Website:

Farley Laserlab

Website:

Farley Laserlab

Group: Wuhan HGLaser Engineering Co.,Ltd.

Catalog excerpts

HGTECH Tire Mold Laser Cleaning Intelligent Solutions Innovation Fuels a Better World

Open the catalog to page 1

Pioneer and leader of aser industrial application in China The first domestic listed company with laser as its main business (stock code 000988) The first company in China and the second company in the world to focus on laser intelligent equipment as the core solutions with a full industry chain layout. Innovation Fuels Better Wo

Open the catalog to page 2

INDUSTRIAL LAYOUT China First World Second Comprehensive intelligent manufacturing system HGTECH Fiber-optic laser YAG UV laser and ultrafast laser Direct semiconductor laser • Wuhan Raycus Fiber Laser Technologies Co., Ltd. • Wuhan Huaray Precision Laser Co.,Ltd. • Suzhou Everbright Photonics Co., Ltd. Measuring & Testing System Automated Processing System • Suzhou HG Automation Technology Co., Ltd. • Shenzhen Measurement Technology Co.,Ltd. Laser Source Laser Intelligent Equipment Measurement & Automated Production Line Smart Factory Measuring Intelligent Manufacturing Information System...

Open the catalog to page 3

Laser Intelligent Equipment & Automated Production Line I TP12052F<12052F 4 Trucks (Side Hanging) Heavy Load Laser Tube Cutting Machine I TP12036M<12036M 3 Trucks (Side Hanging) Heavy Load Laser Tube Cutting Machine I TP10032W<10032W 3 Trucks (horizontal) Heavy Load Laser Tube Cutting Machine I TP6322<6322 2 Trucks (horizontal) Heavy Load Laser Tube Cutting Machine I GF3015_TUBE Tube-Plate Integrated Laser Cutting Machine I AUTOBOT3015 3D 5 Axis Laser Cutting Machine for Automobile Thermoforming Parts I SF 3D 5 Axis Laser Cutting Machine I SF3015E 3D 5 Axis Laser Cutting Machine I...

Open the catalog to page 4

Laser Welding BIW Laser Welding Laser Cleaning Robot Flexible Laser Cutting and Welding System Battery Tray Laser Welding System Robot Flexible Laser Cutting and Welding System Automobile Bumper Laser Punching and Welding System Flexible Non-metal Laser Cutting System Automobile Dash Board Laser Weakening for Safety Airbag Robot Flexible Laser Cutting and Welding System Online Tube Laser Welding System Large Scale Metal Sheet Laser Welding System I Full Automatic CNC Laser Tailor Welding Production Line I Full Automatic Welding Production Line for Automobile Transmission Parts I Large Scale...

Open the catalog to page 5

Integration of automation, information technology, and intelligence with manufacturing industry. Automated machining system . Automation production line for 3C products ' Automated assembly line for 4G high Automation production line for 5G / communication products , Automation production line for optical modules I Personalized information and packaging production line for power supplies / Automated assembly line for contactors Automated production line for lithium-ion ' batteries industry I Automated production line for photovoltaic industry / Automated production line for hydrogen energy...

Open the catalog to page 6

SMART MANUFACTURING We have built and are building over 30 automated, information-based, and intelligent smart factories to create benchmark enterprises. We provide a complete Lesso Group's Intelligent Factory in the Pipe Fitting Industry Zoomlion Heavy Industry Intelligent Manufacturing Plant in the Construction Machinery Industry solution for the smart factory. Planning and design, simulation MES system HG-PMS system WMS system Visual BI System integration Warehouse and logistics, etc. Wuhan Shipbuilding Heavy Industry Group/ Gansu Borui Smart Bridge Shanxi Taizhong intelligent factory in...

Open the catalog to page 7

Hamburg, Germany ■ Intelligent Manufacturing Research Center Toronto, Canada R&D center of ultrafast laser 10 25 Overseas R&D Center Overseas Subsidiary Foreign Service Center Silicon Valley© q ©Poland Germany Italy© ©Turkey Bulgaria Egypt China Wuhan Wuhan, China Pakistan National Engineering Research Center Laboratory of Laser National Enterprise Technology Center The United states Silicon Valley Laser application research and development center Houston High power research and development center Chicago High power research and development center Melbourne, Australia High power laser...

