Catalog excerpts

Always a cut above - since 1870 Horizontal CNC contour cutting centers Type I C 69

Open the catalog to page 1

Monika Marcinkowski Purchase René Matt Purchase Manager Fecken-Kirfel produces precise and efficient cutting machines to process a wide variety of different plastics, rubber and similar materials. Founded in 1870, this family-owned company today leads the way on technology and quality in its field worldwide. Using its large pool of engineering knowledge and expertise, FeckenKirfel works together with customers to keep on developing its range of machines further. We produce 100 % of our cutting machines at our main base in Aachen, Germany. Founded in 1870 Independent family-owned business...

Open the catalog to page 2

HELLO AND WELCOME! With an outstanding level of accuracy and a fast cutting speed, the horizontal CNC contour cutting centers offer maximum productivity combined with the highest quality standards. This is real a competitive advantage when it comes to the production of upholstered furniture and mattresses, and technical foams or foams with a high bulk density. Fecken-Kirfel‘s C 6x series come with two different types of knife: The C 66/C 67 models use a rotating band knife, while the C 68/C 69 models cut with an oscillating knife. The C 67 and C 69 are suitable for integration into a...

Open the catalog to page 3

Technical data Cutting speed 40 m/min 40 m/min 15 m/min 70 m/min (optional) 70 m/min (optional) Band knife Twist angle Grinding device Central knife guidance Hold-down device Autom. turning table HORIZONTAL CONTOUR CUTTING CENTERS C 6x Fecken-Kirfel‘s horizontal contour cutting centers are available with a smooth ground knife (C 66/C 67) or oscillating toothed knife (C 68/C 69). Stand-alone solutions are available (C 66/C 68), as are models with automatic loading or unloading (C 67/C 69), which are ideal for integration into a cutting line. Area of application: Cutting contours and trimming...

Open the catalog to page 4

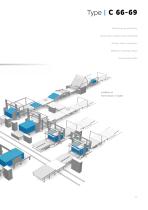

Type | C 66-69 The cutting process: If the contour cutting centers are equipped with a rotating material table, the loaded cutting program can be completed in just a few steps. 3. Material table turns 90° 4. Contour trimmed to size through vertical cross sections CUSTOMIZED CUTTING PROGRAMS – MORE SIMPLE, FLEXIBLE AND ECONOMICAL Creating a program: Cutting programs created in other FK contour cutting centers can be copied over. You can create new programs in a separate CADPC, which is Window-based like the CNC computer in the machine. Creating a cutting contour: You can create cutting...

Open the catalog to page 5

Johny Schulz Herbert Kamphausen Construction group leaders SHARP AT ALL TIMES – THE ROTATING BAND KNIFE Minimum processing times for hard materials: Thanks to a movable cutting unit and the latest in drive technology, the machine offers exceptional performance, ensuring high cutting speeds can be reached. Coupled with a high-precision grinding device, this ensures quick processing times are guaranteed. Material fixed in the best way possible: The machine is equipped with a hold-down device consisting of plates to ensure that the material is positioned perfectly and that processing is fast...

Open the catalog to page 6

Type | C 66 and C 67 With rotating band knife Adjustable central knife guidance Excellent option for hard materials Maximum cutting speed Minimal space requirements C 67 with 2900 mm working width C 67 ready for integration into a cutting line

Open the catalog to page 7

Axel Wynands General Manager Sales Stefan Lennartz Group leader, Construction OPTIMAL PRECISION AT ALL TIMES – THE OSCILLATING KNIFE Outstanding cutting accuracy: The oscillation technology is ideal for cutting technical materials, as well as contours with sharp edges or small radii with low tolerances. Very easy to maintain: Fecken-Kirfel uses the latest in servo drives for this new oscillation principle. Two synchronized motors generate the oscillating motion of the knife. This means that no gear unit and connecting components, such as steel ropes and deflection pulleys, are required....

Open the catalog to page 8

Type | C 68 and C 69 With oscillating knife Outstanding cutting accuracy Easy maintenance Minimal space requirements C 69 ready for integration into a cutting line

Open the catalog to page 9

Michael Frings Parts production Michael Bürger Foreman, Parts production Your blocks can be processed from the long block instead of from the short block – a sensible and efficient way of working. The long block is cut to its final dimensions directly. The advantage: it saves you the trimming work. THE FULLY AUTOMATIC CUTTING LINE When you integrate the C 67 and C 69 into a cutting line, you combine maximum speed with outstanding accuracy, and thus increase productivity while maintaining the highest quality standards. Set up perfectly for integration: Both contour centers feature powered...

Open the catalog to page 10

Type | C 66-69 Maximum productivity Automatic loading and unloading Driven roller conveyors Different cutting orders Unmanned shifts Installed at Torres Espic in Spain

Open the catalog to page 11

Postfach 10 08 54 | 52008 Aachen | Germany | Tel. +49 241 18202-0 | Fax +49 241 18202-13 | info@fecken-kirfel.de | www.fecken-kirfel.de Fecken-Kirfel America, Inc. affiliated to Fecken-Kirfel GmbH & Co. KG | Aachen | Germany 6 Leighton Place | Mahwah, N.J. 07430 | USA | Phone +1 201 891-5530 | Fax +1 201 891-0129 | info@fk-am.com Fecken-Kirfel GmbH & Co. KG | Prager Ring 1 - 15 | 52070 Aachen | Germany

Open the catalog to page 12All Fecken-Kirfel GmbH & Co. KG catalogs and technical brochures

-

Type T

8 Pages

-

T6 and T8

12 Pages

-

Type V

8 Pages

-

Type W/H

8 Pages

-

H 24 T

2 Pages

-

H24 E H31/H32

8 Pages

-

H 24 A/H 24 F

6 Pages

-

Type G

6 Pages

-

F 62

8 Pages

-

D 5

2 Pages

-

D 31

2 Pages

-

D 21

8 Pages

-

Cutting Line

4 Pages

-

CF 67

2 Pages

-

C55/C56/C57

8 Pages

-

A 7

6 Pages