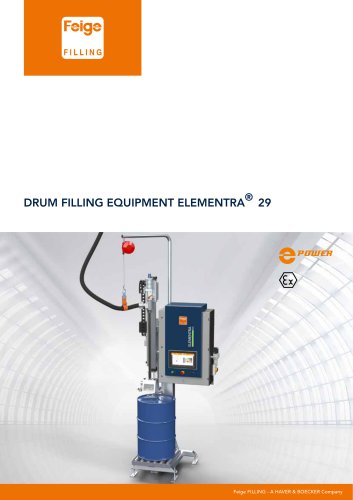

ELEMENTRA® 29

3 Pages

-

INTEGRA® 86

2 Pages

-

INTEGRA® 84

2 Pages

-

Imagebroschuere

24 Pages

-

Our Product range

2 Pages

-

Time to chain

3 Pages

-

PAIL FILLING

20 Pages

-

PALLET FILLING

20 Pages

-

DRUM FILLING

20 Pages

Archived catalogs

-

Sommer-Feige Brsochüre

4 Pages