Website:

Fagus-GreCon

Website:

Fagus-GreCon

Group: Fagus-GreCon Greten GmbH & Co. KG

Catalog excerpts

Fagus-GreCon Greten GmbH & Co. KG P.O. Box 1243 D-31042 Alfeld-Hanover Phone Fax E-Mail Surface Quality Control for Inspection of Raw Panels Fire Protection Measuring Technology EN | R.01 | 2015.04 Subject to technical and country-specific modifications. © Fagus-GreCon Greten GmbH & Co. KG

Open the catalog to page 1

Your Benefit The Surface Inspection System SPR 6000 inspects the surface of each panel inline to ensure consistent sorting. The automatic image processing system guarantees 100 % inspection and allows continuous, consistent sorting by detection of surface faults and defects of raw panels. Detailed conclusions for upstream production process adjustments are possible through fault and statistics reports. Thus, not only sorting, but also the entire production process can be optimised. ■■ Reliable, objective, complete inspection of sanded panels ■■ Evaluation of sanding results (optically and...

Open the catalog to page 2

Automatic Surface Inspection The detection of faults and defects is done by two inspection systems that are integrated in the frame and inspect the panel surface with different lighting concepts. The inspection performance results from a combination of the results of both systems. One system is the basic module and uses lighting vertically from above. The other system uses inclined lighting and is called topological module. Faulty raw panel quality, bottom MDF, top particleboard The image data from these modules are combined, defective areas located and the faults and defects classified....

Open the catalog to page 3

Design and Modules of the System Basic Module Modular, lacquered steel frame for one-sided or two-sided inspection: ■■ Bottom frame ■■ Top frame ■■ Conveying tables (belt or rollers) before and after the scanner ■■ Different lighting modules for classification of different defects: ■■ Light patches (glue, water, …) ■■ Dark patches (oil, rubber, resin, bark, ...) ■■ Coarse chip in the surface, spreading faults ■■ Unsanded areas, rough areas, dust patches ■■ Cracks (in the surface) ■■ Break-offs at panel edge or corner ■■ Cross-stripes, sanding mistakes, chatter marks, holes Topological...

Open the catalog to page 4

Basic Construction and Layout The basic construction of the measuring system is a solid, closed frame. Doors allow easy access to individual measuring components. Slight overpressure provides optimum measuring conditions while cooling the light source. The lighting body is equipped with a quick-elevating motion to protect it against blisters. Layout of a sanding line with SUPERSCAN Sander Sander SPR 6000 Stacking

Open the catalog to page 5

Software Functions ■■ Software The visualisation software of all GreCon measuring systems is based on Windows. ■■ Network Connection For the data transmission to higher-ranking process control systems, different network connections, such as Profibus, are available. ■■ Visualisation The core of the software package is the visualisation software. It records, stores and graphically represents all measured data. The simple menu structure, which is identical for all GreCon measuring systems, makes intuitive and user-friendly operation possible. Detail of an identified defect: hole ■■ Database...

Open the catalog to page 6

GreCon measuring systems are equipped with GreCon online support SATELLITE. In the wood based panel industry, the SUPERSCAN SPR 6000 is used in the following applications in raw panel productions: This provides safe, simple and fast remote support when there is trouble or to check the system. Each online support is logged and stored in the system‘s history. ■■ After the sander ■■ After pressing or forming processes ■■ Inspection of goods received for further processing Installation in a production line

Open the catalog to page 7

Surface Inspection Report Report From To Job Wooden Decor - Post Cuts Classifications Date Defect Area GreCon SPR 6000 Alfeld, Germany Press 1 Class Position Boards Meter System Bottom Normal Decor Type Wandering Brightness Deviation / Defect Area 65 / 0,0054 in² Brightness Tolerance / Defect Area Bright 30 / 0,0046 in² Dark 31 / 0,0046 in² GreCon Testware GreCon SPR 6000 Alfeld, Germany Press 1 Board Classifications Total With Defects A - Quality B - Quality C - Quality Total With Defects A - Quality B - Quality Not Classified Date Defect Area Class Position System Bottom Normal Decor Type...

Open the catalog to page 8All Fagus-GreCon catalogs and technical brochures

-

SYN TEST PTM

9 Pages

-

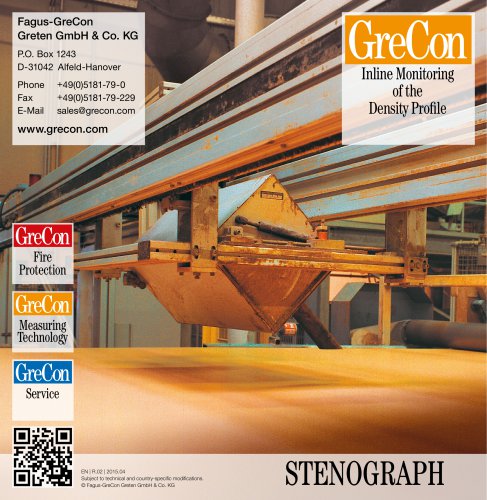

GreCon STENOGRAPH

11 Pages

-

GreCon SUPERSCAN SPR

6 Pages

-

GreCon UPU 6000

12 Pages

-

GreCon DMR 6000

10 Pages

-

GreCon IR 5000

7 Pages

-

GreCon MM 6000

8 Pages

-

GreCon DAX 6000

12 Pages

-

GreCon DML 6000

8 Pages

-

GreCon GS 6000

8 Pages

-

GRECON GA 6000

6 Pages

-

GreCon FIBERVIEW

10 Pages

-

GreCon EASYLOG+

6 Pages

-

GreCon CS 5000

10 Pages

-

CHIPINSPECTOR - FAGUS GRECON

6 Pages

-

GreCon BWS 5000

10 Pages

-

Fire protection

9 Pages

-

Measuring systems

5 Pages

Archived catalogs

-

SPM/SPL

6 Pages

-

Pipe Fire Extinguishing

2 Pages

-

BS7_Filter Monitoring

2 Pages

-

Measuring Systems

12 Pages

-

Service

4 Pages

-

Academy

2 Pages

-

BS 7 Press Protection

2 Pages

-

BS 7 Planer Protection

2 Pages