Open the catalog to page 8

Principles and Advantages of Laser Cleaning

Open the catalog to page 9

Degreasing the surface of stainless steelwheel hub Removing welding oxide layerfrom stainless steel • The beam energy emitted by the laser is absorbed by thepollution layer on the surface to be treated; • The absorption of large energy forms a rapidly expandingplasma (highly ionized unstable gas), generate shock wave; • The shock wave makes the pollutants evaporate or peel offinstantaneously. • With correct laser parameters and optimal wavelength, thebase materialwill not be damaged or melted.

Open the catalog to page 10

Principles and Advantages of Laser Cleaning Technical Advantages Mechanical Cleaning • Low cleaning effect • Severe workpiece damage • labor-intensive Laser cleaning will become the first-choice cleaning method in the future Technical Advantages • Accurate and controllable: cleaning area and thickness are accurate and controllable • poor consistency • Uniform cleaning quality: uniform and consistent throughout the lifetime of the laser Chemical Grinding • Intelligence: Easy to detect and control, intelligent process • Environmental Pollution • No damage: only remove surface contaminants •...

Open the catalog to page 11

Laser Cleaning of Tire Mold Intelligent Solutions

Open the catalog to page 12

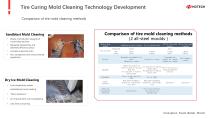

Tire Curing Mold Cleaning Technology Development I “ ~ “* ' Trends in Tire Molds 1. Tire mold material: Aluminum molds have advantages such as faster heating, lighter weight, simpler machining, and longer service life; 2. The mold pattern appearance design aims to achieve low rolling resistance, high performance, and a beautiful appearance. The pattern details become more numerous, and the pattern blocks become smaller and fragmented; 3. High-end tires: such as the velvet high-end pattern series from Prinx Chengshan, the tire sidewalls are as soft and delicate as velvet, beautiful and...

Open the catalog to page 13

Comparison of tire mold cleaning methods Sandblast Mold Cleaning • Waste of production capacity of vulcanizing machine • Repeated disassembly and assembly affects accuracy • Increase enterprise costs • Non compliance with environmental regulations Comparison of tire mold cleaning methods (2 all-steel moulds ) Dry Ice Mold Cleaning • Low temperature causes embrittlement and cracking • "Micro explosion" • An improvement over sandblasting • Less time consuming Innovation Fuels Better World

Open the catalog to page 14All Farley Laserlab catalogs and technical brochures

-

Desktop Laser Marking

1 Pages

-

Press Brake

1 Pages

-

CNC Bending Machine

6 Pages

-

PCB Laser Marking Sample

2 Pages

-

Welding Serials Products

3 Pages

-

LWF1000-HLW

2 Pages

-

CO2 Laser Marking sampe

2 Pages

-

MARVEL Series

2 Pages

-

Flying CO2 Laser Marking

1 Pages

-

Flying Fiber Laser Marking

1 Pages

-

Laser Marking Sample

2 Pages

-

Green Laser Marking Machine

2 Pages

-

UV Laser Marking Sample

2 Pages

-

UV Laser Marking Machine

2 Pages

-

3D Marking Sample

3 Pages

-

3D Laser Marking Machine

3 Pages

-

PCB LASER MARKING MACHINE

3 Pages

-

LASER BLANKING LINE

5 Pages

-

Marvel12000-3015

1 Pages

-

Laser Cutting Sample

2 Pages

-

Fiber Laser Cutter

13 Pages

-

3015 Fiber Laser Cutting Machine

19 Pages

-

Tube Laser Cutting

2 Pages

-

Laser Cutting and Engraving

21 Pages

-

Handheld Laser Welder

2 Pages

-

Fiber Laser Cutting Machine

2 Pages

-

Fiber Welding Machine

7 Pages

-

3D Laser Cutting

4 Pages

-

Handheld Laser Welder

2 Pages

-

SMT PCB Laser Solution

10 Pages

-

20000W Laser Cutting Machine

2 Pages

-

PCB Laser Marking

9 Pages

-

FPC Laser Cutting

1 Pages

-

Fiber Laser Welding System

2 Pages

-

Flying laser marking machine

8 Pages

-

laser cleaning machine

2 Pages

-

PCB Laser Marking Solution

7 Pages

-

PCB Laser Marking Machine

6 Pages

-

GF3015 Laser Cutting Machine

1 Pages

-

Farley Laserlab PROFILE PLUS

4 Pages