Catalog excerpts

The perfect solution for your needs Fagor Automation has been developing automation and control systems and manufacturing CNC's, servo drives, motors and feedback systems for over 25 years. The great versatility of their CNC's for adapting to various types of machines and their fully customizable interface make the 8070 CNC the ideal complement for all kinds of machines like press brakes, gear hobbers, grinders, machines for wood, stone, glass, etc. Fagor Automation's ample experience is manifest in their control loops, axis interpolations and specific algorithms for high precision...

Open the catalog to page 2

CNC 8070 OL for general purpose applications The 8070 CNC adapts itself perfectly to all kinds of machines: Grinders, punches, press brakes, saws, polishing machines, machines for woodworking, marble, laser, plasma, water jet, etc. When required by the application, milling and turning operations may be combined on the same machine with the possibility of using all the machining cycles. It offers filters that eliminate oscillations due to the machine's own frequencies and preventing them from negatively affecting the machining operations and reducing the mechanical stress on the system. By...

Open the catalog to page 3

Management of kinematics and inclined plane machining Several kinematics may be defined to better adapt to the requirements of the machine. It admits parallel kinematics; spherical, orthogonal and angular spindles; rotary tables and the combination of swinging spindles and rotary tables. It also admits specific kinematics used by specific machines and provides the right tools to define them easily. It is possible to machine in inclined planes without having to loosen and wedge the part. Once the tool has been manually or automatically oriented, it is enough to define the inclined plane and...

Open the catalog to page 4

Home search After powering up the machine, there is no need to move the axes to the reference point (home). Using FAGOR distance-coded feedback systems, the CNC assumes the new position by simply moving the axes 20 or 50 mm (depending on the linear encoder). There is no need to move the axes when using FAGOR absolute feedback systems. Tandem and Gantry axes Using Tandem axes in a rack-and-pinion system allows backlash compensation on large machines. With the CNC 8070 OL, it is also possible to associate the Tandem function with rack-and-pinion type Gantry axes for smoother movement and...

Open the catalog to page 5

CNC 8070 OL Product Numerical control (CNC) compact models The three models come with a central unit integrated into the monitor, 10.4" or 15" TFT screen, and a full keyboard with easy-to-understand symbols (icons), hotkeys for quick access to work modes and freely customizable keys to configure them according to the requirements of the machine. CNC 8070 OL 15” CNC 8070 OL 10.4” 420 (16.54) 325 (12.80) 206 (8.11) 350 (13.78) 119 (4.69) 350 (13.78) 70 (2.75) 140 (5.51) 325 (12.80) 420 (16.54) CNC 8070 OL 10.4” K 6 350 (13.77) 420 (16.53) 330 (12.99) 128 (5.04) 325 (12.80) 140 (5.51) 50...

Open the catalog to page 6

Mounting possibilities distributed inputs and outputs monitor/touch screen thin client RIOW series servo drive systems linear feedback systems modular models They consist of a central unit, a monitor and a keyboard, a touch-screen monitor and a QUERTY PC keyboard. all of them separate. Fagor offers separate 15" There are two modular central units, MCU and MCU- monitor+keyboards, although it is also possible to use PCI with an optional PCI bus.

Open the catalog to page 7

Distributed inputs and outputs These modules are easy to install, they are mounted at strategic points of the machine for having extra inputs and outputs distributed next to each device. They are distributed in groups and are connected to the central unit through the CANopen bus. Modules of both series, RI05 and RIOW, may be combined. Remote modules with CANopen protocol RIOW series Small remote modules with CANopen protocol Spindle motors Small asynchronous motors balanced for high speed. They cover a power range between 3.7 kW and 60 kW with very low noise and vibration levels. Axis...

Open the catalog to page 8

CNC 8070 OL Functions and Features PC-based open system. Windows® XP operating system. Block processing time < 1 ms. PLC execution time < 1 ms/K. 512 MB or 1 GB RAM memory 4 GB, 8 GB or 16 GB Compact Flash. Ethernet 10/100 Mhz T base. Configuration 15" or 10.4" color LCD monitor. Up to 28 axes (interpolated simultaneously) and 12 handwheels. Up to 4 spindles. Up to 4 execution channels. Axes and spindles may be distributed dynamically between the channels. Up to 4 tool magazines. Digital and analog interface. Sercos®, CANOpen and Mechatrolink 1-2 (optional). Programming language ISO code...

Open the catalog to page 10

Operation with channels Axis swapping. Spindle swapping. Communication and synchronization between channels. High speed machining Spline interpolation. Polynomial interpolation. Flow control instructions Block skip ($GOTO). Conditional execution ($IF) and ($SWITCH). Block repetition (#RPT) and ($FOR). Conditional block repetition ($WHILE) and ($DO). Coordinate transformation Kinematics, up to 6 different ones on a machine. Inclined plane movement. Tool perpendicular to the plane. Working with RTCP (Rotating Tool Center Point). Tool length and radius compensation. Programming assistance...

Open the catalog to page 11

plants headquarters subsidiary distributor Worldwide Automation w w w . f a g o r a u t o m a t i o n.co m FAGOR AUTOMATION shall not be held responsible for any printing or transcribing errors in this catalog and reserves the right to make any changes to the characteristics of its products without prior notice. Fagor Automation S. Coop. EUROPE Bº San Andrés, 19 – P.O.Box 144 E-20500 Arrasate-Mondragón, Spain Tel. 34 943 719 200 34 943 039 800 Fax: 34 943 791 712 E-mail: info@fagorautomation.es www.fagorautomation.com DE - Fagor Automation GmbH (Göppingen) Tel. 49 7161 15 6850 Fax: 49 7161...

Open the catalog to page 12All FAGOR catalogs and technical brochures

-

FAGOR Innova DROs catalog

12 Pages

-

GA series

60 Pages

-

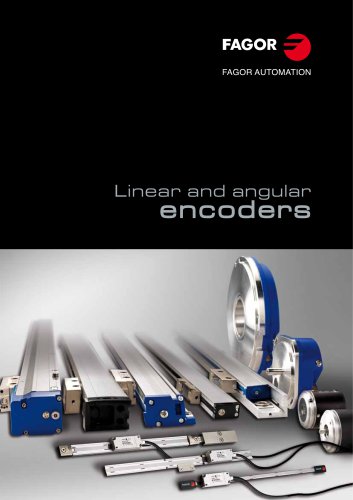

Linear and Angular Encoders

7 Pages

-

CNC 8060

16 Pages

-

CNC 8070

17 Pages

-

CNC 8055

16 Pages

-

CNC 8065

16 Pages

Archived catalogs

-

Brushless AC Servomotors

12 Pages

-

New FAGOR 8070 CNC

16 Pages

-

Spindle asynchronous motors

12 Pages

-

Digital Servo Drives System

12 Pages

-

Feedback Systems

8 Pages

-

programmable DRO’s

2 Pages

-

CNC Accessories

4 Pages

-

Positioning Controls

6 Pages

-

Fagor 8055CNC

8 Pages