Catalog excerpts

Oerlikon Fairfield can help you take your project from design to commercial success. Whether you are looking for hydraulic or electrically-driven systems, our experienced engineers and customer-centric approach will help you find the best solution to differentiate your product while exceeding your customer’s needs. With over ninety years of experience, the largest pool of engineering talent within our industry and over 700,000 square feet of modern manufacturing positioned to support you globally, Oerlikon Fairfield is the leading provider of gear and drive solutions. Fairfield’s E01H is a...

Open the catalog to page 2

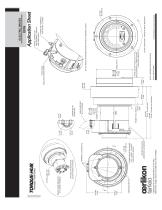

MOTOR END CAP IS UNPAINTED (ALUMINUM) FRAME MOUNTING HOLES: 0.375 - 16UNC - 1.00 DEEP 6 HOLES EQ. SPACED Catalog prints are representative of the units. Before nal design request a certied print from Faireld. DISENGAGE BOLTS TERMINAL COVER BOLTS OPTIONAL PM DC MOTOR (Contact Faireld for Details) BRUSH WEAR INDICATOR 3/16” SPADE TERMINAL NYLON CABLE TIE (BLACK) FRAME PILOT LENGTH [6.35] 0.250 CABLE SUPPLIED BY CUSTOMER STRAIN RELIEF INTERFACE OTHER MODELS ALSO AVAILABLE OUTPUT ROTATION - OPPOSITE INPUT ROTATION WHEEL MOUNT HOLES: M12 X 1.50 .900 [22.9] MIN FULL THREAD DEPTH 5 HOLES EQ....

Open the catalog to page 3

Peak Please Contact Faireld 3,600 RPM for A23 Motor 4,200 RPM for A24 Motor 2,600 RPM for S21 Motor U.S. 52 South P.O. Box 7940 Lafayette, IN 47903-7940 USA Telephone (765) 772-4000 FAX (765) 772-4001 www.faireldmfg.com Faireld Manufacturing Company, Inc. First in Custom Gears and Drive Systems Note: Specic models will change weights. Input Speed: Speed Limitations Torque-Hub is a registered trademark of Faireld. © 2003 Faireld Manufacturing Company, Inc. Bearing Curve 50 RPM Load (Curve) (Speed (Adjusted)) x (Load (Adjusted)) To adjust for loads and speeds other than shown on curve: Life =...

Open the catalog to page 4

Oerlikon Fairfield Key Competencies & Capabilities Gear & Drive Manufacturing • Spur, helical, bevel (straight and spiral) • Internal, external • Shafts over 3M in length, tapered serrations • 20mm to over 2M diameters • Complete gear grinding and finishing to AGMA Class 14 Heat Treatment • • • • • • Carburizing Nitriding Induction hardening Through hardening Shot peening Oil press / quenching Flexible Assembly • • • • • • Low volume or mass production Planetary drives Custom industrial drives Axles and transmissions Special large assemblies High volume paint facility • Continuous...

Open the catalog to page 5

No matter what kind of tracks you make... we have the drive solution. Oerlikon Fairfield U.S. 52 South P.O. Box 7940 Lafayette, Indiana 47903-7940 USA 765.772.4000 765.772.4001 (fax) fairfieldmfg.com Rev. 092810

Open the catalog to page 6All Fairfield catalogs and technical brochures

-

Tubing Injector Drives

6 Pages

-

Electric Drives

1 Pages

-

Custom Mining Drives

1 Pages

-

C026 Wheel Drives

1 Pages

-

Compact Drives

1 Pages

-

Marine Drives

8 Pages

-

Platform Drives

1 Pages

-

Custom Gear Capabilities

6 Pages

-

Global Engineered Solutions

16 Pages

Archived catalogs

-

High Speed Gearing

6 Pages

-

Torque Lock Brakes

2 Pages

-

The Capabilities Brochure

7 Pages

-

Custom Gears Capabilities

2 Pages