Website:

FBF Italia SRL

Website:

FBF Italia SRL

Catalog excerpts

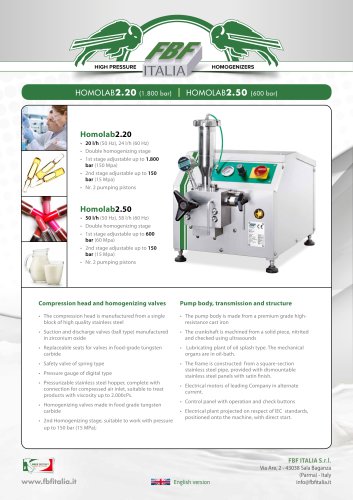

HIGH PRESSURE ITALIA HOMOGENIZERS Homolab2.20 • 20 l/h (50 Hz), 24 l/h (60 Hz) • Double homogenizing stage • 1st stage adjustable up to 1.800 bar (150 Mpa) • 2nd stage adjustable up to 150 bar (15 Mpa) • Nr. 2 pumping pistons Homolab2.50 • 50 l/h (50 Hz), 58 l/h (60 Hz) • Double homogenizing stage • 1st stage adjustable up to 600 bar (60 Mpa) • 2nd stage adjustable up to 150 bar (15 Mpa) • Nr. 2 pumping pistons Compression head and homogenizing valves • The compression head is manufactured from a single block of high quality stainless steel • Suction and discharge valves (ball type) manufactured in zirconium oxide • Replaceable seats for valves in food-grade tungsten carbide • Safety valve of spring type • Pressure gauge of digital type • Pressurizable stainless steel hopper, complete with connection for compressed air inlet, suitable to treat products with viscosity up to 2.000cPs. • Homogenizing valves made in food grade tungsten carbide • 2nd Homogenizing stage, suitable to work with pressure up to 150 bar (15 MPa); Pump body, transmission and structure • The pump body is made from a premium grade high-resistance cast iron • The crankshaft is machined from a solid piece, nitrited and checked using ultrasounds • Lubricating plant of oil splash type. The mechanical organs are in oil-bath. • The frame is constructed from a square-section stainless steel pipe, provided with dismountable stainless steel panels with satin finish. • Electrical motors of leading Company in alternate current. • Control panel with operation and check buttons • Electrical plant projected on respect of IEC standards, positioned onto the machine, with direct start. VJ FBF ITALIA S.r.l. Via Are, 2 - 43038 Sala Baganza (Parma) - Italy www.fbfitalia.it L-I-- English version

Open the catalog to page 1

The homogenizers Homolab2.20 and Homolab2.50 are laboratory homogenizers with an easy installation (no need of water for cooling of pistons) and use (manual adjustment of homogenizing pressure via hand wheels). Decision to equip these homogenizers with nr. 2 pistons is very important to grant valid results as the ones that can be obtained with bigger machines that can be used in an industrial process. The machine is complete with double homogenizing stage and with pressurizable hopper (with capacity of 0.8 or 1.6 liters); the only option is the hopper with a jacket for hot water (hot water...

Open the catalog to page 2All FBF Italia SRL catalogs and technical brochures

-

FBF7 Series

2 Pages

-

FBF8 Series

2 Pages

-

FBF9 Series

2 Pages

-

FBF0 SERIES

2 Pages

-

Microlab 400

2 Pages

-

HIGH PRESSURE HOMOGENIZERS

2 Pages