Catalog excerpts

THE FACTORY AUTOMATION COMPANY CNC Controls Product overview

Open the catalog to page 1

100% FANUC FANUC Laser Systems No. 1 in the world FANUC is the leading global manufacturer of factory automation, with more than 60 years experience in the development of computer numerical control equipment. It has more than 5,2 million CNC controls installed worldwide and satisfied customers in every corner of the globe. FANUC Drive Systems

Open the catalog to page 2

Highest quality – shortest processing time With more than 60 years‘ experience FANUC offers the widest range of CNC systems in the industry from best value controls with powerful functionality, to high-performance control systems for complex machines – all with fast programming and ease of use, guaranteeing the highest quality and short processing times. That‘s how we increase your productivity. More than years MTBF for 0i-D/F series Your advantages: • 100% FANUC quality • more than 60 years of experience • wide range of displays and panels • stand-alone CNCs • LCD mounted CNCs • highest...

Open the catalog to page 3

Flexible package solutions FANUC offers all major components for your CNC controlled machine: CNC controls, motors and amplifiers in a tailor made and easy to install package for your specific needs. All components are developed and manufactured in-house. The results are superior functional reliability and the highest levels of machine availability – with a mean time between failure of well over forty seven years*, contributing to extremely low cost of ownership. *for 0i-D/F series All components 100% FANUC quality

Open the catalog to page 4

CNC stand alone HSSB Ethernet Display-Bus Your advantages: Beta I/O Link i drives External measuring system PROFINET IO EtherNet/IP FL-net PROFIBUS DP DeviceNet CC-Link AS-i EtherCAT * Servo motor *(only Digital Servo Adapter - B) Unique flexibility Only FANUC offers you CNC controls in two general versions: LCD mounted as compact solution with less space consumption and less hardware or as highly flexible stand-alone solution. Your benefit: full flexibility for your machine design. Versatile field bus systems • FANUC I/O Link i • PROFINET IO • EtherNet/IP • FL-net • PROFIBUS DP • Modbus...

Open the catalog to page 5

High-performance CNC for complex machine tools Key features: • up to 48 axes, 16 spindle axes and 10 paths * • 5-axis machining • compound mill / turn or turn / mill machining • extended integrated preventive maintenance functions • integrated FANUC Dual Check Safety function • shop-floor programming via iHMI or MANUAL GUIDE i • collision control via 3D Interference Check • dynamic compensation functions for highest accuracy • High-Speed Smooth Tool Center Point 5-Axis Compensation • Learning Control / High-Speed-Cycle-Machining • integrated high-speed PMC • high speed cutting • iHMI...

Open the catalog to page 6

CNC designed for transfer lines Key features: • up to 20 axis, 4 spindle axis and 4 path • ready to use with integrated software package • simple axis setup • additional functions for simple customisation • up to 5 integrated high speed PMCs • integrated FANUC Dual Check Safety function Applications: • transfer lines • gantries • ultiple milling / m drilling stations CNC for motion control and various applications Key features: • up to 32 axis and 4 path • ready to use with integrated software package • integrated FANUC Dual Check Safety function • additional functions for simple...

Open the catalog to page 7

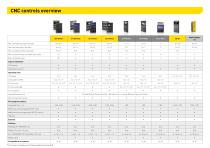

Max. feed axes total / per path Max. spindle axes total / per path Stand-alone version Max. controlled axes total / per path Max. simultaneously controlled axes / path Max. controlled paths Type of installation Operating units LCD panel Touch systems LCD panel for iHMI PC front-end Portable Manual Pulse Generator / iPendant and / or Handy Machine Operator‘s Panel Handheld control unit Machine operators panel Additional mass storage device CF-card Additional mass storage device HD-PC-version FANUC I/O-Link i / FL-net

Open the catalog to page 8

Dual Check Safety Smart Machine Control Nano Interpolation Nano Smoothing Fine Surface Technology Tool Functions / Tool Management System Tilted Working Plane / Tool Center Point Control Smooth simultaneous 5-axis machining Error Compensation / Volumetric Error Compensation

Open the catalog to page 9

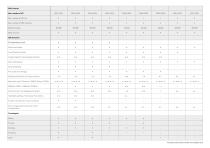

Configure your CNC Each FANUC CNC series offers a diverse range of panels and screen solutions. Your benefit: a wide variety of configuration options for every specific machining solution providing full flexibility for your ideas. The FANUC standard LCD display is available in 2 basic versions: LCD-mounted type embedded in the CNC, physically mounted directly behind the LCD panel or as a separate stand-alone display unit which is connected to the CNC using a fiber optics cable. Standard LCD displays are available in sizes from 8.4“ in diagonal up to 15“, with and without touch panel. LCD...

Open the catalog to page 10

FANUC iHMI - Simple. Efficient. Intuitive. FANUC iHMI has been designed to be extremely easy to use. Intuitive menu icons, high-visibility design and animated features take the head-scratching out of complex machining operations, making accessing even the most sophisticated programs and functionalities straightforward. Despite its more intuitive layout, users will nevertheless find that it provides a familiar FANUC user experience. CNC operation screen Simple Easy operation along process flow with integration of three screens: Various cycles • turning • milling • measurement Friendly Help...

Open the catalog to page 11

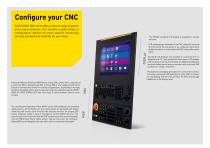

Tool Manager Uniform tool information management for machine Machine collision avoidance Uniform tool information management for machine Data logger Investigate cause of problem while machining Maintenance manager Observe CNC and machine parts and set alert for exchange time Servo viewer Measure and display various kinds of data Manual viewer Always refer to the machine’s manua

Open the catalog to page 12

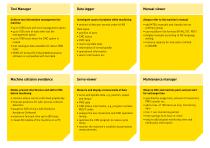

Tool Manager Data logger Manual viewer Uniform tool information management for machine Investigate cause of problem while machining Always refer to the machine’s manual • up to 1000 tools with tool management option • p to 1024 sets of tools with tool life u management option • p to 1000 tools when the CNC option is u invalid • ool catalogue data available for about 2000 t tools • VERICUT format (TLS file) CAM/simulation software is compatible with tool data • amount of data per second under 64 KB Data types: • position of axes • CNC status • PMC data • macro variable data • information of...

Open the catalog to page 13All FANUC Europe Corporation catalogs and technical brochures

-

R-30iB Plus

2 Pages

-

iRPickTool

7 Pages

-

MT-LINKi

5 Pages

-

FANUC LVC

2 Pages

-

Collaborative robots

13 Pages

-

Drive System

16 Pages

-

Integrated Laser System

7 Pages

-

Force Sensor

7 Pages

-

ROBOCUT

17 Pages

-

ROBODRILL

19 Pages

-

iHMI

4 Pages

-

iR Vision

9 Pages

-

FANUC Robots Brochure

56 Pages

-

R-2000iC/165F

1 Pages

-

CRX-20iA/L

1 Pages

-

FANUC 3D Area Sensor

5 Pages

-

FANUC Multi Group Motion

2 Pages

-

ROBOSHOT

19 Pages

-

FANUC Secondary Encoders

2 Pages

-

ARC Mate 100iD/10L

2 Pages

-

ARC Mate 100iD

2 Pages

-

LR Mate 200iD/7L (long arm)

1 Pages

-

LR Mate 200iD/7C

1 Pages

-

LR Mate 200iD

1 Pages

-

M-20iD/25

2 Pages

-

LASER C3000i-C

2 Pages

Archived catalogs

-

NCGuide

3 Pages

-

FANUC ROBONANO a-NMiA

2 Pages