Website:

Fagus-GreCon

Website:

Fagus-GreCon

Group: Fagus-GreCon Greten GmbH & Co. KG

Catalog excerpts

Fagus-GreCon Greten GmbH & Co. KG P.O. Box 1243 D-31042 Alfeld-Hanover Phone Fax E-Mail MEASURE BEFORE IT COSTS Fire Protection Measuring Technology EN | R.04 | 2015.04 Subject to technical and country-specific modifications. © Fagus-GreCon Greten GmbH & Co. KG Measuring Systems

Open the catalog to page 1

QUALITY INNOVATION TRADITION

Open the catalog to page 2

Innovation is our Tradition. With this maxim, we refer to our innovative company founder and my great-great-grandfather who founded the FAGUS shoe last factory in 1911. Even then he had the courage to engage the visionary, but unnoticed Walter Gropius, who became an internationally renowned architect, to build his factory, which today is regarded as the origin of the modern age building. UNESCO designated it as a World Cultural Heritage Site in 2011. With an extensive restoration, it is in very good condition, still in operation and owned by the family. In 1970, our company experienced...

Open the catalog to page 3

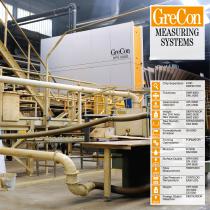

MEASURING SYSTEMS Chip Separation CHIPINSPECTOR Thickness Delamination Detection Weight Per Unit Area Raw Density Raw Density Profile Formaldehyde Emission Forming Optimisation Surface Quality Fibre Measurement Gas Pressure + Temperature CONTILOG EASYLOG Foreign Object Detection

Open the catalog to page 4

Your Benefit ■■ Check your production ■■ Ensure the quality of your production ■■ Improve your production processes ■■ Optimise your consumption of resources and raw materials Chip Separation Contaminated wood chips can cause numerous problems in downstream production processes. Nails can damage the steel belt, and rubber particles impair coating. Benefit The GreCon CHIPINSPECTOR separates foreign objects so that high panel quality and signifi cant savings of material and production costs are achieved. Foreign objects are even identified in material layers of up to 50 mm. Materials of the...

Open the catalog to page 5

Delamination Detection Thickness is an extremely important parameter for the production of panel-shaped materials. The intensity of the ultrasound signal that penetrates a wood based panel provides valuable information on the panel parameters. If the thickness is too high, valuable material will be wasted. If it is too low, there will be complaints, or downstream finishing processes cannot be conducted. Low ultrasound values point to faulty production quality (blisters). Values that are too good indicate valuable material or capacities are wasted. Production-related thickness fluctuations...

Open the catalog to page 6

Weight Per Unit Area/ Raw Density The weight per unit area gives information on the amount of the material used. The raw density profile is an extremely important parameter in the production of fibreboard. If the weight per unit area is too high, valuable material will be wasted. If it is too low, severe quality defects can occur (internal bond and screw holding capacity). If the profile does not correspond to the optimum shape, this will have serious effects on the panel qualities (e.g. internal bond). Benefit The material quantity can be optimised and fluc tuations reduced by a precise...

Open the catalog to page 7

Formaldehyde Emission Forming Optimisation The formaldehyde emission of wood based panels is subject to regulated limits. An even material distribution of the mat is an important pre-condition for a good panel quality. High fluctuations lead to waste of material, loss of quality and reduce the service life of downstream working tools. High emissions are unacceptable and can cause serious quality defects. With the new stricter regulations, existing measuring methods are often unable to provide reliable information. The reliable and exact measurement of the formaldehyde emissions ensures...

Open the catalog to page 8

Surface Quality Drying material is expensive, but essential. A high surface quality of panel-shaped materials is pre-condition for a high-quality product. This also applies to materials that are coated. If the moisture of the raw material is too high, there will be problems in downstream processes. If it is too low, valuable resources will be wasted. Benefit A precise, continuous measurement of the moisture saves resources and optimises production processes. Surface defects have to be detected as early and accurately as possible to avoid expensive faulty production and customer complaints....

