Catalog excerpts

AUTOMATIC DRUM FILLING MACHINE TYPE 32 The CompactLine drum filling machine type 32 with two stations working in parallel is designed for the fully automatic and calibrated filling of drums. The drums are automatically positioned and de-bunged. At the same time, an open drum is filled in the filling station. A chain conveyor moves the drum in single cycle through the filling machine and feeds them to the working stations. Essential accessories are drip collecting, gas exhaust, even directly at the bunghole, overflow signals, collecting basin, earthing device, inert gas purging via double jacket filling lance, base height adjustment for drum heights between 810 mm and 970 mm and devices for manual drum closing. The benefits Compact ready-to-use machine which can control one roller conveyor each in the in-feed and out-feed area Stainless steel and acid protection design available Touch panel as operating interface with integrated weigh scale terminal and monitoring 255 product files Tare check, flow rate control, fill time monitoring Below-surface filling with lance raise by weight Product hose with direct filling valve connection ATEX design possible. If no de-bunging tool is installed, drum inertising is possible in the positioning station. TECHNICAL DATA | DESIGN Type 32.1-0-P0n Automatic drum filling machine, below-surface mode, for liquids which produce foam or gas during filling As above, additionally with de-bunging and plug dropping onto the drum head Types as above, additionally ATEX compliant for the use in hazardous area (zone 1) Types as above, but with below-bunghole filling for uncritical liquids

Open the catalog to page 1

FEOD-PB-32-en-1215, Printed in Germany ©FEIGE FILLING. Jede Art von Vervielfaltigung, auch auszugsweise, nur mit Genehmigung TECHNICAL DATA Electric design 3x400V/N/PE/50Hz, input power approx. 3 kVA ATEX design II 2G c IIB T3 Air consumption 60 Nl/cycle, incl. de-bunging 110 Nl/cycle for below-surface filling 40 Nl/cycle, incl. de-bunging 80 Nl/cycle for below-bunghole filling Weight 750 kg, with de-bunging tool 850 kg Weighing range, approved for verification 30 to 300 kg, increments 0.1kg Nominal output approx. 60 drums/h referred to 7l/s in coarse fill; for legal...

Open the catalog to page 2All Feige Filling catalogs and technical brochures

-

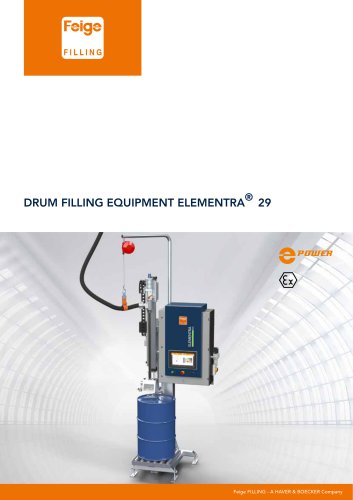

ELEMENTRA® 29

3 Pages

-

INTEGRA® 86

2 Pages

-

INTEGRA® 84

2 Pages

-

Imagebroschuere

24 Pages

-

Our Product range

2 Pages

-

Time to chain

3 Pages

-

CAN FILLING

20 Pages

-

PAIL FILLING

20 Pages

-

PALLET FILLING

20 Pages

-

DRUM FILLING

20 Pages

Archived catalogs

-

Sommer-Feige Brsochüre

4 Pages