Website:

Fagus-GreCon

Website:

Fagus-GreCon

Group: Fagus-GreCon Greten GmbH & Co. KG

Catalog excerpts

Fagus-GreCon Greten GmbH & Co. KG P.O. Box 1243 D-31042 Alfeld-Hanover Phone Fax E-Mail Inline Thickness Measurement for Quality Assurance with Laser Technology Fire Protection Measuring Technology EN | R.02 | 2015.04 Subject to technical and country-specific modifications. © Fagus-GreCon Greten GmbH & Co. KG

Open the catalog to page 1

Your Benefit ■■ Fast and early detection of fluctuations in quality ■■ Production control within restricted tolerance limits ■■ No material required to be added for sanding = reduction of production costs (0.1 mm ~ 0.8 % material) ■■ Display of optimisation potentials after changes in production (intentional or unintentional) ■■ Measuring data to regulate the press Why GreCon ■■ Customer-specific system design ■■ High innovative capacity: more than 10 % of the employees work in the R & D division ■■ Worldwide customer service network: more than 80 service technicians on duty worldwide ■■...

Open the catalog to page 2

Design and Construction of the System The innovative frame concept of the thickness gauge includes an optimised frame construction and allows stable measurements (stable measured values in run-in processes) using carbon fibre components. The closed frame concept protects all components, such as cable and air channels, laser or compressed air lines, against surroundings. A modification of the roller conveyor (panel guidance) is only necessary in individual cases. Easily accessible inspection flaps allow optimum access to the measuring system at any time. The measuring heads are installed in...

Open the catalog to page 3

ct-Frame To achieve continuous system availability, the DML 6000 can be equipped with a ct-frame. Maintenance, diagnostics and repairs can be conducted during the running production. Additionally, the mobile construction of the system allows an escape run in case of big blisters and thus prevents the measuring system from being damaged. Measuring System Analysis (MSA), Type-1 Study User-Friendly, Simple, Robust and Accurate High availability, operational reliability and, above all, consistent measuring quality are ensured by the calibration with integrated self-diagnosis system and the...

Open the catalog to page 4

Edge Sanding Monitoring The edge sanding monitoring separately evalu- ates the beginning and the end of a sanded panel according to recipe-specific values. The results are transferred to the PLC by OPC via the data table. Combination with other Measuring Systems Since the thickness gauge is a modular system, it is possible to change the measuring requirements The system can be combined with the Ultrasonic Measuring System UPU 6000 and a Board Scale to provide a quality assurance station. This combination is primarily used after continuous © This threshold value determines the allowable...

Open the catalog to page 5

Software Functions ■■ Software The visualisation software of all GreCon measuring systems is based on Windows. The software of the DML 6000 consists of the following program modules: ■■ Network Connection For the data transmission to higher-ranking process control systems, different network connections, such as OPC or ODBC, are available. Profibus and Profinet are available on demand. Control console and frame of a DML 6000 ■■ Visualisation The core of the software package is the visualisation software. It records, stores and graphically represents all measured data. The simple menu...

Open the catalog to page 6

GreCon measuring systems are equipped with GreCon online support SATELLITE. Triangulation differential measurement: This provides safe, simple and fast remote support when there is trouble or to check the system. Each online support is logged and stored in the system‘s history. at 60 mm = measuring range 1 μm at 400 mm = measuring range 4 μm Triangulation against reference piece: at 60 mm = measuring range 0.5 μm at 400 mm = measuring range 2.0 μm Shadow method: at 25 mm = measuring range 2 μm at 60 mm = measuring range 3 μm The accuracy depends on the product and the surroundings....

Open the catalog to page 7

The DML 6000 is used in the following applications: ■■ Bitumen sheeting ■■ Gypsum board ■■ Rubber sheeting ■■ HR-foam board ■■ Wood based panel industry ■■ Scotch tape ■■ Plastic boards or endless plastic foils ■■ PVC flooring ■■ After the Press In the wood based industry, thickness gauges are combined with GreCon Ultrasonic Measuring Systems UPU 6000 and Board Scales to a quality assurance station. Data is recorded and evaluated by one central visualisation computer. Thickness measurement of impact sound insulation with the DML 6000 Thickness measurement of foam material with the DML 6000...

Open the catalog to page 8All Fagus-GreCon catalogs and technical brochures

-

SYN TEST PTM

9 Pages

-

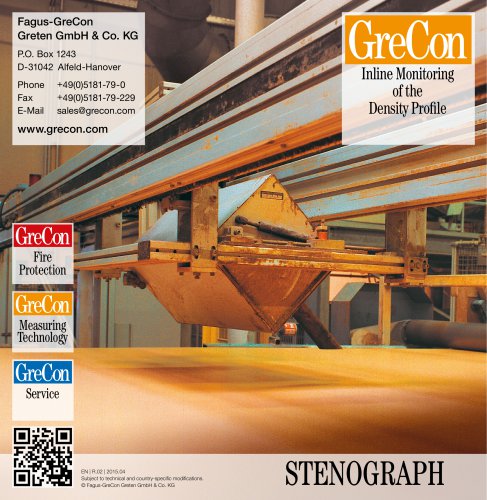

GreCon STENOGRAPH

11 Pages

-

GreCon SUPERSCAN SPR

6 Pages

-

GreCon UPU 6000

12 Pages

-

GreCon DMR 6000

10 Pages

-

GreCon IR 5000

7 Pages

-

GreCon MM 6000

8 Pages

-

GreCon DAX 6000

12 Pages

-

GreCon DML 6000

8 Pages

-

GreCon GS 6000

8 Pages

-

GRECON GA 6000

6 Pages

-

GreCon FIBERVIEW

10 Pages

-

GreCon EASYLOG+

6 Pages

-

GreCon CS 5000

10 Pages

-

CHIPINSPECTOR - FAGUS GRECON

6 Pages

-

GreCon BWS 5000

10 Pages

-

Fire protection

9 Pages

-

Measuring systems

5 Pages

Archived catalogs

-

SPM/SPL

6 Pages

-

Pipe Fire Extinguishing

2 Pages

-

BS7_Filter Monitoring

2 Pages

-

Measuring Systems

12 Pages

-

Service

4 Pages

-

Academy

2 Pages

-

BS 7 Press Protection

2 Pages

-

BS 7 Planer Protection

2 Pages