Open the catalog to page 9

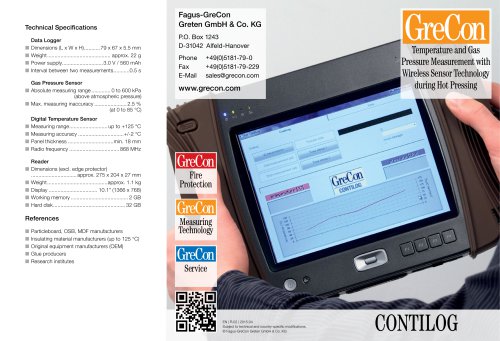

Fibre Measurement In fibreboard production, most of the energy is used for the production of fibres. The quality of the refiner discs is crucial. The correct adjustment of pressure and temperature within continuous presses is very important. The amount of energy required for the defibration process is high, and the evaluation of the quality of the refiner discs is difficult. Benefit The analysis of the proportion of big shives on the surface of the fibre mat allows conclusions of the required amount of energy. Even the timing of changing the refiner discs can be determined better. In this...

Open the catalog to page 10

Foreign Object Detection The weight is an important parameter for the production of panel-shaped materials. Foreign objects and particles of high density, such as metal pieces, hot spots or fibre lumps, can cause severe damage to production equipment. Without the panel weight, the amount of material used cannot be monitored. The raw density is also one of the most important parameters of a panel production. Benefit The amount of raw material used can be monitored by measuring the panel weight. This can be achieved most accurately using X-ray systems, which are also able to measure the...

Open the catalog to page 11

Personal customer service, combined with competence and experience, is our strength Customer service is one of our strengths. Beginning with the installation and start-up of your system, its daily use, maintenance work and troubleshooting, your personal GreCon technician accompanies your spark extinguishing system and/or your inline measuring systems through its whole operational sequence. This is done in close co-operation with your people. Global Service Team with more than 80 Experts Innumerable production plants in different industries worldwide are equipped with thousands of GreCon...

Open the catalog to page 12All Fagus-GreCon catalogs and technical brochures

-

SYN TEST PTM

9 Pages

-

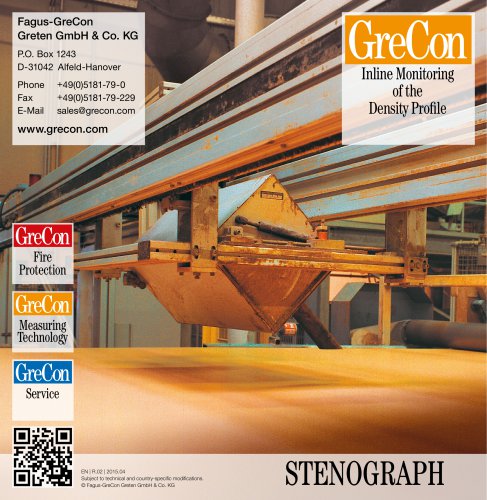

GreCon STENOGRAPH

11 Pages

-

GreCon SUPERSCAN SPR

6 Pages

-

GreCon UPU 6000

12 Pages

-

GreCon DMR 6000

10 Pages

-

GreCon IR 5000

7 Pages

-

GreCon MM 6000

8 Pages

-

GreCon DAX 6000

12 Pages

-

GreCon DML 6000

8 Pages

-

GreCon GS 6000

8 Pages

-

GRECON GA 6000

6 Pages

-

GreCon FIBERVIEW

10 Pages

-

GreCon EASYLOG+

6 Pages

-

GreCon CS 5000

10 Pages

-

CHIPINSPECTOR - FAGUS GRECON

6 Pages

-

GreCon BWS 5000

10 Pages

-

Fire protection

9 Pages

-

Measuring systems

5 Pages

Archived catalogs

-

SPM/SPL

6 Pages

-

Pipe Fire Extinguishing

2 Pages

-

BS7_Filter Monitoring

2 Pages

-

Measuring Systems

12 Pages

-

Service

4 Pages

-

Academy

2 Pages

-

BS 7 Press Protection

2 Pages

-

BS 7 Planer Protection

2 Pages