Catalog excerpts

FAGOR AUTOMATION With the user in mind. More powerful than even

Open the catalog to page 1

CNC 8055 With the user in mind. More powerful than ever

Open the catalog to page 2

Fagor Automation has been providing Automation solutions to the Machine Tool market for over 30 years with the emphasis on large batch production, small production runs and prototype applications which requires a versatile, yet powerful CNC solution. The 8055 CNC provides perfect solution to both types of machining as it offers ISO G-code language highly suitable for high speed production based machining and the intuitive ICON key conversational programming language for small series or unitary work pieces where programming/set-up time is a crucial factor in determining the productivity of...

Open the catalog to page 3

Machining high speed machining During high speed machining operations, the 8055 CNC is in control of assuring smooth & accurate tool path without sudden accelerations or decelerations in order to obtain the most stable machining speed possible, thus avoiding part surface irregularities. High speed High speed The 8055 CNC utilizes advanced algorithms that are required in high speed machining operations to obtain a tool path that is identical to the part programmed from a blueprint. Combined with its advanced calculating power, a large lookahead buffer (200 blocks) and a high speed block...

Open the catalog to page 4

C N C 8 0 5 5 easier machine set-up Graphically assisted set-up user interfaces, such as the oscilloscope function mode or the geometry test help ensure the CNC makes up for the possible lack of performance of the mechanical system by considering the particular dynamics of the machine. Oscilloscope Oscilloscope The on-board Oscilloscope function is an assistance tool for optimizing the performance of the Servo System by simulating in real time the performance characteristics of the machine through various machining conditions. This data greatly enhances the OEM’s ability to choose the best...

Open the catalog to page 5

The ICON based operations of the 8055 has been specifically designed for operators of conventional machines who lack prior programming knowledge such as ISO G-code language. Fagor Automation's conversational language has been designed to make the operator's job as intuitive as possible, because of this; operators unfamiliar with Fagor CNC are capable of utilizing the 8055 CNC to its full potential in just a It offers quick and efficient access, through ICON hot keys to the various operations and canned cycles. Each operation or cycle has a specific graphic ICON hotkey. You may simply press...

Open the catalog to page 6

Intuitive browsing with hotkeys Edit / verify / modify Execute or simulate a single cycle

Open the catalog to page 7

Preparation help tool management Tools are managed before and during machining through simple intuitive operations that make For proper machining, the CNC has to know the dimensions of the tools. Fagor Automation offers several options for setting them: • After pre-setting of the machine, you may automatically enter that data into the CNC offset positions. • Using a master part with a known dimension or position. Simply touch off the tool on the part and the CNC will automatically calculate and load the offset thus the CNC now assumes the real part position of the tool. • Automatically...

Open the catalog to page 8

part preparation In serialized part production, in order to obtain repeatability in the positioning process of the new parts, the 8055 CNC helps the user run these operations fast, accurately and efficiently. Part preparation Zero offsets Part preparation Fagor Automation offers measuring cycles that help the user detect the exact position of the part on the work table. The 8055 CNC provides data such as corner positioning, center coordinates, part angle rotation, etc... Due to this data, the CNC has the ability to adapt the work coordinates to the actual part position, thus avoiding to...

Open the catalog to page 9

Programming ISO-coded language / ICON conversational language Fagor Automation offers various programming languages to allow for improved operator ease & efficiency. Programming in cycles ICON conversational language These programming languages may be combined when creating part-programs. ISO-coded language for large production runs where optimizing the program is more important considering cycle time reduction is an important aspect of the operation. ICON conversational language for small part-runs. This intuitive interface has been conceived for shops where set-up & programming time is a...

Open the catalog to page 10

Integral solution with our product range Spindle Motors Fagor Automation offers a wide range of motors for a broad range of application requirements. Connectivity Small compact motors balance for high speed starting at 3.7 kW and expanded to large machine, high power applications up to 130 kW. Designed for low noise & vibration levels all the way up to 15,000 rpm. ETHERNET Offered as an option, motors with dual winding (Y/Delta, star/ triangle) and direct drive with a built-in hold in the shaft for automated tool cooling. (Coolant through the Spindle feature). USB Axes motors range from...

Open the catalog to page 12

C N C 8 0 5 5 Tele-diagnosis Communication Digital/Analog Feedback Systems Servo Drive Systems Motoring 13

Open the catalog to page 13

Technical specif ications CNC 8055 FL CNC 8055 POWER Lathe Mill GP Lathe Mill GP 2 4 4 2 4 4 System configuration Basic axis configuration Maximum axis configuration 4 4 4 7 7 7 Maximum spindle configuration 2 2 2 2 2 2 5 5 5 8 8 8 1 MB 1 MB 1 MB 1 MB 1 MB 1 MB User memory (Compact Flash) 512 MB 2 GB w 512 MB 2 GB w 512 MB 2 GB w 512 MB 2 GB w 512 MB 2 GB w 512 MB 2 GB w Block processing time 3.5 ms 3.5 ms 3.5 ms 1 ms 1 ms 1 ms Maximum axis/spindle configuration User memory (RAM) 232/120 232/120 232/120 232/120 232/120 232/120 Maximum local digital I/O (Integrated model) 56/32 56/32 56/32...

Open the catalog to page 14

C N C CNC 8055 FL 8 0 5 5 CNC 8055 POWER Lathe Mill GP Lathe Mill GP Optional Optional - Optional Optional Optional Programming and operation Retrace function Collision detection function Standard Standard Standard Standard Standard Standard Simulation with execution time estimate Standard Standard Standard Standard Standard Standard Graphics with tool path lines Standard Standard Standard Standard Standard Standard Solid graphics Standard Standard - Standard Standard - Graphics for vertical lathe Standard - - Standard - - Conversational Optional Optional - Optional Optional - Profile...

Open the catalog to page 15All FAGOR catalogs and technical brochures

-

FAGOR Innova DROs catalog

12 Pages

-

GA series

60 Pages

-

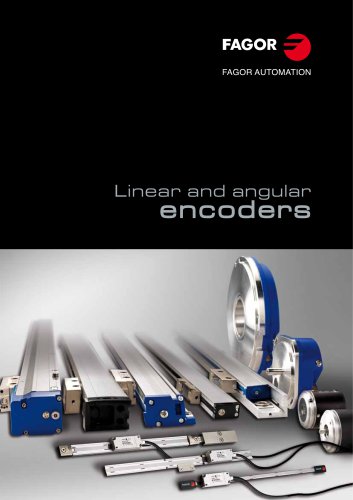

Linear and Angular Encoders

7 Pages

-

CNC 8060

16 Pages

-

8070 OL

12 Pages

-

CNC 8070

17 Pages

-

CNC 8065

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages