Catalog excerpts

FAGOR AUTOMATION

Open the catalog to page 1

CNC 8060 The ideal solution for precision milling, mold making, slant bed lathes and other high production machines The CNC 8060 offers two distinct ways of programming adapting to user’s machining needs: The ISO-G code language for large/ medium production runs (optimizing machining time) and the ICON conversational language for small production runs and prototyping (reducing programming time). Technical characteristics Axes + spindles Interpolated axes Execution channels Communication Bus Interfaces Touch screen Tandem axes and spindles Main microprocessor

Open the catalog to page 2

Solutions tailored for your machines IDCOW CCOW Fagor operator panel (JOG) with E-stop button and spindle potentiometer. Proprietary operator panel. Built for tough industrial environments The keyboards and monitors for CNC 8060 are designed to guarantee maximum sealing protection in any industrial The rear mounting mechanism provides protection against dirt and liquids and complies with IP65 (NEMA 12) sealing standard. The advance hardware design ensures long maintenance free life as the use of batteries and fans is eliminated. This sleek design minimizes heat dissipation and hence can be...

Open the catalog to page 3

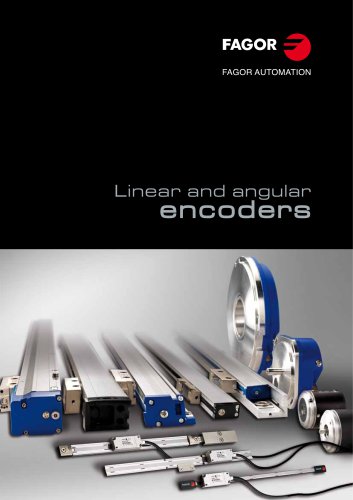

Completely integrated solu A unique Integrated platform for all your needs Fagor Automation’s unique integrated platform brings together every electronic element of your machine- the CNC , digital servo motors and drives, linear and angular feedback and ensures seamless integration, guaranteeing robust machine design and extreme performance to obtain maximum efficiency. These elements working in perfect harmony and intelligently selecting and executing the machining algorithms to exceed user’s expectations – EVERYTIME. Company network Ethernet TCP/IP Service Ethernet TCP/IP Feedback systems...

Open the catalog to page 4

Reliable, robust and durable: Total quality In order to ensure superior system performance under tough ambient conditions (temperature, vibrations etc.), various product testing methods like HALT-HASS process (unique, accelerated product reliability test methods) for detecting and resolving any product weakness are used ensuring very high product reliability at launch. Greater data exchange flexibility with external devices (USB, local network, web etc.) increases the threat of potential virus attacks from external intrusion. The CNC operating system is shielded with FBWF, a feature that...

Open the catalog to page 5

Completely integrated solu Offering complete solution Spindle Motors Fagor Automation offers a wide range of motors for a broad range of application requirements. Small compact motors balance for high speed starting at 3.7 kW and expanded to large machine, high power applications up to 130 kW. Designed for low noise & vibration levels all the way up to 15,000 rpm. Offered as an option, motors with dual winding (Y/Delta, star/ triangle) and direct drive with a built-in hold in the shaft for automated tool cooling. (Coolant through the Spindle feature). Axes motors range from 3000 rpm to 6000...

Open the catalog to page 6

Remote CAN I/O modules These modules are easy to install. Can be mounted at strategic points of the machine, thus having extra logic inputs and outputs distributed next to the devices. Using these modules makes it easier to lay out the elements of the electrical cabinet and therefore translates into reduced costs due to fewer cable/wiring being utilized. Hand wheels Fagor Automation offers various solutions for jogging the axis using hand wheels, allowing the machine operators to visually inspect the components while also assisting with the set-up. The intelligent hand wheels (with built-in...

Open the catalog to page 7

From the larger pieces to very small ones Utilizing various built-in tools the CNC 8060 provides outstanding surface finish while maintaining very tight tolerances. Gantry / Tandem axes / Feedback combination The CNC has been designed to easily adapt to all kinds of machine structures. When working with Gantry axes or pair of axes that must move at the same time and in synchronism, the operator must only program the movements of one of the axes and the CNC will manage the movement of the structure. Tandem servo systems are structures that have two motors mechanically coupled (slaved) and...

Open the catalog to page 8

We machine parts as small as human hair Nano-metric precision machining Inclined plane machining The CNC 8060 can manage standard kinematics (parallel, spherical spindles, rotary tables etc.) and machine specific OEM kinematics. The CNC allows machining in inclined plane without having to make any mechanical set-up adjustments. Once the axis/tool has been manually or automatically oriented, it is enough to define the inclined plane and carry out various machining operations like pockets, rotations, etc. The unique HSSA (high speed surface accuracy) machining system allows CNC 8060 the...

Open the catalog to page 9

Optimizing machine efficie Faster and more economical set-up tools for machine builders Setting up an advance CNC machine tool can be both challenging and very time consuming due to lack of right set-up tools. Fagor Automation offers a large library of set-up tools including on board oscilloscope, Ball bar test, Bode Diagram and servo tuning software like Finetune etc. Auto adjustment of axis (Finetune software) Set-up wizard Fagor Automation offers a quick set-up wizard for easier integration of its complete system hence substantially reducing the machine build-time. Based on the machine...

Open the catalog to page 10

maintenance tools Tele-diagnosis Tele-diagnosis The CNC 8060 offers tele-diagnosis software as standard allowing the OEM to connect to the machine user via internet to inspect, troubleshoot and repair the machine tool. This feature allows the machine builder to provide quick technical assistance without having to send a technician to user’s site hence eliminating unnecessary and expensive travel in many cases. Black box The CNC 8060 “black box” registers and saves all machine movements, operations and commands. The analysis of this data is a very useful tool in determining the cause of any...

Open the catalog to page 11All FAGOR catalogs and technical brochures

-

FAGOR Innova DROs catalog

12 Pages

-

GA series

60 Pages

-

Linear and Angular Encoders

7 Pages

-

8070 OL

12 Pages

-

CNC 8070

17 Pages

-

CNC 8055

16 Pages

-

CNC 8065

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages