Catalog excerpts

FAGOR AUTOMATION Easy as always, more power than even

Open the catalog to page 1

In the continued pursuit of improvement, Fagor Automation continues to evolve its products and now introduces the new 8065 CNC as an innovative and intuitive solution for the high performance machine tool world. The 8065 CNC increases machine productivity in two key performance areas. The first being the reduction of programming time due to the 8065 CNC’s intuitively focused operator interface. The second factor includes significant improvements in part finish resulting from incorporation of many high-speed machining features. Ergonomic and Robust Design A main characteristic of Fagor...

Open the catalog to page 3

Machining High speed machining High speed machining High speed part-programs are often generated utilizing CadCam systems. The 8065 CNC optimizes the captured points by smoothening the tool paths through polynomials (Splines). This polynomial interpolation produces an excellent part surface finish at high machining speeds. The complex tool paths are executed smoothly without abrupt accelerations or decelerations. The 8065 CNC analyzes in advance the tool path changes programmed for the part that is being executed. This allows for easier 4 adaptation to the dynamics of the machine thus...

Open the catalog to page 4

C N C 8 0 6 5 Optimizes machine efficiency Bode diagram The 8065 CNC allows for easy set-up of all types of machines while offering various adjustment tools that create optimum efficiency. The Bode diagram Is a tool for determining the machine’s frequency response. With this information, it becomes possible to filter vibrations produced from the resonance of mechanical design of the machine, thus allowing the machine builder/user to obtain best adjustment and stability. Circularity (roundness) test The circularity (roundness) test Helps improve the behavior of the axes when reversing their...

Open the catalog to page 5

Operation Close to the User’s needs The 8065 CNC offers truly intuitive operation based on pop-up type browsing coupled with an interface that the operator can easily adapt to his work environment. Designed with the shop floor environment in mind, the 8065 CNC manuals can be readily accessed from within the CNC. Another added advantage is the quick access to information with an automatic search system that avoids the need to consult indexes or search through chapters. Pop-up browsing Pop-up browsing The 8065 CNC offers a pop-up type menu system for immediate access to all the features &...

Open the catalog to page 6

Execution assistance Helps th e o pe r at o r s o l v e u n fo re s e e n s i t uatio n s Program restart after unexpected stop In long machining operations, if the machine stops unexpectedly due to external causes (a power outage, a machine error, etc), recovering the unfinished part may be cumbersome and difficult. The 8065 CNC helps the operator solve these situations by taking advantage of the machining performed without having to rerun the whole program. It is enough to do an automatic block search to the exact interruption point and resume execution. When observing imperfections in...

Open the catalog to page 8

C N C 8 0 6 5 dur ing ma ch i n i n g Stop requested by the user Stop requested by the user While machining a part, the 8065 CNC allows the user to interrupt execution of a program to check the machining status of the part and take the necessary actions. After detecting and analyzing any imperfections, it will be possible to: . Change the machining conditions set in the program without having to edit it again. . Make a tool change if it is worn out or broken. . Activate non-programmed auxiliary devices like the coolant. Once the necessary actions have been taken, the execution resumes with...

Open the catalog to page 9

Power In the vanguard of machine-tool technology The 8065 CNC obtains the best machining quality possible thanks to its wide selection of tools that provide tighter tolerances and the best surface quality. Also by using the adaptive control feature AFRS, it ensure the same part finish with a considerable reduction of machining time. 5-axis machining, RTCP The 8065 CNC manages standard kinematics (parallel kinematics, spherical spindles, rotary tables, etc.) and allows integration of specific kinematics for the OEM. Managing these kinematics combined with RTCP (Rotation Tool Center Point)...

Open the catalog to page 10

C N C 8 0 6 5 Adaptive Real-time Feed & Speed control (ARFS) The adaptive control feature optimizes machining speed, increases machine productivity, while maintaining mechanical integrity of the machine and that of the tools being utilized. Machine productivity is affected when the part geometry is complex and has lot of variations or if the hardness or rigidity of the material to be machined varies a lot. The CNC analyzes the machining conditions (power consumed, tool tip temperature, etc.) and adapts both the axis feed rate and the spindle speed for machining under the best conditions in...

Open the catalog to page 11

Integral solution With our product range Motors Fagor Automation offers a wide range of motors for a broad list of application requirements. Connectivity Small compact motors balanced for high speed starting at 3.7 kW and expanded to large machine, high power applications for up to 130 kW. They are designed for low noise & vibration levels all the way up to 15,000 rpm. ETHERNET Offered as an option, motors with dual winding (Y/Delta, star/triangle) and direct drive with a built-in hole in the shaft for automated tool cooling. (Coolant through the Spindle feature) USB Axes motors range from...

Open the catalog to page 12

C N C 8 0 6 5 Tele-diagnosis Feedback Systems Communication Digital/Analog Servo Drive Systems Motors 13

Open the catalog to page 13

Technical specif ications CNC 8065 CNC 8065 POWER Lathe Mill Lathe Mill 10” and 15” 10” and 15” 10” and 15” 10” and 15” 15” LCD monitor with Touch screen Optional Optional Optional Optional Touch pad Mouse integrated into the keyboard Optional Optional Optional Optional Spindle override potentiometer Optional Optional Optional Optional System configuration High resolution color LCD monitor 3 3 5 5 Up to 7 Up to 8 Up to 28 Up to 28 Maximum configuration of spindles 2 1 Up to 4 Up to 4 Maximum configuration of execution channels 1 1 Up to 4 Up to 4 From 300 MB to 30 GB From 300 MB to 30 GB...

Open the catalog to page 14All FAGOR catalogs and technical brochures

-

FAGOR Innova DROs catalog

12 Pages

-

GA series

60 Pages

-

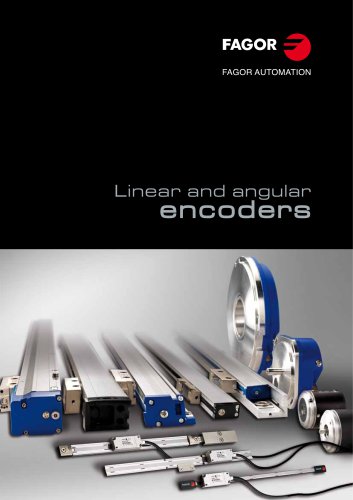

Linear and Angular Encoders

7 Pages

-

CNC 8060

16 Pages

-

8070 OL

12 Pages

-

CNC 8070

17 Pages

-

CNC 8055

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages