Website:

Federal-Mogul Deva GmbH

Website:

Federal-Mogul Deva GmbH

Group: Tenneco Group

Catalog excerpts

Technical manual deva.de | Maintenance-free, self-lubricating sliding bear

Open the catalog to page 1

Your challenges are our fascination. Self-lubricating sliding bearings Contemporary designs pose a major challenge to modern sliding materials. Maintenance-free operation is often expected even under difcult operating conditions with extremely high loads. Constant cost pressure forces increasing availability of machines and systems, even though no restrictions can be accepted with regard to their reliability. With maintenance-free, self-lubricating high-performance sliding materials from the DEVA® product range, it is now possible to implement sliding bearing concepts that operate reliably...

Open the catalog to page 2

Of course maintenance-free. Sliding bearings from DEVA . Technical manual deva.metal® Material properties 2 Sliding bearing materials Shipbuilding and offshore industry Hydro-Civil Engineering Onshore and offshore wind turbines Bridges and steel construction Railway vehicles Mechanical engineering Injection molding and tire molding Agricultural and construction machines Mating materials Food and packaging machines Load cases Cylindrical sliding bearings 6.1 Recommended standard dimensions – cylindrical bushings 6.2 Recommended standard dimensions – flanged bushings 6.3 Fits and surfaces...

Open the catalog to page 3

deva.metal® sliding bearings Material properties Maintenance-free and self-lubricating sintered sliding materials deva.metal® is a high performance dry sliding bearing material. The powder metallurgically produced deva.metal® system is based on four main groups – bronze, iron, nickel and stainless steel. These contain solid lubricants, like graphite, which are uniformly embedded in the metal structure. As a material produced by powder metallurgy, deva.metal® is not ductile. However, the special sintering processes enable a very high physical resistance, especially under pressure load. The...

Open the catalog to page 4

deva.metal® sliding bearings Sliding bearing materials The continuous micro-wear ensures that new lubricant is fed into the system. This results in a maintenance-free operation in many applications. 2.1 Microstructure and texture The composition of the metallic structure determines the physical, mechanical and chemical properties of an alloy and is therefore the basis for the selection of materials for a specific application. There are four main groups, bronze-, iron-, nickel- and stainless steel-based. • Graphite – C • Molybdenum disulphide – MoS2 • Manganese sulphide – MnS Graphite is the...

Open the catalog to page 5

2.2 Overview of selected materials The deva.metal® sliding bearing family consists of more than 60 alloy variants. An overview of the common alloys is shown in table 2.2.1. Our application engineers will be pleased to select the most suitable alloy for your application. The standard temperature range of bronze materials is up to + 150 °C. In order to ensure the dimensional stability of bronze alloys in continuous operation even at higher temperatures, the material can be subjected to an additional heat treatment. The upper operating temperature limit is then + 350 °C. At operating...

Open the catalog to page 6

deva.metal® alloy Scheme material selection deva.metal® Typical applications of individual deva.metal® alloys 2.3 Material selection The following is a decision-making aid for the selection of the most appropriate deva.metal® alloys under certain operating conditions. Highly wear resistant Rolling Mills / Smelter Industry When high abrasiveness occurs Oven construction Hydraulic steelwork High static load, corrosion resistant Rolling Mills / Smelter Industry, Brakes Very good braking properties Heavy industry High load / abrasivity Steam and gas turbines, incinerators High abrasion...

Open the catalog to page 7

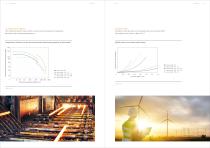

2.4 Temperature influence The maximum specific load to which a deva.metal® bearing can be subjected, decreases with increasing temperature. 2.5 Specific wear The effect of the pU value on the specific wear rate of deva.metal® Alloy systems are shown in Figure 2.5.1.. Temperature influence on the static permanent load bearing capacity of deva.metal® Specific wear rate of deva.metal® alloys Specific wear rate [µm/Rkm] Static permanent load bearing capacity [MPa] Constant operating tempera

Open the catalog to page 8

deva.metal® sliding bearings deva.metal® sliding bearings Load cases Environmental protection and production safety We attach great importance to qualitative, environmentally conscious and safe production. We are committed to this through the application of a variety of internationally recognized standards for quality assurance, emission control and workplace safety. The four cases of bearing load DEVA® differentiates between four load cases. We do this to take into account the fatigue influences under dynamic load. The percentage values refer to the limit values given in the material data...

Open the catalog to page 9

deva.metal® sliding bearings Roughness and surface finish The deva.metal® sliding materials require the use of a mating material with a minimum hardness of 180 HB. If the bearing is additionally lubricated, hardness values of >130 HB can also be permitted. In case of high sliding distances or abrasion from the environment, a hardened surface of 35 HRC / 45 HRC should be used. The surface roughness when using deva.metal® is ideally Ra = 0.2 bis 0.8 μm produced by grinding. Depending on the operating conditions, greater surface roughness can also be accepted. Suggested materials The following...

Open the catalog to page 10

deva.metal® sliding bearings Cylindrical sliding bearings Dimension table Selection of the min. outer diameter D2 min and the maximum producible length Bmax of deva.metal® bushings depending on the specific surface load p and the alloy. For longer bearings, a multi-part solution of 2 or more bushings is possible Recommendation Recommended and producible tolerances see page 22 and 23 6.1 Recommended standard dimensions – cylindrical bushings The maximum available inner diameter for cylindrical sliding bearing bushes made of deva.metal® is 560 mm and the outer diameter 600 mm. Table 6.1.1...

Open the catalog to page 11All Federal-Mogul Deva GmbH catalogs and technical brochures

-

deva_glide_EN

17 Pages

-

deva_tex_EN

32 Pages

-

deva_bm_EN

32 Pages

Archived catalogs

-

DEVA Spherical Bearings

32 Pages

-

deva.metal technical handbook

24 Pages

-

deva.bm technical handbook

24 Pages

-

deva.glide technical handbook

20 Pages

-

deva.tex technical Handbbok

20 Pages

-

Product Range

12 Pages