Catalog excerpts

FAGOR AUTOMATION

Open the catalog to page 1

Fagor Automation Fagor Automation has been manufacturing digital readouts for over 30 years and has always kept ahead launching innovative products adapted to the actual machining requirements of conventional machines. This catalog is proof of that completing the DRO range with models that provide new and exclusive features. With solutions for each machine Innova series FAGOR DRO’s carry components created, developed and patented by Fagor Automation. Highly reliable products that adapt to the customers’ particular needs in order to improve the productivity of milling machines, boring mills,...

Open the catalog to page 2

With exclusive features The design of Fagor Automation’s 40i DRO models differs from the rest in that they have a 5.7” color TFT screen that offers a better view from any angle. They also include graphic programming assistance and 3D simulation providing intuitive and friendly operation. With state-of-the-art technology The DRO offers the user features that make his job easier, but what sets it apart in terms of machining accuracy is the feedback installed on the axes of the machine. Fagor Automation uses high quality, highly reliable optic technology to manufacture their linear and rotary...

Open the catalog to page 3

MILLING MACHINES AND BORING MILLS l/s/ngr the TFT screen of the Innova 40i, it is possible to select the X, Y, Z plane where the machining will take place, graphically see the steps to follow and simulate the end All that in the intuitive and friendly way that only FAGOR can offer. Graphic programming assistance: • Bolt-hole drilling • Linear drilling • Grid pattern drilling • Angle calculation in the plane I*|I«UI> Clraull The 40i P model includes the following features: • Part-program programming and backup • X, Y, Z, W machining plane selection • Up to 4 feedback axes and display on the...

Open the catalog to page 4

Common characteristics, M series Bolt-hole drilling The position of the holes is calculated automatically by entering the values requested by the DRO. Linear drilling calculation Calculates, memorizes the position and guides through the execution of linear drilling operations at any angle with respect to the axes. Tool radius compensation The tool radius is added to or subtracted from the position value when milling with a round tool depending on the machining direction. Corner rounding/machining of arcs To be used in simple corner rounding or curved surfaces in a plane defined by two...

Open the catalog to page 5

Specific characteristics: 40i The Innova 40i for lathes offers the operator graphic assistance that no other DRO can offer to program turning operations friendly and intuitively. 40i TS model This dro calculates and automatically varies the spindle speed according to the X axis radius while machining; thus providing optimum part finish, machining time saving and longer tool life. Its main characteristics: • Constant Surface Speed (CSS) • Spindle orientation with Teach-in • Override (50-150%) of the programmed RPM without interrupting the machining operation • Spindle speed control through...

Open the catalog to page 6

Common characteristics, T series Taper calculation The taper of a part may be calculated by entering the value of two points of the travel at the DRO. A parallel axis may be coupled with its pair at the same DRO display axis showing the combination of both on the Z axis display. When using more than one tool, each one will have a different origin (offset), these origins may be saved and recalled every time a new tool is changed. At every tool change, it saves a different origin (offset) that may be recalled by the operator. Preset in HOLD mode It is possible to preset on the axis the actual...

Open the catalog to page 7

Common characteristics, E series EDM mode: to set the activation level of the EDM program. Any level may be changed even during the EDM process. 6 digital outputs To control up to 6 penetration levels. 4 digital inputs For axis zero setting and emergency input. Electrode length compensation The outputs may be disabled during the EDM operation for measuring or replacing the electrode. 30i E model The 30i E model includes the following features: •Bolt-hole drilling •Linear drilling •Hold

Open the catalog to page 8

Common characteristics, Gereral series These models provide multi-purpose solutions, because they may be adapted to applications as different as auxiliary axes, metrology, woodworking machines, etc. General specifications of all Fagor Automation DRO’s nPreset function For the operator to enter values into the DRO and save them in its memory and recall them when needed. nDisplay of maximum, minimum coordinates and the difference between them nAxis coupling Parallel axes may be combined so a single axis display shows the addition/subtraction of both axes. nConnection to linear and angular...

Open the catalog to page 9

Comparison table M series milling machines and boring mills 40i P General series general purpose applications linear axes angular encoders incremental and distance-coded reference marks linear axis sag compensation travel limit alarm multi-point compensation (points per axis) d i s p l a y 5.7” color TFT screen LED display number of axes radius or diameter display mm/inch conversion fine / coarse resolution absolute / incremental feedback axis coupling f u n c t i o n s zero setting of the axes buzzer function number of references - part zeros axis preset tool compensation axis feedrate...

Open the catalog to page 10

Adapter plate • For mill ARM 300 model, 300 mm long ARM 500 model, 500 mm long • For lathe ARM-V-500 model 500 mm long Operating conditions Power supply protected against AC mains outage universal power supply with an input range between 85 VAC and 264 VAC. Frequency from 45 Hz to 400 Hz Operating temperature from 5 ºC to 45 ºC (from 41ºF to 113 ºF) Storage temperature from -25 ºC to 70 ºC (from -13 ºF to 158 ºF) relative humidity maximum 95% without condensation at 45 ºC (113 ºF) Sealing front panel IP54 and rear panel IP4X (DIN 40050) Product in compliance with safety and electromagnetic...

Open the catalog to page 11All FAGOR catalogs and technical brochures

-

GA series

60 Pages

-

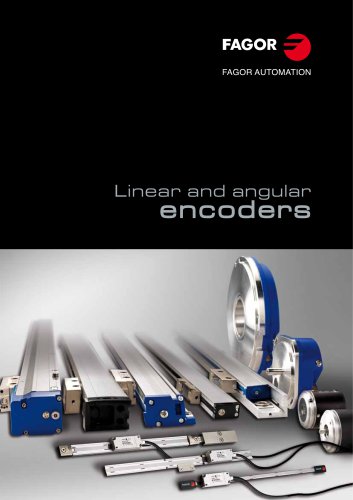

Linear and Angular Encoders

7 Pages

-

CNC 8060

16 Pages

-

8070 OL

12 Pages

-

CNC 8070

17 Pages

-

CNC 8055

16 Pages

-

CNC 8065

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages