Catalog excerpts

Fecken Kirfel

Open the catalog to page 1

Fecken Kirfel C 67 Horizontal CNC Contour Cutting Center high cutting speed and excellent cutting precision (see graphic and table page 5) I optional turntable I automatic adjustment of the central knife guidance I three phases of creating cutting programs: - Creation of the contour - Nesting of the contours - Creation of the cutting line (routing) I T 8 Blocking machine precisely and economically cutting-off, trimming or dividing into short or long blocks I bandknife ground on both sides (twistable by 90°) => minimization of unproductive empty runs I often used in complex cutting lines,...

Open the catalog to page 2

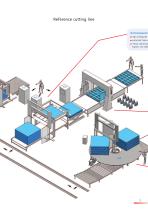

Reference cutting line automatic take-a "block optimizat (option, see table

Open the catalog to page 3

Fecken Kirfel Horizontal Splitter W 22/ H 52 (option): Block optimization software Example requirements: Splitting and Stacking Machine tension allowing a sheet of 1,5 mm (0,06“) away conveyor for multiple sheets (option) tion" for maximum yields of the block e right hand) nominal layer thickness: max. Tolerance: minimum remnant layer: available block height: Without “Block optimization” nominal layer thickness: 25 mm 1“ With “Block optimization” optimum layer thickness: 23,6 mm 0.94“ remnant layer: 12 mm 0.5“ material savings: 7.32 % F 62 Vertical CNC Contour Cutting Center I flexible and...

Open the catalog to page 4

Fecken Kirfel Horizontal CNC Contour Cutting Center C 67 Comparison of acceleration and cutting speed with a competitor’s machine On CNC Machines high acceleration is more important than a high maximum cutting speed. A detailed analysis proves this as shown in the diagram below illustrating the speed development while cutting a contour. Blue line: Fecken-Kirfel C 67 high acceleration, highest cutting speed 70 m/min (230'/min), cutting time: 20 s Red line: Competitor’s machine, standard acceleration, highest cutting speed 60 m/min (197'/min), cutting time: 24 s Comparison of cutting times at...

Open the catalog to page 5

■ used behind profile cutting machines or any kind of conveyor systems ■ convoluted layers up to a maximum block length of 2400 mm (55.118") are placed onto pallets or conveyors Airlift table ■ positions sheets for convoluting D 31 Profile cutting machine (convoluter) ■ reinforced execution for a thickness up to 300 mm (12") ■ bondstrip coated on both sides ■ integrated infeed and outfeed conveyors Automatic de-stacking device ■ feeds individual sheets Fecken-Kirfel GmbH & Co. KG Maschinenfabrik ■ Prager Ring 1-15- D-52070 Aachen ■ Germany ■ www.fecken-kirfel.de Postfach 100854 ■ D-52008...

Open the catalog to page 6All Fecken-Kirfel GmbH & Co. KG catalogs and technical brochures

-

Type T

8 Pages

-

T6 and T8

12 Pages

-

Type V

8 Pages

-

Type W/H

8 Pages

-

H 24 T

2 Pages

-

H24 E H31/H32

8 Pages

-

H 24 A/H 24 F

6 Pages

-

Type G

6 Pages

-

F 62

8 Pages

-

D 5

2 Pages

-

D 31

2 Pages

-

D 21

8 Pages

-

Cutting Line

4 Pages

-

CF 67

2 Pages

-

C55/C56/C57

8 Pages