Website:

Farley Laserlab

Website:

Farley Laserlab

Group: Wuhan HGLaser Engineering Co.,Ltd.

Catalog excerpts

FIBER LASER CUTTING SYSTEM Innovation Fuels a Better World HG STAR TECHNOLOGY CO.,Ltd.

Open the catalog to page 1

HEAD OFFICE: HGTECH Precision micro-nano processing Intelligent Equipment Industry District, 3rd Keji Road, Gaoxin Avenue, East Lake Hi-Tech Development zone, Wuhan, P.R.China 430223 TEL: +86 27 87180253 FAX: +86 27 87180210 Email: info@hglaser.com

Open the catalog to page 2

1. Technical Specification Machine Model Laser Source Transmission system Gantry double- drive structure Servo Motor Laser Cutting Head Position Accuracy (X and Y axis) Reposition Accuracy (X and Y axis) Lubrication system Power Supply Requirement Machine weight Appearance size Working environment HEAD OFFICE: HGTECH Precision micro-nano processing Intelligent Equipment Industry District, 3rd Keji Road, Gaoxin Avenue, East Lake Hi-Tech Development zone, Wuhan, P.R.China 430223 TEL: +86 27 87180253 FAX: +86 27 87180210 Email: inf

Open the catalog to page 3

2. Machine configuration NO. Model SMART3015-1000 Fiber laser cuttingmachine 1 set W (3000mm*1500mm) Laser generator Water chiller Special water chiller for 1 set fiber laser generator Laser head High accuracy professional 1 set fiber laser head Swiss Brand Raytools Auto Focus Control system Japan Fuji servo motor X axis 750w 7 Driving system High speed servo motor Japan Shimpo Electric components Germany LEITESEN HEAD OFFICE: HGTECH Precision micro-nano processing Intelligent Equipment Industry District, 3rd Keji Road, Gaoxin Avenue, East Lake Hi-Tech Development zone, Wuhan, P.R.China...

Open the catalog to page 4

Welding Machine Bed High Rigidity Stable and High Accuracy Easy to reduce stress,20 years’ no deformation High accuracy laser head: Almost zero fault; Anti-collision design; height adjustment high sensitivity. support three-grade perforate support fly-cutting,leapfrog. automatic focus adjustment, JAPAN Fuji servo high speed srvo motor Effectively decrease the speed of beam, make cutting and machine more stable to keep machine life long work. ITALY PEK rail/LEITESEN Rack HEAD OFFICE: HGTECH Precision micro-nano processing Intelligent Equipment Industry District, 3rd Keji Road,...

Open the catalog to page 5

Japan SMC proportional valves French Schneider Components Machine tool precision: Guide the installation process, the whole with a laser collimator calibration accuracy, make sure that the whole wide positioning accuracy to 0.05 mm; The machine after the installation and use it to compensate the precision of laser interferometer. Ensure the accuracy of machine tool; The precision data collected by laser interferometer are recorded in the numerical control system for precision compensation in electrical debugging. Fiber Laser Source 1KW The laser source is Dedicated developed by HGTECH...

Open the catalog to page 6

Equipment Working Conditions and Buyer Assistance The Working Conditions: For long-term 24-hour stable operation of the laser cutting machine, it has following requirements in terms of water, electricity, gas, working environment, foundation. Cooling water Deionized Water (conductivity <10μS/cm) 1.2m3/min Power supply Grounding / Earthing Machine tool Power Supply Name Laser source The total installed capacity is not less than 35 KVA. The corrosion inhibitors are needed to add in the cooling water (user scope) The air dryer and precision filters is required, This equipment is optional Laser...

Open the catalog to page 7

5. Equipment warranty period: The whole machine warranty is One Year. Laser source Two Years. Please note: Fiber Cable, Optical Lens, consumables and accessories are not covered under warranty. The warranty starts from the date of qualified acceptance at the user’s plant, and in any event no later than 90 days from the date of intimation of readiness of machine by the Seller. HEAD OFFICE: HGTECH Precision micro-nano processing Intelligent Equipment Industry District, 3rd Keji Road, Gaoxin Avenue, East Lake Hi-Tech Development zone, Wuhan, P.R.China 430223 TEL: +86 27 87180253 FAX: +86 27...

Open the catalog to page 8All Farley Laserlab catalogs and technical brochures

-

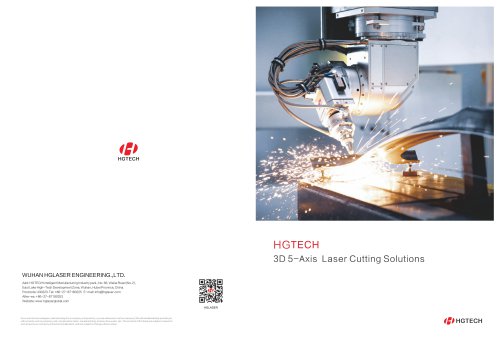

3D Laser cutting machine

14 Pages

-

Hand Laser Engraving Machine

6 Pages

-

Tire Mold Laser Cleaning Machine

26 Pages

-

Desktop Laser Marking

1 Pages

-

Press Brake

1 Pages

-

CNC Bending Machine

6 Pages

-

PCB Laser Marking Sample

2 Pages

-

Welding Serials Products

3 Pages

-

LWF1000-HLW

2 Pages

-

CO2 Laser Marking sampe

2 Pages

-

MARVEL Series

2 Pages

-

Flying CO2 Laser Marking

1 Pages

-

Flying Fiber Laser Marking

1 Pages

-

Laser Marking Sample

2 Pages

-

Green Laser Marking Machine

2 Pages

-

UV Laser Marking Sample

2 Pages

-

UV Laser Marking Machine

2 Pages

-

3D Marking Sample

3 Pages

-

3D Laser Marking Machine

3 Pages

-

PCB LASER MARKING MACHINE

3 Pages

-

LASER BLANKING LINE

5 Pages

-

Marvel12000-3015

1 Pages

-

Laser Cutting Sample

2 Pages

-

Fiber Laser Cutter

13 Pages

-

3015 Fiber Laser Cutting Machine

19 Pages

-

Tube Laser Cutting

2 Pages

-

Laser Cutting and Engraving

21 Pages

-

Handheld Laser Welder

2 Pages

-

Fiber Laser Cutting Machine

2 Pages

-

Fiber Welding Machine

7 Pages

-

3D Laser Cutting

4 Pages

-

Handheld Laser Welder

2 Pages

-

SMT PCB Laser Solution

10 Pages

-

20000W Laser Cutting Machine

2 Pages

-

PCB Laser Marking

9 Pages

-

FPC Laser Cutting

1 Pages

-

Fiber Laser Welding System

2 Pages

-

Flying laser marking machine

8 Pages

-

laser cleaning machine

2 Pages

-

PCB Laser Marking Solution

7 Pages

-

PCB Laser Marking Machine

6 Pages

-

GF3015 Laser Cutting Machine

1 Pages

-

Farley Laserlab PROFILE PLUS

4 Pages