Catalog excerpts

FAGOR AUTOMATION for CNC Machines and High Accuracy Applications

Open the catalog to page 1

FAGOR AUTOMATION

Open the catalog to page 3

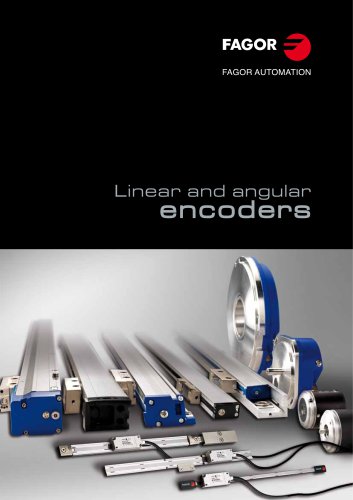

Linear, angular and rotary Over 30 years of continuous evolution

Open the catalog to page 4

Fagor Automation has been manufacturing high quality linear and rotary encoders using precision optical technology for more than 30 years. Over the years Fagor has created, developed and patented systems, components and technologies that allow us to offer best quality and features over the complete range of product utilizing innovative production methods. Hence making Fagor Automation the most efficient alternative in the world of feedback systems. Modern facilities and innovative processes In order to ensure quality and reliability in all its products Fagor Automation utilizes the most...

Open the catalog to page 5

Superior technology and innovative design Fagor Automation develops with maximum professionalism the three cornerstones in encoder design: optical design, electronic design and mechanical design that result in a stateof-the-art product. Optical design Leader in measurement technologies, Fagor Automation uses LED Linear encoder Projected light transmissive and reflective optics in its range of encoders. Photodiodes With new scanning techniques such as single field and threephase scanning that provide high quality signals that minimize interpolation errors. Electronic design Fagor Automation...

Open the catalog to page 6

Thermal performance Thermal Determined Mounting System (TDMS™) When designing the encoders Fagor Automation has taken into account the effect of temperature change on their performance. Most machine shops do not operate in temperature controlled environment hence affecting the accuracy of finished part. Using the TDMS™ system, Thermal Determined Mounting System which controls expansion/ contraction, Fagor linear encoders can deliver consistent accuracy and repeatability. For linear encoders more than three meters long, Fagor guarantees a thermal behavior identical to that of the machine...

Open the catalog to page 7

Technology The absolute measurement system is a direct digital measure of machine position. It is fast, accurate and does not require homing of the machine. The position value is available from the moment the machine is turned on and may be requested by the connected device (CNC) at any time. The absolute encoders provide direct measure of machine position without using any intermediate device. The positioning errors originating from machine mechanics are minimized as the encoder is directly mounted to the machine surface and the guide ways. The encoder sends the real machine movement data...

Open the catalog to page 10

Graduated glass /steel tape Cursor Thermal Determined Mounting System (TDMS™) Aluminum profile Sealing lips Reader head Air intake on the reader head Air intake at both ends Graduated glass disk reticule receiving photo-diodes convex flat lenses absolute sensor incremental graduation Angular and rotary encoders Angular encoders are used as angular movement sensors on machines that require high resolution and high accuracy. Fagor angular encoders reach 23 and 27-bit angular resolution equivalent to 8 388 608 and 134 217 728 positions respectively and accuracy levels of ± 5”, ± 2.5”, ± 2” and...

Open the catalog to page 11

Electrical output They are defined according to the communication protocol. Protocols are specific communication languages used by linear or angular encoders to communicate with the machine controller (CNC, drive, PLC, etc.). There are different communication protocols depending on the CNC manufacturer. Fagor Automation offers absolute encoders with different communication protocols compatible with the main CNC manufacturers on the market such as FAGOR, FANUC®, SIEMENS®, MITSUBISHI®, PANASONIC® and others. FAGOR systems They may be connected to Fagor systems via: 1. Serial Synchronous...

Open the catalog to page 12

SIEMENS® systems They may be connected to Siemens® systems via: 1. Serial Synchronous Interface - SSI These systems synchronize the SSI interface with sinusoidal 1 Vpp signals. Once the absolute position has been obtained through the SSI interface, the encoders keep operating with incremental 1 Vpp signals. These encoders are only valid to connect to SME 25 or SMC 20 modules of the Solution Line family. ABSOLUTE signals Transmission Levels Clock frequency Max. bit (n) T t 1 t 2 SSI Parity SSI synchronous serial transfer via RS 485 EIA RS 485 100 kHz - 500 kHz 28 1 µs + 10 µs > 1 µs 20 µs -...

Open the catalog to page 13

Range Analyze the application to make sure that the proper encoder will be selected for the machine. To do this, bear in mind the following considerations n Linear Installation Consider the physical length of the installation and the space available for it. These aspects are crucial to determine the type of linear encoder to use (type of profile). Accuracy Each linear encoder comes with a graph showing its accuracy along its measuring length. Signal The signal selection considers the communication protocols compatible with the main CNC manufacturers. Resolution The resolution of the...

Open the catalog to page 14

SSI + 1 Vpp FAGOR SSI + 1 Vpp SIEMENS®(*) FANUC® / MITSUBISHI® / PANASONIC® / FAGOR SIEMENS®(*) SSI +1 Vpp FAGOR / SIEMENS (*) FANUC® / MITSUBISHI® / PANASONIC® / FAGOR SIEMENS®(*) SSI +1 Vpp FAGOR / SIEMENS®(*) FANUC® / MITSUBISHI® / PANASONIC® / FAGOR SIEMENS®(*) SSI +1 Vpp FAGOR / SIEMENS®(*) FANUC® / MITSUBISHI® / PANASONIC® / FAGOR SIEMENS®(*) SVAF / SVAM / SVAP / SVAD SVAD + EC-PA-DQ SSI +1 Vpp FAGOR / SIEMENS (*) FANUC® / MITSUBISHI® / PANASONIC® / FAGOR ± 5” and ±2,5” FANUC® / MITSUBISHI® / PANASONIC® / FAGOR FANUC® / MITSUBISHI® / PANASONIC® / FAGOR ± 5” and ±2,5” FANUC® /...

Open the catalog to page 15

Model description: Specially designed for high performance environment requiring speed and accuracy. LA: Absolute linear encoders with SSI protocol for FAGOR and others. LAS: Absolute linear encoders with SSI protocol for SIEMENS® (Solution Line). LAF: Absolute linear encoders with FANUC® (01 and 02) protocol. LAM: Absolute linear encoders with MITSUBISHI® CNC protocol. LAP: Absolute linear encoders with PANASONIC® (Matsushita) protocol. LAD: Absolute linear encoders with FeeDat protocol for FAGOR and others. LAD + EC-PA-DQ: Linear and absolute encoders with DRIVE-CLiQ® protocol, for...

Open the catalog to page 16All FAGOR catalogs and technical brochures

-

FAGOR Innova DROs catalog

12 Pages

-

Linear and Angular Encoders

7 Pages

-

CNC 8060

16 Pages

-

8070 OL

12 Pages

-

CNC 8070

17 Pages

-

CNC 8055

16 Pages

-

CNC 8065

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages